Pine for bath

Log houses for baths made of pine are quite widespread today. This type of wood is relatively light and soft, making it very easy to process. Production of a log house for a bath from pine even for insufficiently experienced carpenters. A standard pine log house is subject to minimal deformation when it undergoes a complete drying procedure. The logs practically do not crack and always remain smooth.

The relatively low cost of pine logs makes this material very popular. Today, pine is considered the most affordable wood material. However, despite all the above advantages, pine logs have certain disadvantages.

One of the disadvantages of pine is its comparative instability to rotting processes in conditions of high humidity. Also, pine can be easily susceptible to the spread of wood fungus and all kinds of parasites. After some time, the structure of the logs may be damaged.

Coniferous trees produce resin. A relatively large amount of it can appear when the bath is heated. If you come into contact with hot resin, you can easily get burned or dirty. Vapors from straightened resin often create a suffocating odor in the bathhouse. Taking into account the above disadvantages, it is advisable to use a pine log house in the process of building a bathhouse only when using hardwood for internal cladding.

Features of the construction of a sauna log house from large diameter logs

When constructing a bath complex using large-diameter logs, the connection of logs in the crown can be carried out in several ways.

There are two main connection methods:

- “With remainder” is a variant of connecting logs in which the ends of the log house protrude outward. When using this assembly method, the locking elements are peculiar round recesses made on the body of the log. This type of assembly of a log bathhouse structure is less economical, since its use reduces the internal space of the bathhouse premises. However, this type of connection has one advantage: maximum thermal protection of the joints of the logs into a single structure.

- “Without remainder” is a type of log connection that uses the maximum length of the building material. When using this type of log connection, the likelihood of cold bridges occurring increases significantly.

In addition to those described, there are other types of connecting logs into a single structure, for example, the Norwegian and Finnish type of felling. The use of these types of log connections allows for maximum thermal protection of the connection points without the use of additional insulation.

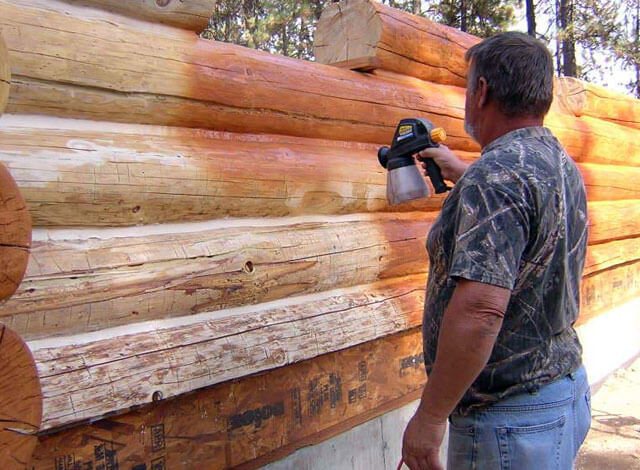

In some cases, if the owner of the land plot wishes, it is possible to trim the inner and outer sides of the logs in the log house to obtain smooth wall surfaces. Paring logs during the construction process allows you to get structures that will look very beautiful. The only drawback of this procedure is the need to carefully treat the hewn surface with special protective chemical compounds.

Spruce for bath

Spruce is also a fairly soft and light wood species. This material can be processed without much difficulty. Pine may darken over time. Compared to this species, spruce eventually acquires a white-golden hue, which will last for a long time. Spruce is also considered a fairly economical material for construction.

However, spruce also contains resins, which negatively affect the operation of the bathhouse. In addition, spruce resin can be released in larger quantities when the wood is heated. Therefore, such a bathhouse will also have to be lined from the inside with hardwood.

Larch

Larch is considered a coniferous species, but this tree differs from the previous mentioned species in its fairly high strength and durability. When larch dries, it can be comparable in hardness to oak.

A larch log house will last much longer compared to pine or spruce log houses. The resin of this tree species contains a natural anesthetic. It should also be noted that a larch bath has a beneficial effect on the body and helps prevent disorders of the cardiovascular system in the body.

Larch will be a wonderful material for homeowners who want to build a bathhouse that will last for many years. However, the cost of this type of wood is approximately 2 times higher compared to pine. Experienced specialists claim that such an overpayment is completely justified.

You should also remember that the steam room is finished from the inside, since the larch is impregnated with resin, which significantly increases the fire resistance of the material.

What diameter of log is needed for a bathhouse?

Before answering this question, let's decide what kind of bath we are talking about. The rounded material has a smaller diameter, since the unprocessed cross-section is measured together with the bark. Add 1 cm to the total cross-section of the rounded material. As a standard, for the construction of a bathhouse, material with a diameter of 20 to 36 cm is used.

