Russians' addiction to the bathhouse is one of the features of the national mentality. Many summer residents dream of having a small wooden or stone bathhouse on their plot. High costs, construction time and lack of free space are stopping the owners of small country plots. You can solve the problem if you purchase or construct a barrel sauna yourself. A barrel-shaped building can be placed on any site.

The barrel sauna is a design that is both original and practical. It fits laconically into the landscape and attracts the attention of neighbors and friends with its unusual shape. Such a building has a large number of advantages.

Advantages and disadvantages of a barrel sauna

The advantages of barrel-shaped baths include:

- Interesting, unusual design appearance.

- The ability to quickly prepare the premises for bathing procedures. In summer it takes from 15 to 20 minutes to prepare the steam room, and in winter about an hour. The internal space is heated evenly due to its special spherical shape.

- Economical. To heat a steam room, a few logs are enough.

- Compact sizes. The light weight and dimensions allow the structure to be moved and installed on any flat surface.

- The construction of a barrel-shaped structure is cheaper than the classic version of a stone (brick) bathhouse or log house.

- Construction is being carried out without pouring a capital foundation.

- Thanks to the “thermos” effect, the interior of the structure quickly warms up and retains heat for a long time.

- Easy to maintain and use.

- Speed of construction. Craftsmen install a barrel sauna bought in a store in a few hours.

- Environmental friendliness. Natural materials are used for the construction of the bathhouse.

- Long service life of the building.

There are not many disadvantages to a wooden building. It is necessary to position the barrel so that its bottom is ventilated. Liquid must not accumulate under the floor, as this will lead to rotting and destruction of the wood.

The second disadvantage is the cramped space inside the structure. The maximum possible size of such a structure is 6 meters. A small steam room can accommodate from 2 to 4 people. A small mobile sauna is suitable for small families. In wooded regions, such a building can be erected with your own hands; for residents of other regions, it is easier to order the production and delivery of a barrel from specialists.

The disadvantage of the design is that single-layer bathhouse walls cannot be treated with strong “chemistry”. In addition, it is believed that a structure with thin walls does not retain heat well and is suitable for use only from spring to autumn. This drawback can be easily eliminated if you line the outside walls with thermal insulation and then cover it with decorative materials that imitate wooden boards. Of course, the bathhouse will cost more in this case, but it will be suitable even for use in cold regions in winter.

If you compare the number of pros and cons of installing a barrel bath on your personal plot, it becomes clear that there are many more advantages.

Construction of a barrel sauna

In order to assemble a sauna barrel with your own hands, you do not need too much effort and time. Even a person who has not previously been involved in construction and does not understand this issue can cope with such a task.

The cedar barrel sauna is very easy to assemble due to the fact that each board has special grooves that lock together very conveniently. Collecting such a miracle is the same as putting together a construction set or a mosaic. Another advantage is that the bathhouse can be disassembled and reassembled more than once, and it will not lose its properties, thanks to its increased wear resistance.

If you've never even encountered assembly issues, you won't spend much time figuring out what needs to be done. Assembling the structure is very simple, but it is very important to correctly order all the necessary parts and prepare tools for assembly in order to provide yourself with everything you need. You can assemble such a miracle in just a couple of hours - for this you will just need to assemble all the parts like a construction set and tighten everything with hoops to ensure the strength of the structure. It is important to choose the right parts and within a couple of hours you will have a new barrel sauna in your yard, which will become a real godsend for you.

Kinds

In Russia, original barrel-shaped buildings came into use not so long ago. Such baths are common in Scandinavian countries and Japan. The idea of using barrels for bathing is not new. On the private plots and dachas of Russians you can see several types of barrel-shaped structures:

- Japanese ofuro. It is a barrel that stands on a base and has a bench and a partition inside. The structure can be installed indoors or outdoors. The building does not have its own roof.

The Japanese believe that bathing in ofuro helps bring inner feelings into harmony. The structure is easy to build, but preparation for bath procedures requires more time than warming up a closed steam room.

