When cutting a log house using the “into the bowl” method, there is no such question as finishing the corners - the corners when cutting “into the cup” (in the oblo) are intertwined with a braid and are initially aesthetic, but when cutting the log house using the “into the paw” (dovetail) method, the corners of the log house are like external , and the internal ones look less aesthetically pleasing - this is due to the cutting method, so there is a need to refine the corners when cutting the log house “in the paw”.

The corners of the frame must be trimmed after the frame shrinks. An example of finishing the internal corner of a log house “in the paw” can be seen in the photo.

The cost of finishing the corners of a log house “in the paw” is from 400 rubles. for 1 m.p.

Articles

Our works

Bathhouse made of timber 5.5x5.5, Priozersk, Leningrad region. Season 2020

Log house 9x8+2, Mga village, Leningrad region. Season 2020

Log house 8x10, Lzi village, Leningrad region. Season 2020

After the log house or bathhouse has dried and sat down, they begin interior and exterior decoration. In the process of finishing log houses, cut into paws, there is a need to seal the internal and external corners to give them a more beautiful appearance, but before sewing the corners must be insulated. This must be done because in the process of shrinking and drying out the log house, gaps will inevitably appear in the crown grooves, as a result of which the corners will be blown through and there will be air through them, and in winter the corners may freeze and heat will escape from the house.

The first stage of insulating the corners of the log house

Insulation of corners must begin with caulking. Caulking means driving insulation material into the inter-crown grooves; for this you will need a hammer and a special chisel with a width of at least 5 cm and a thickness of no more than 5 mm. For caulking corners, several types of materials can be used, both traditional and recently available on the market.

- Moss. Perhaps the oldest material for insulating wooden houses, unlike tow, birds do not pull it out and it has antiseptic properties, it does not rot and fungi do not form in it. In addition, moss is very durable; there have been cases that when dismantling wooden houses that were cut down at least 70 years ago, the moss between the crowns did not rot or turn black, and it could be used to re-insulate a new house. Moss is able to absorb moisture and dry quickly; it does not contain any components hazardous to health. In addition, moss does not cost much, and if desired, you can even collect it in the forest yourself.

- Linen or jute. High-quality flax or jute, like moss, dries quickly when absorbing moisture and prevents harmful fungi from spreading. It is easy to use, comes most often in the form of strips, unlike moss, it does not crumble, and is excellent for assembling and insulating log houses.

- Lnovatin. Modern domestic thermal insulation material. It is made from short flax fibers, flax fiber tows and jute. Just like jute, it comes in the form of strips of different widths and thicknesses. Quickly releases moisture, is not susceptible to rotting and fungus, and is not affected by moths.

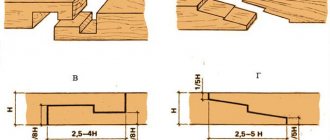

How and why a longitudinal groove is cut out

All logs of the log house must have longitudinal grooves corresponding to the ridges of the bottom of the logs that will be laid on top. These grooves are needed to preserve heat in the log house, and to prevent the log house from being blown by the wind. According to GOST, longitudinal grooves must have a width no less than 0.5 of the log diameter.

The choice of the width of the longitudinal groove depends on the minimum air temperatures and is assigned:

- At - 40⁰С from 140 mm or more

- At - 30⁰С from 120 mm or more

- At - 20⁰С from 100 mm or more

The triangle groove shape is easy to manufacture, but does not provide a tight and durable joint. It is almost impossible to densely fill a triangular cavity with tow or jute, and during operation condensation accumulates there, insects, mold and mildew grow there. Open wood capillaries take water from the insulation when it soaks. Due to excess moisture, logs have low resistance to rotting. The thermal protection of such a log house is unimportant. Another disadvantage is constructive. The greatest load on the log falls precisely on the top of the groove triangle, in the place where the section is weakened, the groove can crack and open, and cracks will appear along the inter-crown joints.

The only advantage of the “triangular cut” is speed. It is only suitable for log houses that will not be heated, for various warehouses and outbuildings. For a residential log house, such a longitudinal groove is not suitable; it is considered rough and cold.

The better the groove follows the shape of the ridge of the log laid in the bottom row, the more difficult it is to fit, and the warmer and denser it is.