Such a wide size range is due to factors that influence the choice of diameter for your bath:

- maximum winter temperature in the region;

- the bathhouse will be used only in the summer or all year round;

- size of the structure;

- wood kiln-dried or naturally damp.

At temperatures below -30 °C in winter, a bathhouse is built from material with a cross-section of 26–36 cm.

Southern regions with winter temperatures down to -15 °C can use a section of 20–25 cm.

For the middle strip, take a section no larger than 30 cm, but not less than 22 cm.

You can deviate from the norms and use a smaller cross-section, but then the bathhouse cannot be used in winter or will have to be additionally insulated.

When choosing a hand-cut log, you must add 1 cm to the given section.

Do not build a bathhouse on a summer cottage using large-section wood. The structure will be used only in the warm season, and its dimensions are small. So, for a 3x3 bathhouse on one floor, a cross-section of 18–20 cm is suitable. This will be enough to retain heat for a short time, and the steam room will warm up quickly.

A bathhouse at a summer cottage is assembled from a small diameter log.

For a bathhouse that is supposed to be used all year round, the diameter of the lumber is taken to be at least 24 cm. The foundation is installed with a massive strip or monolithic one. Especially if the wood is used with natural moisture.

When choosing a large bathhouse project with two floors or an attic, you need to understand that heating the structure will be more difficult. For better thermal insulation, logs are taken with a larger cross-section from 25 cm. You can use a trick and save money by building the first floor from a cross-section from 25 cm and an attic with a diameter from 20 cm.

A bathhouse with an attic and a porch is assembled from timber with a cross-section of at least 28 cm

For a small bathhouse there is no need to take a large diameter. The structure will warm up quickly and retain heat for up to a day. A diameter of 20 cm is sufficient.

For hand-cut wood, add 1 cm to the given size.

When building a wooden bathhouse, it is necessary to take into account the shrinkage of the structure. So a bathhouse made from hand-cut timber with natural humidity will shrink at least 15 cm in height. After natural drying or from a winter forest, the shrinkage will be at least 4–6 cm. These dimensions must be taken into account when building a log bathhouse from a log. When choosing a section suitable for a box height of 240 cm, subtract the shrinkage.

The shrinkage of chamber-dried rounded logs is minimal and reaches 3 cm. Therefore, you should not take too large a cross-section of wood.

The larger the cross-section of wood for building a bathhouse, the higher the price for the material and assembly work will be. But you should not save if you are building a bathhouse for many years. Factors when choosing a diameter must be taken into account not individually, but collectively. So, when building a bathhouse from small rounded wood in the northern region, it is better to use chamber drying.

Cedar

A cedar bathhouse is considered a real luxury, since this type of wood is considered one of the most expensive. Today, large volumes of Siberian cedar are exported, so bathhouses equipped with cedar are considered elite buildings.

The properties of cedar wood are truly unique. Since the structure of this species is fibrous, after drying the logs practically do not shrink, crack or bend. Compared to other species, cedar does not rot as quickly and is resistant to high temperatures and high humidity.

It should also be noted that a cedar log house has a high aesthetic appeal. The logs are distinguished by a noble shade and a rather beautiful structure. Cedar wood is impregnated with essential oils. A sauna built from cedar can have an aromatherapy effect. That is why cedar is considered one of the most expensive materials for equipping a Russian bath.

Hardwood

To prepare a log house of hardwood, you can use second-grade logs with a diameter of 12-24 cm and a length of 4-6.5 m. When the walls of the log house are longer than the logs, the design can be complicated by internal partitions.

The following materials can be used to build a bathhouse:

- Maple;

- Birch;

- Aspen;

- Linden;

- Beech;

- Ilma;

- Willow;

- Hornbeam.

Yasen is not resistant enough to damp areas. Oak is used for the construction of the embedded crown.

Aspen is considered to be insufficiently aesthetically attractive and too soft a material. Since such a rock grows quickly, its strength characteristics do not have time to increase. The wood will gain the thickness required for the construction process very late. By this period, the trunk begins to crumble from the inside.

However, aspen will remain strong for a long time if it was cut in good condition. An unattractive protective film can be formed on the treated surface of an aspen log, which has a beneficial effect on the condition of the wood.

The main qualitative characteristics of an aspen log house should be considered:

- Moisture resistance;

- Low flammability;

- Most pests do not spoil this breed;

- Affordable price.