- Classic Finnish sauna. This type of steam room differs from other bath buildings in the presence of dry steam. To install it, it is necessary to organize a ventilation system. Several benches are installed in the steam room - beds with different heights and a stove. For contrast procedures, it is necessary to equip a shower or a pool with cold water.

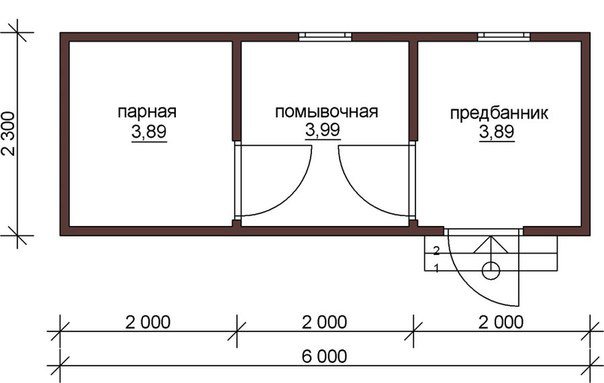

- Russian bath. A steam room and a washing compartment are located inside the structure. Such a bathhouse in a barrel is quickly and easily assembled.

In the steam room there is a bench - a bench, a small stove-heater or an electric heating device. A washing room is required for contrasting water procedures. The boiler (stove) is placed so that the heater is in the steam room and the firebox is in the washing room. For a small room, small heating devices are purchased. A special feature of the Russian bathhouse is the presence of a waste water outlet.

Construction of a barrel bath

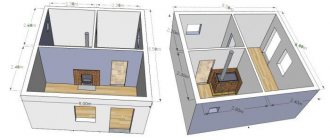

The main distinguishing feature of the barrel sauna is its shape. A cylindrical wooden structure consisting of planks that connect round (sometimes oval) ends. The building is tightened with hoops. The dimensions and internal diameter of the barrel can be any. The capacity of the bath depends on the size.

The diameter of the building most often ranges from 2 to 2.5 m. The length of the barrel varies from 2 to 6 m, but there are also larger structures. The doors to the barrel sauna are made of wood or tempered glass. A stove-stove is placed at the farthest end from the entrance. Tanks and benches are installed along the walls.

A small room can accommodate 1-2 visitors. A larger structure can accommodate a shower and a relaxation area. The zones are separated by wooden partitions.

Communications are connected to the building:

- water pipes;

- gas (for heating);

- sewerage;

- electricity.

The interior of the barrel bathhouse is almost no different from the decoration of a Russian bathhouse. But equipping a barrel is cheaper for its owner, and the structure takes up little space. The Finns were the first to build such baths. In Finland, as in Russia, bath culture is developed. In this country, they approach this issue as practically as possible. The Finns' ability to save and count money led to the emergence of cheap and mobile barrel-shaped saunas.

Barrel baths can be installed vertically and have very small dimensions. Such designs are most often designed for 1 person.

A vertical bath takes up minimal space. Water is poured inside already heated or a steam generator is used.

Characteristics

You need to choose a ready-made barrel bath taking into account the following factors:

- Thickness of boards. To build high-quality barrels, wooden planks with a thickness of 30 to 40 mm are used. The ability of the structure to retain heat depends on this.

- Dimensions of the bath. They must correspond to the number of visitors and free territory on the site.

- Price. The larger the size of the structure, the more expensive its price.

- Layout. The functionality and price of the building depended on the number and location of premises.

- Heating type. The building is equipped with a gas or electric boiler, a stove, a steam generator and other heaters. Each equipment is designed for a specific type of bath.

- Complete set. Along with the barrel, the kit may include additional elements (an extension - an entrance hall, a covered terrace, benches, a table, steps, a barbecue, a stove with a grate).

It is easier for the buyer to buy a standard project and then complete it. There are other characteristics that need to be taken into account when choosing a barrel bath.

Dimensions

Each factory offers customers its own models of barrel baths. The most popular designs among consumers are the following sizes:

- “Mini” with a length of 2 to 2.6 m. The compartment with a steam room takes up from 1.8 to 1.9 m.

