Terrace and deck boards made of larch for a bath

Probably everyone will agree that it is even more pleasant after a steam room or swimming in a sauna font to step barefoot not on a cool, smooth tiled or concrete floor, but on a warm “living” tree. But to lay a wooden floor in a bathhouse, which will give you real comfort and last a long time, it is not enough to purchase an ordinary floorboard.

All elements of the furnishings and interior decoration of the bathhouse are constantly subject to the adverse effects of reasons such as temperature changes and high humidity, which is why the most stringent requirements are imposed on the flooring material. In addition, you will walk barefoot on the wooden floorboards in the bathhouse, so the coating must be environmentally friendly and completely non-hazardous.

Terrace board for a bath: pros and cons

In old public baths, the floors were made of concrete screed or covered with tiles. Concrete is not very pleasant to step on, it is cold and does not look aesthetically pleasing. The tile is sliding.

Recently, they began to lay a terrace board on the floor of the bathhouse, which has a number of advantages:

- Attractive appearance of the material, on which the cut patterns of natural wood are visible. There is an assortment on sale, with a variety of patterns and shades.

- The anti-slip layer of the lamella looks like fine and larger corduroy. For a bathhouse, it is very important that the decking surface does not slip, even when covered with water, which allows you to avoid injuries and falls. There is a variety with a smooth coating. The customer can make a choice according to his own taste and capabilities.

- There are hollow and solid boards, with different strength margins.

- The percentage of wood flour and polymer content varies, and the price depends on this. The polymer surface does not contain sharp chips or splinters. Walking on such a floor is pleasant, safe, and it does not get cold.

- The polymers included in the composition (polyvinyl chloride, propylene, polyethylene) guarantee the water-repellent properties of the material, resistance to rotting, swelling, and protect against attacks by rodents and insects.

- Parts made from this raw material are strong, wear-resistant, do not crack, do not deform, and do not swell from water. If necessary, it is possible to replace a separate lamella.

- Such floors are protected from sudden fire by impregnation with fire retardants.

- The material can withstand large temperature changes and is intended for use indoors and outdoors.

- Easy installation, thanks to the tongue-and-groove system, a variety of colors allows you to lay the floors yourself, according to your taste.

The disadvantages of decking for a bathhouse include the price. Even in budget options this is quite expensive material.

Slight expansion at high temperatures and humidity should be taken into account during installation.

Comparison of larch with wood-polymer composite (WPC)

At first, it is impossible to replace a natural, “living” tree with any artificial material. Not a single tree species growing in the Russian region can compare with larch in terms of strength and uniqueness of composition and structure. If wood of other species is deformed by temperature changes and, without proper treatment, quickly rots in conditions of high humidity, then larch, thanks to the high content of natural gum resin , practically “petrifies” from frequent contacts with water.

What material is best to make a floor in a bathhouse?

Since the temperature in the bath

at

floor

, usually does not rise above +30C, the choice of materials for the floor...

Decking composite board installation

Terrace

composite

board

installation What do you need to know about working with

decking

boards?

Terrace

…

Siberian larch has low thermal conductivity, therefore it will forever retain warmth and a comfortable local climate in the bathhouse, and at the same time it is not at all afraid of high temperatures, unlike, for example, linden, which a couple of years ago was placed everywhere in bathhouses.

Nowadays, such a material as decking made of WPC (wood-polymer composite) is being intensively advertised, but during use, a number of side effects appear almost immediately:

— the acrid smell of plastic that comes from the WPC when the temperature rises, and the bathhouse is a place where high temperatures cannot be avoided;

— in conditions of high humidity, mold and mildew may appear on the WPC decking;

- due to temperature changes and waterlogging, the WPC is deformed.

In short, a WPC decking board in a bathhouse is unlikely to last long and will not bring much benefit to your health.

Terrace board for a bathhouse on the floor: installation features

It is necessary to lay the floors in your bathhouse, taking into account some installation features:

- The purchased batch should be kept for about 72 hours at the place of future use.

- While the finishing material is undergoing acclimatization, the floors are leveled, treated with waterproofing compounds, and reliable water drainage is organized by arranging a drainage and slope of the site.

- The number of lamellas and fastening clips, screws is calculated in advance, with some margin. For fastening, clamps and self-tapping screws, standard tools for woodworking, are used.

- The logs are laid at equal distances of 40-50 cm. Holes for self-tapping screws are drilled in advance.

- The slats are laid on the logs, starting from the door, moving sequentially. The first board rests against the starting bracket. A gap must be created between the wall and adjacent parts to allow for thermal expansion.

- The ends of the boards at the joints should rest on the lamellas to maintain the integrity of the site.

Important! When making WPC, antiseptic, paint and moisture-proof solutions are added to the composition. But to enhance water repellency, after installation is completed, it is recommended to cover the floors with another moisture-proof layer and repeat the procedure once a year.