Aspen log houses are quite widespread. You can purchase a fairly large volume of wood, select suitable logs, and use the rest to light the stove. When an aspen frame is sanded, it begins to look very attractive. The steam in an aspen bathhouse is much softer compared to the effect obtained from a pine log house.

Advantages and disadvantages of a log bath

Light weight and environmental friendliness are considered the main distinguishing properties of any wooden house. Log sheets have their own distinctive features. It is necessary to consider certain properties in which a log may be inferior to a wooden beam:

- The construction process from such material takes longer and involves minor difficulties.

- The layout of the bathhouse should always be made taking into account the length of the log.

- In the area where the crowns meet, the width of the groove should correspond to the thickness of the wall and, accordingly, 0.5 of the total diameter of the log. This has a negative impact on the heat retention properties of the room.

Advantages of building a bathhouse from a log frame:

- It is possible not to equip the building with cladding, since the joints of the crowns will always be closed, and the external appearance of the building will be quite attractive.

- Unlike timber, a log will not crack all the way through the middle.

The growing area has a positive effect on the properties of the wood used. The density of wood increases if growing conditions are harsh enough. The intensity of growth of the formed annual rings and the tree trunk is also taken into account. There are opinions that it is advisable to use wood for the construction of buildings in the region where it once grew.

For example, in the Arkhangelsk region, a log house for a bathhouse is often taken from the northern forest. These trees are in quite high demand in the area.

Elimination of gaps between the elements of the bathhouse frame

There is no need to go into detail to explain the place the bathhouse occupies in the lives of our compatriots.

There are whole traditions associated with them and preventive procedures. Just remember the legendary film “The Irony of Fate” - this is a vivid example of the importance of the bathhouse for our citizens at that time. Such buildings appeared in our culture a very long time ago, and the first written mentions of them can be found in the Bible. In a word, if you want to relax your body and soul, tone your muscles and remove toxins, then you are welcome to the steam room. And if you have free space on your plot of land, then this is just great, because in this article we will tell you how to build a bathhouse from 3x3 timber with your own hands.

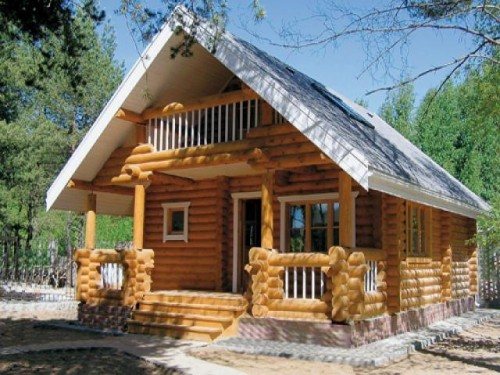

Bathhouse appearance

Advantages

I would like to highlight for you the main advantages of such buildings:

- Short construction time;

- All stages of wall construction can be completed independently without outside help;

- The shrinkage of such a structure is minimal and is within 100 mm;

- When making a bathhouse, you only need to buy beams, and the frame is made on site. This is even preferable, because it is better not to buy a ready-made log house, since it is more susceptible to distortions;

- Rounded logs have a high cost, and the price of timber is much lower. Consequently, the cost of the entire building will be more acceptable;

- The dimensions of the building can be very different; in our case, we are considering bathhouses made of 3 by 3 timber.

Construction of a bathhouse

In the following paragraphs we will look at the construction stages necessary to build our bathhouse.

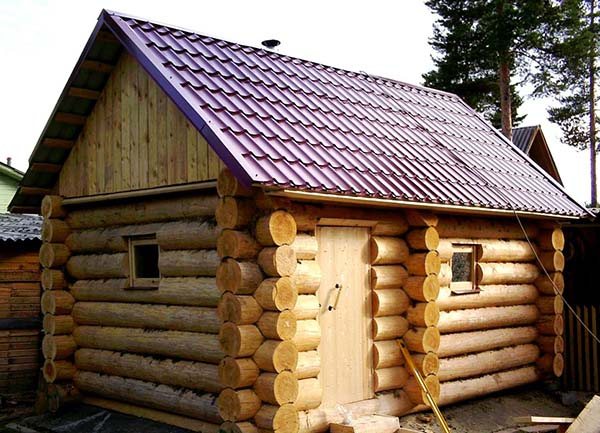

Photo of connections at corners

Have you decided to build a wooden sauna yourself? The structure can be made from different materials: timber, logs or rounded logs, and each method has its own characteristics.

It is easier to build a bathhouse from timber than from logs; it is less susceptible to shrinkage. And the price of timber is less than rounded logs, so this material seems to be a priority at first glance. Whether this is true or not, we will consider in this article.

