- Natural materials

The bathhouse is a place not only to cleanse the body, but also to cleanse the thoughts. This room has long been considered magical, as it had the ability to fill the body with new vitality and return people to their original health.

Without insulation, a timber bathhouse will quickly cool down; to do this, it is necessary to insulate it both outside and inside.

But, as a rule, the presence of a bathhouse on the site implies not only rest and relaxation, but also hard work in caring for and insulating such an original structure. But how to insulate a bathhouse made of timber? After all, the functionality and comfort of the bathhouse will depend on high-quality insulation.

Basic insulation options

Today there are a lot of different types of insulation for baths, which are divided into artificial and organic. All of them can be used safely for timber buildings. But before moving on to considering the features of insulation, it is advisable to consider the insulation process itself. This job is done the same way no matter what material you choose.

Insulating a bathhouse made of timber is both a painstaking and interesting process. If you have certain work skills, you can cope quite quickly. But even if you have never done anything like this before, this will not prevent you from doing the work at a decent level.

Recommendations for choosing the thickness of insulation.

It is best to insulate the bathhouse during its construction. This is especially important to observe if you plan to use the bathhouse both in summer and in winter, and if the construction is carried out in a climate zone with harsh winters. In this case, insulation is divided into three types: internal, external and internal.

During construction, it is best to carry out in-wall insulation. It involves laying layers of insulation between the walls. That is, between the rows of timber it is necessary to lay insulation across so that it does not come out, but well protects the interior space of the sauna room.

External and internal insulation can be carried out even after the bathhouse has been built for a long time. Such insulation involves working not only on the walls, but also on the floor and ceiling, which is very important, since steam will reach absolutely all surfaces without exception.

Return to contents

Reduced thermal conductivity of brick

In the last decade, stone materials have been increasingly used in the construction of steam rooms, since their strength and wear resistance are an order of magnitude higher, but at the same time they cannot boast of a high thermal insulation rate. Faced with this, many people wonder how to insulate a brick bathhouse?

So, to achieve maximum results, you should start the procedure with floor insulation; for this you need to perform several successive steps:

- Creating a gap filled with air between the foundation and the floor covering by installing bars.

- Installation of layers of insulation between them and treatment of joints with construction foam.

- Covering with wooden boards or plywood.

- Formation of the main floor.

At the end of the first stage of work, a more fundamental one begins - thermal insulation of the walls of the steam room, this is also carried out gradually:

- Treatment with an antibacterial and antifungal agent, since increased moisture is the most favorable environment for the life and proliferation of harmful microorganisms.

- Elimination of all cracks by sealing with polyurethane foam.

- The sheathing is constructed from wooden blocks, after which it is attached to the brick wall.

- Laying insulation into the gaps of the resulting structure.

- Fastening materials using glue or umbrella dowels.

- Primer treatment.

- Laying out a layer of vapor barrier - it can be foil, kraft paper or glassine.

Recommended materials for insulating a bathhouse made of brick blocks:

- Layers of mineral wool and glass wool.

- Reed mats.

- Porous slabs made from cellulose or peat.

- Synthetic foam or penoplex boards.

Internal insulation

To insulate a log bathhouse as well as possible, you need to take care of both internal and external insulation at the same time. After all, only an integrated approach in this matter will give a good result. Let's consider all possible options for such insulation as briefly and accessible as possible.

Return to contents

Subtleties of roof insulation

How to insulate a bathhouse from the inside? An important point is roof insulation. Bathhouses made of wooden beams have pitched roofs with a small attic space. This construction technology allows for very good insulation.

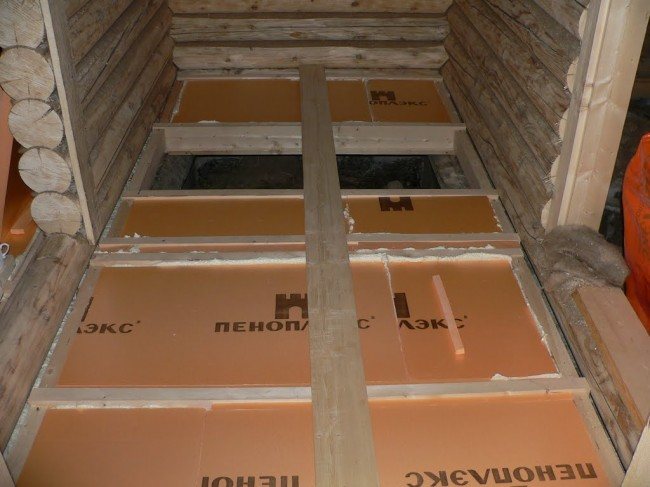

Scheme of floor insulation in a bathhouse.