- 2-4 people can take water procedures in a miniature bath at the same time.

- “Economy” baths are 2.8 m long.

- “Standard” design with a length of 3 to 3.5 m. Usually the design is divided into a steam room and a dressing room.

- “Premium” or “luxury” have a length of 4 to 6 m. They are large wooden buildings consisting of 3 rooms (steam room, dressing room, wash room).

- “Exclusive” are most often built to order. The length of such products is 6 meters or more.

Forms

There are several options for the shape of a bath in a barrel:

- round;

- shaft (ellipsoid);

- rounded - rectangular design (represents a rectangle with rounded corners).

Materials

The barrel is made of wood. The boards are laid out in one layer. It is important that the type of wood used to build the structure must be resistant to moisture. The best options are oak and cedar barrels. These types of wood are expensive. Construction from resinous conifers will cost less.

Important . In order for the bathhouse to last a long time, the boards must be regularly treated with protective water-repellent compounds.

I’ll tell you how it usually happens – “from project to launch”

- You choose a manufacturer (I’ll write about this at the end of the article), decide on the model and filling, after which it is assembled for some time. Yes, of course, make a partial advance payment.

- Due to its light weight, a powerful foundation is not needed and therefore there will be no large costs for its arrangement. And if seasonal use is expected (spring-autumn), then perhaps everything will be limited to concrete blocks or wooden logs, or even just gravel backfill.

- Then, you need to take care of the foundation. Typically, the manufacturing company issues standard designs, but in any case they must take into account the characteristics of your site. I mean the topography and soil characteristics (freezing depth, presence of groundwater, etc.). Therefore, the standard design may be changed.

- When ready (and this can be from a week to a month), you are notified, and on the appointed day a car arrives, on the loading platform of which your bathhouse will be. The “kit” comes with a truck crane.

Of course, you should arrange for the equipment to arrive at the unloading site. A very important point, because if it is impossible, the responsibility is yours. Take care in advance. However, this is probably stated in the terms of the contract. A team of workers will install the finished bathhouse trailer on the foundation. All. All that remains is to connect the communications and the house will come to life.

Perhaps the manufacturer will offer you a turnkey service. That is, it will itself build a foundation, install a bathhouse and connect communications (which must be brought to the “landing” site in advance). Think about it - it could be profitable. In addition, you will receive a guarantee not only for the house with the filling, but also for everything else. Although you will also have to overpay.

How to make a barrel sauna with your own hands?

There are a large number of models of ready-made baths made in the shape of a barrel on sale. Such designs are relatively inexpensive. Despite this, there are people who decide to build such a structure with their own hands.

Before you start building a bathhouse, you need to create a drawing, prepare the starting material, and choose a place to install the structure. The bathhouse is built where it will remain permanently. The work consists of several stages:

- Measurements and drawing creation.

- Preparing the installation site. A foundation for a small barrel-shaped bathhouse is not needed. To install the structure, you only need to create a flat, solid platform. Any paved or concrete-filled area of the yard will do. If there is no such territory, you will have to choose a place in the garden, which is then compacted and covered with crushed stone or gravel.

For a large bathhouse, a foundation is created. First, mark out the area (it is equal to the dimensions of the barrel plus 50 cm), remove the soil to a depth of 20 cm.

The pit is filled with sand and gravel, and metal reinforcement is laid. After this, formwork is constructed and the lower layers are poured with concrete.

The foundation will harden completely in about 3 weeks. In parallel with this work, a drainage hole is dug, which is lined with bricks and covered with a concrete lid with a hatch. The spillway can be connected to an existing sewer system.

The site is built with a slight slope to effectively drain water. If you have available funds, you can purchase a septic tank. A pipe is lowered into the waste pit, its second end must be connected to the drain system of the barrel.

- Construction of a stand for a bathhouse. For supports, use logs of equal thickness or edged boards.

The number of beams depends on the length of the bath. It is advisable that they stand at a distance of no more than 1 m from each other.