The photo shows the finished bathhouse

It is better to harvest wood in late autumn or winter. The cut tree must “rest” for at least a month, only then can it be processed. First, the logs are cleared of bark, and in order to avoid cracking, strips of bark about 15 cm wide must be left at the ends of the log.

Proper storage of timber

Advice: If you purchase timber, choose winter-harvested material.

For several lower crowns of the bathhouse frame, it is better to use hard wood - larch or oak, treated with antiseptics. They are less susceptible to rotting. Subsequent crowns can be made from other conifers (pine, cedar, spruce).

How many cubes of timber are needed for a 3x4 bathhouse depends on the project, but usually it is 6 - 7 cubic meters. Pay special attention to the process of rejecting materials.

Cracks are not allowed

Timber defects that cannot be tolerated:

- cracks (as the log house shrinks, they can expand, which will lead to its rotting);

- signs of rotting on the surface of the wood (blue);

Blue discoloration indicates decay of the material

- tree damage by pests (wormholes).

In the photo there is a wormhole

Advice: To prevent contamination of high-quality wood, all rejected material must be burned.

Foundation

The foundation of a bathhouse made of 3 by 4 timber can be strip or columnar.

- To install a strip foundation, formwork is placed around the perimeter of the bathhouse to a depth exceeding the seasonal freezing of the soil, reinforcement is installed and filled with concrete. To protect against dampness, the foundation should rise 0.5 meters above the ground. Inside the foundation perimeter, crushed stone or sand is filled.

Strip foundation

- The columnar foundation can be made of brick. To do this, it is necessary to place pillars in the corners around the perimeter and in the places of the planned internal load-bearing walls. You need to make a reinforced concrete “cushion” under the pillars. The distance between the pillars should be about one and a half meters.

Columnar foundation

Note. These options are not exhaustive instructions.

Construction of a log house

Nowadays, developers are actively building bathhouses from 6x4 timber with their own hands, since these dimensions make it possible to freely accommodate the most important rooms - a locker room, a washing room and a steam room. However, before work, a material calculation must be made to determine the cost column.

Without preliminary calculations, deciding to build this structure is very difficult.

We suggest you familiarize yourself with How to properly soak a bath broom

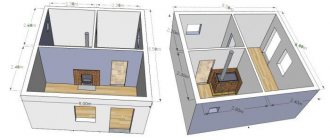

This is how a bathhouse made from 6x4 timber can be designed.

In the process of calculations, you will have to understand how much 150x150 timber is needed for a 6x4 bathhouse, but in addition to the main material, you will need to make calculations of other parameters. This primarily concerns the foundation and roofing. As for the remaining points, they are of secondary importance (see also the article Projects of wooden baths: a review of ready-made solutions).

There is an opinion that a log house has a lower cost than one built from profiled timber. The comparison is made specifically with profiled timber, since its performance characteristics are much higher: the processing of the material has been improved and special locks have been installed that enhance the adhesion of the elements.

When using a 20-centimeter beam, you can obtain a similar wall thickness and crown height. If 20-centimeter logs are used, then they are connected by selecting a 10-12-centimeter groove, which will be proportional to the thickness of the wall. Accordingly, the height of the crowns will not be 20, but only 10-12 centimeters.

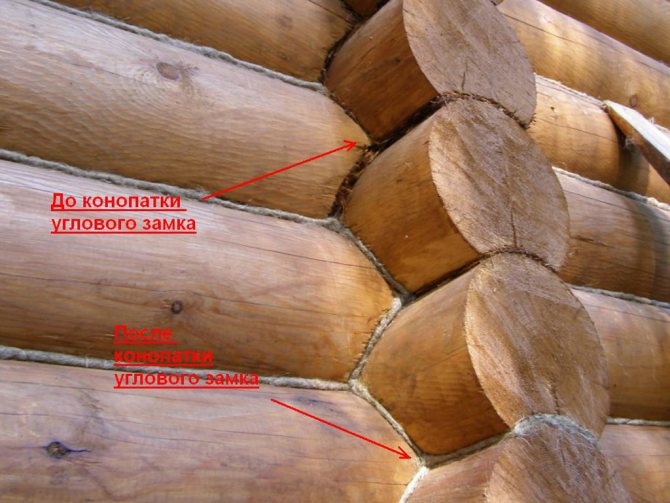

The most important step in the process of building a log bathhouse with your own hands is eliminating the gaps between the structural elements. The reason for their occurrence is the impossibility of creating a bowl for the crown in such a way that its shape fits perfectly with the log being laid. When the material dries, these cracks widen, which looks unsightly and worsens the performance characteristics of the bathhouse.