So, first the attic space is cleared of debris and dust. Afterwards it should be dried thoroughly so that there are no traces of dampness. This is very important, because wood does not like dampness. Next, you need to provide a foam barrier. It is better to use greenhouse polyethylene, which is laid on the surface and attached to the tree with a construction stapler. Instead of polyethylene, you can use a special substance called glass hydroisol. It is more expensive, but the quality of insulation will be slightly higher.

Next, proceed to laying the bulk material. The main requirement here is lightness and fire resistance. Expanded clay would be an ideal option, as it is light and very cheap. It is better to prefer pebbles of medium fractions, which need to be poured in a layer of about 20 cm and carefully leveled.

You need to make a screed, which consists of a mixture of sand, water and cement. But its thickness should not exceed 2.5 cm above the expanded clay layer. And when it is completely dry and set, all you have to do is lay the main boards on top of the screed. The internal roof insulation for the bathhouse is ready!

Return to contents

Insulation of floors and walls

Another important point in internal insulation is working with walls. Here it is best to prefer a double method: using the main insulation, which will be fixed using a frame. To do this, first a metal or wooden frame is mounted on the walls using self-tapping screws. The space between the racks should be such that the insulating materials can be tightly inserted and fixed there.

Diagram of the insulation features of the bathhouse ceiling.

A vapor barrier film should be laid under the insulation, as well as on top of it, which is fixed with a construction stapler. This will keep the walls as reliable as possible. Then, on top of the film, you just need to cover the frame with either plasterboard or the main boards. If you prefer a metal frame, then it is better to use plasterboard. But on the other hand, drywall is worse than natural wood, since it is more susceptible to moisture.

When choosing a wooden frame, simply make the usual lining of the wall from the inside with thin boards. Just be sure to first impregnate them with compounds against bark beetles and exposure to high humidity and temperatures. Then the walls will not be afraid of anything.

It is also important to take care of reliable floors. If your bathhouse has not a wooden floor, but an ordinary concrete or stone floor, then it makes no sense to insulate it. Natural or artificial stone, as well as similar tiles, are an ideal choice for a timber bathhouse. After all, wood on the floor does not justify itself at all, since this surface will be constantly wet.

But even under stone or tile it is advisable to lay a layer of vapor barrier. This will be quite enough to ensure the reliability of the floor and its functionality. There is no need to use insulation here, as this will still have no effect. The insulation of the bathhouse from the inside is complete!

Return to contents

Selection and features of insulation

Glass wool is an excellent insulation for a bathhouse, as it is durable and quite cheap.

If in former times people resorted to the help of moss, hemp, and flax tow, now these materials are used less and less often. This is explained by their short period of operation. They are destroyed by insects, birds, and weather conditions. In addition, the caulking process is quite labor-intensive and takes a lot of time.

Red moss and cuckoo moss are often components of many modernized materials. However, these types of sealants must be subjected to an active drying process to prevent the wood from rotting. Still, finishing timber walls with ordinary moss is not easy.

Nowadays, natural insulation materials must be treated with special substances, which makes them more durable, easier to use, and protects them from the invasion of pests. Among them are flax batting and flax jute felt.

Good materials for successful thermal insulation would be perlite, glass wool, penoizol, and basalt wool. They do not burn, are environmentally friendly, safe, and resistant to moisture. Expanded polystyrene and polyurethane foam can create an excellent base for insulating a bath. They are practically weightless, durable, but quickly burn. Therefore, such basics are suitable for the waiting room.

Jute is in particular demand. It is characterized by a high degree of resistance to atmospheric influences, does not decay for a long time, and has a long service life. Insulating tiles include mats and slabs based on glass wool. Organic materials include straw, flax, and wood.

All cracks between the beams must be caulked.

Six months after the natural shrinkage of the building, the insulation of the bathhouse must be carried out according to the full scheme. To do this, the material placed between the beams should be caulked well. The seams should be neat and even. Then you need to make a vapor barrier inside the room. How to insulate a bathhouse so that it remains warm for a long time?