Oak wood does not warp or crack. In addition, oak has an amazing property: being in a humid environment for a long time, it becomes stronger and harder, and bog oak is most valued. The moisture and water permeability of oak is low due to its high density.

Properties of wood. Features of oak lining

Oak needs no introduction. Its wood has high hardness and strength and does not require confirmation of its performance qualities, recognized for centuries. Many experts compare the characteristics of other tree species with oak, taking it as a standard. At the same time, it is accessible and incredibly widespread.

Oak wood has a narrow yellowish-white sap; the core is yellowish-brown or dark brown. Large vessels are visible in the early spring zone of the annual layer in the cross section. And in wood formed at a later time, light radial stripes formed by small vessels are visible. Wide medullary rays and annual layers are visible in all sections. The lifespan of an oak tree can exceed a thousand years, and its trunk diameter can reach two meters. The older the tree, the better quality its wood. The oak core dies and is filled with special substances - tils. They serve as both a wood preservative and a poison against rot and insects. It is from the oak core that the highest quality and most durable lumber is obtained. These same tills have tanning properties and significantly make the wood heavier.

First of all, oak lining is made from natural raw materials, this in itself is a huge plus. If you don’t like the oak finish, you can choose from more than 200 types of wood. Coniferous wood species have a healing effect on humans due to the fact that they clean the air. Oak lining is not afraid of water, moisture and does not absorb various aromas, due to which it is often used in kitchen areas. In addition to the fact that oak looks gorgeous, it also has high levels of sound insulation and dampens the sound emanating from the room itself. This moment greatly affects a person’s mood. After all, tension and nerves do not immediately affect you, they can manifest themselves in the form of diseases, so the correct microclimate at home is an important point. Due to high competition in the construction market, oak lining is now available to everyone at a low price.

Advantages of oak lining

Oak finishing material is a board equipped with a special locking fastening consisting of a tongue and groove, which are joined when laying the material. The result is a continuous wooden covering. The main positive qualities of oak lining include the following characteristics:

- Aesthetics - the beautiful texture of the wood, which makes the product especially valuable. Attractive appearance.

- Elitism . The finishing with expensive oak paneling emphasizes the high position of the owner and adds luxury to the atmosphere. Possibility of creating a luxurious interior.

- Durability . With proper processing of wood, the lining turns out to be durable and moisture-resistant, and is not affected by mold.

- Resistance to high humidity.

Taking into account the latter quality, the oak finishing material in the photo is actively used for cladding bath rooms ( Finishing a steam room in a bathhouse ). Depending on the wood processing, the color of oak lining can vary - from light to dark brown. It is almost impossible to make the surface of oak trim perfectly smooth, but this texture is not a disadvantage.

Types and varieties of oak lining

Oak lining is most often used in the decoration of offices, reception rooms, and lounges - it is believed that it has a warm and calm energy, emphasizing the status of the owner. This type of finishing material is divided into three types:

• Extra. • Calm • Bleached oak.

Based on the name, it becomes clear that the material is of the highest quality - extra oak lining. This is an expensive material that has no defects. It is often used to decorate luxury bath complexes and work rooms in country houses. Extra has frost resistance, a long service life, and a high level of wear resistance. This material is considered the best among other finishing materials.

Calm oak lining is a narrow profile wooden board equipped with a locking system. On two opposite sides along the length of each board there are two elements: a tongue and a groove. If the conditions for fitting the ridge into the groove are strictly observed, the result is an absolutely flat, ideally geometric cladding surface with a tight fit of the elements to each other.

Bleached oak lining has a distinct woody structure and natural color. The noble appearance of the material allows it to be used to decorate the most sophisticated, elite interiors. Bleached oak lining is perfect for decorating a library, living room, dining room, and study.