These cracks need to be sealed - caulked (for more details: “What and how to properly caulk a bathhouse - practical advice from a master”). They use a special tool called a “caulk”, which resembles a small flat spatula, and a hammer. Fill the gaps with moss or tow. By tapping on the handle of the caulk, you can compact the insulation as much as possible and achieve maximum protection of the premises from the penetration of cold air masses into them.

There is a construction option where the crowns are initially laid on a layer of moss. In this case, upon completion of construction, remnants of insulation will hang from the logs, which attracts various birds. Any remaining moss should be compacted into the cracks in the same manner as described above. But you will still have to caulk the cracks after 5-6 months, since the gaps will not be completely eliminated.

In the case when jute tape or tow is used as a layer between the crowns, the building needs to be caulked only six months after its initial shrinkage. Then you can begin installing window and door units. The second time the caulking procedure is performed after a year, unless, of course, the log house was lined on the street side.

What to take into account during construction

You need to understand that the chosen location on the site near the house is of great importance for the future construction of the bathhouse. The best place for construction will be an area located near a well or reservoir. Experienced bathhouse attendants say that clean water from a lake or river is excellent for building a bathhouse. Well water is much more hard.

If you place a bathhouse in this way it will be difficult. An additional option for normal design is a swimming pool with a depth of approximately 1.5 to 2.5 m. An additional advantage is the location of the bathhouse in an area that is best visible from the window of a residential building. In this way, it is better to control the condition of objects on the territory.

The Ministry of Emergency Situations and firefighters must agree with the homeowner on the location of the future bathhouse. It is also advisable to resolve this issue with the SES and the district department for construction and architecture. In accordance with existing standards, the normal fire safety distance from other construction sites should be at least 8-10 m.

It is advisable to choose the highest plot of land on your territory for a bathhouse. If such a possibility exists, the existing communications in a particular area can be converted into a water supply system. When designing a bathhouse in a rural area, it is advisable to create not two rooms, but to build a soap room separately. This will make the process of washing clothes and other household chores much more convenient.

If we consider the suitable dimensions of a log house, you can use 2.5 - 4.5 m for a regular wooden bath. In such a room, from 3 to 6 people will be comfortable at the same time. It is much more convenient if the soap station is equipped separately.

Individual features of the process of construction and operation of a log house

When a bathhouse is built from planed logs or timber, the biggest problem for the owner is the low resistance of the wood to moisture. You can, of course, treat the surface of the log house with various chemicals, but many owners are reluctant because they fear for their health.

It is possible to structurally protect wood from moisture with the help of well-organized ventilation:

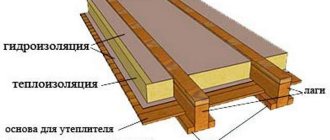

- When pouring a strip foundation (the most popular), special holes (vents) should be made in it. The air entering there will ensure quick drying of the floors;

- When laying the first crown, you need to place a waterproofing layer under it. You should not use rolled roofing felt, since it has an extremely short service life at its maximum characteristics. It is best to use waterproofing fiberglass materials or fiberglass. In common parlance they are called euroroofing felt and there must be no topping on them. The service life of such material reaches 10-15 years. Naturally, its price is higher, but the performance characteristics are worth it;

- The lower crown in the structure must be treated with an antibacterial compound, since it will be located below the floor level of the room and will be exposed to maximum exposure to natural factors during operation. Visitors to the bathhouse should not be afraid of fumes from the composition used for treatment, since high-quality underground ventilation and average temperatures will not create the desired effect for moving air masses into the log house;

- It is important to install the water drainage system in the washing room and steam compartment very well, since any mistakes can lead to undesirable consequences. After putting the bathhouse into operation, it will be very difficult to fix anything;

- ventilation in the steam room itself must also be of very high quality. It’s better for the room to cool down a little faster than, on the contrary, for moisture to destroy everything around it. It must be dried after each procedure. It will be enough to throw some firewood into the stove and open all the windows and doors so that the moisture is eliminated as quickly as possible.

We invite you to familiarize yourself with the sand block bathhouse, the pros and cons

If you are laying a log house for a bathhouse with your own hands from a log, then you should know about one more worst enemy of wood - wood borers. Insects greatly damage building materials. You can protect yourself from them by applying special impregnations, but their use is safe for the person himself in all rooms except the steam room.

Any evidence that woodworms have attacked the timber of a log house should be responded to promptly. You need to heat the sauna dry once at a temperature of 80-90 degrees Celsius. The warming up time should be from 1.5 hours, or more precisely: you need to warm up the core of the log to more than 60 degrees Celsius.