To do this, it is necessary to cover all walls and ceilings with special slabs that provide good thermal insulation. Then a base of vapor barrier materials is placed on this layer, which will prevent the appearance of condensation. The same effect is achieved in the thermos compartment.

Foil is used for the compartments intended for steaming and washing, and kraft paper is used in the dressing room. Sometimes they resort to using plastic film. Roofing felt and roofing felt are completely unsuitable for such purposes, because during the heating process they release an unpleasant odor and toxins.

To ensure that the seams of vapor barrier materials are securely fastened, special tape based on aluminum foil is used. Note that finishing the ceiling requires increased attention, because it is subject to increased vapor formation. Allowable gaps between the cladding material are 1-2 cm.

How to insulate a bathhouse? Pre-finished walls are covered with plasterboard, clapboard, and gypsum fiber. Visible cracks are covered with a layer of sealant. In this case, the bathhouse will be reliably protected from blowing.

The vapor barrier is laid after the insulation so that the foil is on the outside of the “pie”.

Nowadays, foamed polypropylene is used to insulate the inside of a bathhouse. Mainly designed for steam rooms, it can withstand maximum temperatures of up to 150 degrees.

Currently, the construction industry market has materials that have one side lined with foil, as a result of which heat is well reflected. Such a base can be an excellent vapor barrier (RockWool, Ursa, Isover). In order for the bathhouse to delight you with warmth and good steam, it is recommended to use 2 types of insulation: as a protective base from moisture and as a base that holds the air temperature.

To insulate a sauna, you can use the following scheme:

- Installation of the mounting frame. It is made from beams that are nailed to the walls of the bathhouse from the inside. The distance between them is equal to 55 cm.

- Assembly of insulating components.

- Treatment of gaps that appeared in the space between the frame and the insulating layer with construction tape.

- Installation of insulation.

- Processing the frame with clapboard.

As an insulating base for timber baths, you can use seals of different sizes. So, for treating an internal wall, 5 cm of coating is enough. An indispensable factor will be the presence of a layer of air between the base of the bath wall and the heat-insulating agent. Its permissible limits are reduced to 5 cm.

To prevent the fiber seal from failing at the right moment, it is laid in 2 layers. For the inner layer, the presence of foil is not necessary, otherwise it will accumulate excess moisture.

Log caulking

- Wooden baths made from natural logs were always caulked with natural materials, and moss was usually used for this purpose. The process itself is called caulking; this is when the material was manually pushed between the logs, which simultaneously compacted the logs and insulated the frame. The method itself undoubtedly has its positive and negative sides, it is quite labor-intensive, but, be that as it may, it has an enemy - the birds simply pull the substance out of the joints.

- Of course, such aggression must be resisted, and opposition was found - the walls began to be covered with siding. But in this case, a reasonable question arises - why build a bathhouse from natural logs if it is hidden by artificial cladding? Some may object to the environmental friendliness, the benefits of wood in a steam room, and so on, but all the same, the bathhouse is insulated from the inside, and we owe the effect obtained from wood to wooden lining!

- Fortunately, the industry now produces other types of materials that are not so easy for birds to handle. These are various tape insulation made of jute, flax and/or wool, so if you are hesitating what to choose, moss or jute for a bath, then remember about winged pests.

Sheep wool ribbon

The most interesting thing is that New Zealanders were the first to begin insulating their homes with sheep wool or felt, and Europeans have already borrowed this method from them. This material is made from natural raw materials, which are pre-cleaned with soap and/or soda (also find out how to insulate a bathhouse from the inside).

We invite you to familiarize yourself with Active oxygen for pool water purification: advantages and disadvantages of use

The fibers themselves have a special structure, the so-called cuticle, thanks to which they can adhere to each other when treated with water and steam.

Such a canvas can have different thicknesses and widths; the tape is sometimes treated with fire-retardant impregnations, but for wooden buildings such a safety measure does not make sense. The material itself is soft and pliable to the touch, absorbs moisture very easily, but also quickly releases it when heated, which allows you to maintain natural humidity, that is, it does not contribute to the formation of fungus and mold.