The second stage of insulating the corners of the log house in the paw

For better insulation of the log house, the corners are additionally insulated and sewn up outside and inside the log house. Before starting external insulation, the corner of the log house is leveled using a chainsaw. After this, the corner is treated with protective antiseptics to protect against fungus and mold, as well as for fire protection. After this, four vertical guide posts are mounted on the corner of the log house; to avoid hanging corners, the guides must be mounted on sliding fasteners. Galvanized metal profiles or dry wooden blocks treated with antiseptics are used as guides. After this, linen or jute insulation is placed in the cavity between the guides along the entire length of the corner, after which a windproof membrane is mounted on the corner, all joints of the windbreak and the frame are carefully glued using double-sided adhesive tape.

After insulation, the outer corners are sewn up. Most often, imitation timber and logs, as well as dry planed boards, are used to fill corners; less often, unplaned boards, metal or vinyl siding are used.

Our company carries out the following types of work on finishing corners in log houses and bathhouses:

- Caulking of corners in log houses cut into bowls and paws, in log houses made of timber

- Insulation of corners

- Sealing and painting of external and internal corners in log houses with boards, clapboards, imitation timber and logs

How to properly close the corners of a log house when insulating the log house in a bowl or in a paw? Improper execution of this stage of work will lead to a lack of living comfort (drafts, heat loss, dampness, etc.).

Caulk of a log house with moss

After the crown logs are finally adjusted, they begin laying the inter-crown insulation. The moss is laid out across the logs with a layer thickness of 15-20 mm, pressing slightly, but not tamping. Lay out the moss to a width greater than the width of the longitudinal groove of the upper logs, by 100 mm. Moss is placed in the bowl and around the bowl in the same layer, with a protrusion of 50 mm beyond the contour of the bowl.

The traditional and correct technology is laying the log house “on moss”. Or on tow, in case of using tow. But assembling log houses without inter-crown seals, in a hurry, and then driving the seal between the crowns is not a technology. Such log houses do not last long; beetles and company settle in the cavities between the logs, and fungus and mold grow. This is because it is simply impossible to hammer a sealant from the outside into a finished frame; cavities always remain. Sealants used in external seams save the situation for a short time. In a short time, such log houses become cold.

After laying the compactor onto the log, lay the top crown log on top, being careful not to move the moss. The stacked logs are tapped with a wooden “woman”.

After laying the logs, caulk the bowls, tucking the protruding fibers between the log and the bowl. The tool for this operation is called a caulk, and the caulk is tapped with a mallet or hammer.

Dry moss is placed in the crowns, and the frame is moistened with caulk. If moss is dried and then soaked, its strength is much greater than that of fresh moss.

They caulk the log house in two passes. First, immediately after assembly, filling the gaps between the crowns with a sealant as tightly as possible. Caulk until the moss begins to spring under the blows of the mallet on the caulk.

The crowns run along the entire contour, first from the outside and then from the inside. This work is not considered difficult, rather long and monotonous. The crowns are caulked from bottom to top, one at a time. Incorrect caulking can cause the frame to warp.

The second pass is made after the frame shrinks, which takes about a year. The second caulk is made in exactly the same way as the first.

“A paw is the end of a log that has been processed into five edges. or your wife when you need to take time off for an overnight fishing trip” (author)

Hello to all blog visitors!

A log house in the paw is also called a “clean corner” and “a log house with corners without residues.” People quite aptly give images of technology in the corners of a house or a bathhouse chopped with an ax. It is the corners that are the most difficult process, requiring careful adjustment.

Even small deviations of the cutting in the paw create consequences, the most serious of which are the blowing of the corners and the violation of their verticality (i.e. the bathhouse will be lopsided). We will leave detailed questions about how to cut a log house to people who are professionally trained, and the topic of today’s conversation is insulating the corners of a log house in the paw.

From this article you will learn:

Features of closing and insulating corners for different types of felling

The choice of material for insulating corners chopped into a bowl depends on the type of wood used in construction. To seal timber structures, the following are used: natural moss, jute fabric, flax batting, etc. It is important to use the same material that is laid on the crowns. You should not use different insulation materials, so as not to cause defects due to the difference in the thickness of the sealant. A log house made of logs (untreated or rounded) must be insulated with jute or linen rope, the twisted structure of which will ensure complete elimination of cracks.