If boards are used, they are also installed in increments of 100 cm. Round cutouts are cut into the supports, the size of which corresponds to the diameter of the barrel. The boards are connected to each other using crossbars, corners and fasteners. The structure must be stable and support the weight of the entire structure.

Metal corners add rigidity to the structure. These fasteners are fixed at all joints of the supports with the lower transverse boards without exception.

The first longitudinal crossbar is secured in the center of the lower support board with self-tapping screws. To calculate the number of longitudinal parts, the circumference of the barrel is divided by the width of the board. To create a stand, take a 50 mm board, and for longitudinal ones, material 40 mm thick is suitable.

After the first longitudinal board, the rest are attached. Installation is carried out using the groove connection method.

Before starting work, the boards are sanded and treated with antifungal compounds. Installation of end walls and partitions. These parts are made from square panels. Circles of the required size are marked on the workpiece and then these elements are cut out with an electric jigsaw.

Doorways and windows are marked on the circles. The holes of the desired shape and size are again cut out with a jigsaw. A door is placed on the front of the structure, opposite it there are one or two windows.

Vertical walls and partitions are installed using corners and other fasteners. At this stage of construction they must stand stably without side walls.

- Erection of side walls and roof construction. The installation of the structure frame ends after attaching the longitudinal boards in a circle.

Steel clamps (hoops) are stretched around the barrel. The metal strips are bolted to the wooden frame. The screed gives the structure strength and reduces the gaps between the boards. The roof is covered with tiles or metal plates.

- Installation of doors and windows.

- Processing of joints. All cracks are caulked and filled with sealant.

- Communications (electricity, water) into the structure

- Arrangement of interior premises. A drain hole is made in the floor through which a pipe or hose is led out.

- Wooden gratings are installed on the floors. They install the stove and benches.

It is better to entrust the installation of heating equipment, electrical networks, plumbing, and ventilation to specialists. They install the grate around the stove and decorative elements independently, without the help of a specialist.

For a bath, you can purchase a wood-burning or electric stove (boiler). The heating device must be small in size. The floors and walls around the stove are lined with refractory materials, metal plates, and tiles.

Wooden elements are treated with water-repellent impregnations. This will protect the structure from deformation and rotting.

If the bathhouse will be used in cold regions, the walls can be lined with heat-insulating materials on the outside. To ensure that the structure does not lose its visual appeal, cladding that imitates natural wood is used.

Building a bathhouse is not an easy task. Before taking on this task, you need to make a drawing and leave an estimate. Write out a list of work that you can do yourself, and those that are best entrusted to specialists.

Building materials in the retail chain are more expensive than they cost when purchased in bulk to companies that manufacture mobile wooden bathhouses in barrels. When calculating costs, it may turn out that self-construction of the structure will cost more than the finished product.

About security

Manufacturers are required to certify standard designs of transportable bathhouses, but I strongly recommend requesting a certificate. You never know...

Let me explain for those who are not in the know. If the bathhouse is certified, it means that all the requirements related to the standards for its safe operation have been met. In particular, insulation of the structure, protection of electrical wiring, calculation of ventilation.

It is mandatory to carry out priming of the material from excess moisture, hydro and vapor barrier, impregnation with antiseptics, protection from biological activity (wood insects, fungus, mold), increasing fire resistance (treating wood with special compounds - fire retardants) and so on. In general, everything is in accordance with the requirements of regulatory documents for such baths.

Of course, if you wish, you can build it with your own hands, using decommissioned kungs, construction trailers on wheels, and even large-volume tanks (you know the kind, barrel saunas) as a basis for the structure. Just, first, ask about the price of ready-made ones. Perhaps it will be inexpensive for you, and you will save time.

Photos of barrel baths

Examples of structures built by amateur craftsmen are presented in the photo. You can use any of these ideas to create your own original project.

Bathhouses - barrels laconically fit into the village landscape, wooden buildings look good in any garden plot. If you use a little imagination, you can transform a finished structure purchased in a store.