Felt made from sheep wool is used to insulate floors, walls, partitions, frame houses, and also as inter-crown insulation for log houses, in particular, steam baths. In addition to insulation and sealing, felt acts as an excellent sound insulator and, with all these advantages, its price is quite moderate, although much higher than its analogues.

Laying felt inter-crown insulation during the construction of a log house

Tape insulation made from natural fibers

An important quality of such material for us is its availability on the Russian market, where at the moment it is quite popular, which means we buy it. Its advantages include the ease of its use when assembling log houses, as well as the fact that the tape does not accumulate moisture, is a good sealant, does not cause allergic reactions and does not cause any interest among birds.

After laying, it sticks together, but this is due to its structure, which is somewhat reminiscent of Velcro for clothes - the smallest hooks interlock with each other, creating a single whole that looks very much like felt. The thickness of such a tape can vary from 5 to 15 mm, and the density from 300 to 800 g/m3.

The choice of insulation thickness will depend on how smooth the surface of the timber is - in some cases, the thickest tape has to be laid in two layers, which is what the installation instructions actually require.

Jute inter-crown insulation. Laying

First of all, let's understand what jute and jute fibers are, as some people mistake it for some kind of chemical derivative. First of all, Córchorus is a plant of the mallow family, native mainly to countries with hot climates such as Africa, Australia, India and Latin America. For clarity, you can see such fibers in everyday life, these are burlap and ropes.

Interventional tape is pre-fixed with a stapler

Currently, jute inter-crown insulation perfectly replaces caulking made of any material, but at the same time has a fairly low price. The tape is a strip with a thickness of 5 mm, 10 mm and 15 mm, having a dense and uniform structure. The insulation is laid on the beam and pre-nailed with a stapler so that it does not slip off when installing the wall.

After laying the timber, the jute is compacted and creates a fairly dense mass that can successfully withstand the effects of moisture and wind. Walls that are assembled using such insulation do not require additional finishing, since the seam is very smooth and has an almost perfect appearance. By the way, the jute tape, unlike others, is very smooth and does not have any bumps or gaps.

Roll (plait) with linen insulation

I hope there is no need to explain to anyone what flax is; one might even say that it is a national culture, although for some reason it is undeservedly forgotten. Due to its environmental friendliness, this material for inter-crown insulation of walls is absolutely harmless to health and does not create favorable conditions for the occurrence of fungus and mold (see also the article “Insulation of the roof of a bathhouse: selection of material and step-by-step installation”).

Linen as a gasket allows the walls to “breathe”; it randomly absorbs and releases moisture at the same rate, that is, it maintains the level of humidity in the environment (atmosphere).

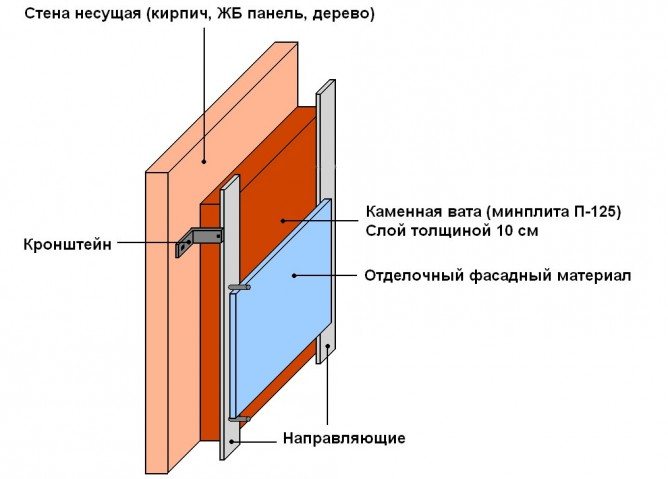

Facade insulation

Scheme for insulating the walls of a wooden bathhouse.

Let's consider the external (facade) insulation of a bathhouse made of timber. This stage is the most important, since here the walls will be exposed not only to internal, but also to external influences of environmental factors. The same materials can be used, but the process itself will be somewhat different from internal work.

In fact, everything is not so complicated here. There are only a few factors to consider. You need to choose the right time for insulation work. It is best to let it be summer, when the air temperature is high and the humidity is minimally low.

First you need to caulk the cracks between the beams so that moisture and air do not penetrate there. For this, natural materials are used that can be used loosely (that is, not slabs). There are two options for working. You can simply seal the caulked areas with small insulating materials, or you can completely finish the walls with slab insulation, which is better placed on anchors. It all depends on the climate and the foundation.