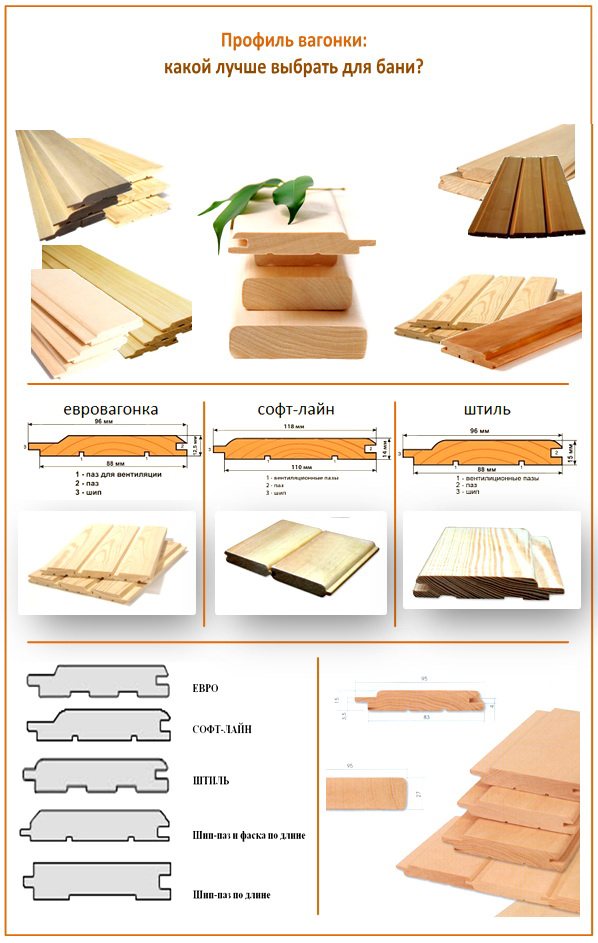

There are 3 standard lining profiles - “Euro”, “Soft-Line” and “Calm” . Also very popular is a type of lining such as imitation timber or boards tongue-and-groove along the length without chamfers, creating the effect of a solid surface.

If you decide to buy oak paneling, this is a profitable purchase and a long-term investment. You should not engage in amateur activities; it is recommended to trust work with elite finishing materials only to experienced specialists who know how to properly process and fasten lining made of ordinary and bleached oak.

Oak lining – price

When purchasing oak lining, pay special attention to its quality. Check not just a couple of slats, but the entire batch, otherwise some of the expensive finishing material may go to waste. The cut of the boards should be strictly in the direction of growth of the tree trunk. And not obliquely. The growth rings should not protrude too much from the lamella, otherwise it may break. The edges of the boards must be smooth, without bends, grooves, fringed areas, or cracks.

If you decide to buy oak paneling, this is a profitable purchase and a long-term investment. You should not engage in amateur activities; it is recommended to trust work with elite finishing materials only to experienced specialists who know how to properly process and fasten lining made of ordinary and bleached oak.

Installation of oak lining

Oak lining is a narrow-profile wooden board with a locking type of fastening. There is a ridge on one long side of the board, and a groove on the other. If you connect them correctly when laying, you get a perfectly flat sheathing surface without waves or cracks.

The most reliable method of fastening is to install the lining using nails. In order to avoid rust, it is recommended to select nails from special alloys that are not subject to corrosion.

You can use another option - a special solution that provides excellent adhesion of the material to the surface. Even with high humidity, the adhesive composition will not allow the cladding to peel off from the wall or ceiling. The only condition is that the installation of the lining should be carried out in the warm, dry season. The third option is to fasten the trim using the provided grooves and joints. In this case, the panels are held in place using baseboards and corners. In the middle, the canvas is supported by the adhesion of the boards to each other.

The use of oak lining in interior decoration

Traditionally, oak lining, the price of which corresponds to its quality, is considered the best material for interior decoration. This could be a director's office, a legal organization, bath complexes, home offices.

Oak lining is an excellent decorative material used for cladding walls, ceilings, doors, balconies, and verandas. For interior cladding of dry rooms. Cladding boards made from natural solid oak will create a warm and unique atmosphere in your home. A luxurious finishing of the interiors and facades of buildings will be given to you by the oak lining profile of the soft-line block house.

Often, bleached oak lining is also used in the decoration, which gives the room a certain color and mood. Wooden lining is a panel or wooden board used for mounting various surfaces, walls, ceilings, doors. The environmentally friendly material retains the natural beneficial properties of wood. It has a magnificent appearance and creates a beneficial atmosphere in the room.

For exterior finishing, you can use material pre-treated with special compounds. For this case, it is recommended to choose a material of greater thickness. The panels must be firmly fixed to the sheathing, since they can be deformed under the influence of atmospheric influences.

Thus, the scope of application of oak lining is quite wide . This finishing material can be an excellent decoration for any luxury interior. Thanks to its excellent performance characteristics, oak lining will be a wonderful addition to home decor.

Why is it worth buying unedged linden boards from us?

In our online store you can buy linden boards at a low price. We work directly with lumber manufacturers, which allows us to significantly reduce costs. With us you can carry out repairs with a minimal budget. We deliver throughout Moscow, the Moscow region and the Central Federal District. Our organization has its own transport - this allows us to significantly reduce the cost of delivery.

Unedged dry linden boards at our price are a profitable investment. We are located at the address: Moscow, Projected passage No. 6206, building vl1s1, MKAD 65 km. Contact us now and get good service and fast delivery.

Where is dry unedged linden board used?

The main area of application of linden is construction and renovation of premises. It is actively used for the manufacture of formwork frames when pouring the foundation. It is also important to use in the field of decoration. Linden boards are great as a design element and in the manufacture of lining. It has high quality and excellent appearance, which allows it to be used in decoration.

In addition, it is actively used in the production of various products. Many metalwork shops purchase linden boards for making furniture, wood decorations, cabinet elements, and wooden cutlery. Linden can withstand heavy loads with virtually no damage. Thanks to its moderate hardness, even high pressure does not cause significant damage that could not be corrected. Linden has excellent acoustic qualities. It can be used to make musical instruments such as guitars, violins, double basses.