Let's focus on the most budget-friendly and high-quality options, consider both natural and artificial materials that can be used to work on a bathhouse made of timber with your own hands.

Return to contents

Natural materials

The most environmentally friendly natural material is moss.

Before insulation, it must be thoroughly cleaned of soil, dried and treated with special compounds against moths and other insects. Moss is used to caulk cracks outside. This is a fairly clean and high-quality material that prevents cold air and moisture from entering the sauna.

Tow can also be used for caulking. It does not rot or be damaged by insects, unlike moss. In terms of money it will be quite cheap. But tow is not so durable, since it requires constant replacement at least once every two years.

Jute with the addition of flax is also often used to seal cracks in timber baths. This is the most reliable material, since it does not rot, is not eaten by insects, does not deteriorate over time, and therefore does not require replacement. Jute is an expensive material.

Return to contents

Artificial materials

Expanded polystyrene is one of the most common artificial insulation materials. Produced by a well-known company, such material is capable of retaining heat quite well. But at very high temperatures it can release harmful substances in small quantities. Therefore, it is not recommended to use it for internal insulation.

Polyurethane foam is almost the same quality as expanded polystyrene. He is the best at insulating walls. But it also releases strong toxins. Therefore, it is better to use it in the form of a thin layer of spraying rather than individual slabs.

Mineral wool sheets with the addition of synthetics are the safest in this regard. It does not emit harmful substances, so it can be safely used for internal insulation work. But you need to be careful when choosing the thickness and specific manufacturer.

So, the main points of insulating bathhouses made of timber with your own hands and choosing a specific material are considered. How to do the work is up to you, because you can do it in different ways. But you must adhere to the above tips, then everything will go as quickly and efficiently as possible.

Insulation made of synthetic materials for baths made of timber

Synthetic materials for insulating a log bathhouse

Before you start insulating a bathhouse, you should take into account the fact that the use of synthetic materials for these purposes is highly undesirable. This is due to the fact that the bathhouse loses its healing properties. Despite this, each material is worthy of more detailed information.

Mineral wool

The main advantage of this material is that it is completely non-flammable. The disadvantages of mineral wool are its complete lack of durability and too high sensitivity to moisture. It is used not only for thermal insulation of baths, but also in the construction of many other objects. Mineral wool is sold in rolls or sheets. Mineral wool is very convenient and extremely easy to use. The fairly low price also stands out.

Penoizol

Penoizol is an environmentally neutral material that does not accumulate harmful substances. It is very easy and convenient to use, it is durable and reliable. Penoizol is not subject to rotting or burning, and does not attract insects and rodents, which diligently avoid it. Sales are carried out in the form of rolls, crumbly crumbs or sheets.

Expanded polystyrene

This material stands out among others in that it retains heat perfectly, although the thermal insulation indicator strongly depends on the company that produces it. The disadvantage of polystyrene foam is its flammability. When burned, styrene is released, which has slightly toxic properties. The material is durable and quite easy to use. The price of polystyrene foam greatly depends on the manufacturer and the quality of the material.

Polyurethane foam

Among all synthetic materials, polyurethane foam is the leader in thermal insulation properties. That is why baths treated with polyurethane foam are considered warm. This material is extremely durable, but is also highly flammable, releasing highly toxic cyanide. The walls are covered with it in the form of pollination. The price of polyurethane foam largely depends on the manufacturer and quality of the material.

Insulation of a bathhouse made of foam blocks

Thermal insulation of a bathhouse made of foam blocks has its own characteristics: the insulation on the outside must be attached using ventilated facade technology. The material must be reliably protected from moisture (to prevent the formation of rot and mold), with normal external ventilation. For such purposes, it is worth using polystyrene foam, basalt (mineral) wool, and jute felt.

There is also a special technology for attaching insulation:

- Small squares are fixed outside, which form grooves. The spaces between them should match the width of the material used.

- After inserting the insulation, all joints between it are covered with waterproofing material or construction tape. If necessary, the structure is additionally pressed with dowels. Basalt wool, by the way, does not need this. The mats themselves are elastic and hold their shape well.

- It is recommended to hide all insulation using rolled waterproofing material, which can be secured with thin slats.