Constructing a log house using the “in-the-cup” method is a labor-intensive process that requires more building material than the “in-the-paw” option. The Canadian type is now popular, characterized by the presence of a fat-tail protrusion in the recess and a trapezoidal shape. During the shrinkage process, the logs form super-strong joints with the insulation. As a result, the penetration of cold and drafts into the room is completely eliminated. This construction option is much more expensive than a simple (rounded) bowl. Log houses with crowns in a bowl or Russian corner are not covered with external finishing; in the area of the ends the wood breathes and therefore lasts longer. To seal, use caulking of the corners with a rope, which is pushed into the gaps using special tools. The material is hammered in using a mallet, which is used to hit the caulking blade. During work, you need to pay special attention to the joints of the corners with the ceiling and floor. Especially below, where sources of dampness are located. If a wild log house is being built, it must also be caulked.

Insulation of a log house in the paw

Log cuts that form a paw lock or a German corner are more susceptible to rapid rotting and environmental influences. Therefore, it is more difficult to properly insulate corners. 1. The process should be carried out more carefully than for the bowl. 2. The cracks are sealed at the time of construction of the log house, the corners are sealed more tightly. 3. For a beginner, it is better to assemble crowns using a stencil to draw each end of a beam or log. 4. An incorrectly supplied element is immediately replaced. To insulate the log house, jute fabric, folded several times, is used in the paw. Birds love to take away the tow, and the moss turns into dust over time. Features of closing and insulating corners for different types of felling depend on the work area: inside or outside. When constructing a permanent house, it is necessary to use these two options. You need to be more attentive to external elements.

Layered insulation is used if the log house is intended for exterior decoration. Caulk and sealant are a universal combination, most suitable for rounded logs.

Insulation for external cladding

In modern construction, an interesting method of insulating a log or timber frame is used if the external cladding of the building is planned. You need to cover the corner with a foil membrane or secure it with a furniture stapler. When externally insulating the outer surface of a house, before finishing with siding, the following is used: 1. Basalt insulation. 2. Foamed polyethylene. 3. Fiberglass materials. 4. Foam plastic. 5. Extruded polystyrene foam. Non-flammable insulation and metal siding increase the fire safety of a wooden house. Before the outer cladding, sheathing, insulation and a hydro-windproof membrane are attached to the surface of the log house. This layer-by-layer structure is called a thermal insulation cake.

Finishing the internal corners of the log house

Grinding the corners of the frame outside and inside is always carried out before starting other work in order to prevent freezing of the wood, interaction with moisture and rotting. During the treatment, the remaining bark is removed and the cracks are filled. The equipment used is a machine with petal attachments and a grinder. The process begins from the edges, moving towards the joints. Personal protective equipment is required due to the large amount of dust. After completing the work, the log house is left for a day to dry. A simple way to finish the internal corners of a log house is to install a pair of vertical edged polished boards. They must be tightly closed to avoid a gap, resulting in an even vertical angle. Less commonly, the board is installed at an angle of 45° to each wall. Internal surfaces are treated in different ways, for example, lining, plastering, plasterboard. Mineral wool, polystyrene foam, and isoplat (pressed flax fiber) are used as insulation materials.

What happens if you don't close the corners

If you ignore the stage of insulating the corners of the log house, in addition to the lack of comfort during your stay, there is guaranteed to be a distortion of the shape of the structure, which will become askew over time, dampness and elements of rotting wood will appear. What happens if you don't close the corners from the outside? External insulation allows you to more effectively maintain comfort in the house compared to internal insulation, and therefore is more important. If you cut a corner of logs or beams without sufficient experience, then there is a high probability of defects appearing after construction, in particular large gaps during shrinkage. The situation is corrected with the help of wedges. They are cut from the same type of wood as the log house. Mistakes when sealing corners will also lead to serious problems. For external insulation, you cannot use polyurethane foam, which will accumulate moisture over time and cause dampness in the wood. When choosing sealants, you should not use silicone or acrylic types due to the high likelihood of peeling or cracking. You should pay close attention to the internal and especially external corners, since they become the paths for cold penetration if the insulation is improper.

Our website presents a number of log house projects, for example: https://www.domastroim.ru/category/proekty-domov/proekty-srubov-domov-ploshhadyu-svyshe-200-kv-m/ Or you can see all prices for log houses . You can calculate the house or bathhouse you need with maximum accuracy using our log house cost calculator. To order and buy a log house, call:

- Vologda

- Moscow,

Modern insulation materials

I’ll say right away that materials with a closed porous structure (foam plastic, polystyrene foam, penoplex, etc.), sprayed polyurethane foams (including polyurethane foam), synthetic sealants (acrylic, silicone, etc.), foamed polyurethane foams (such as foam rubber) – completely unsuitable for insulating log corners. Why? Because they are absolute vapor barriers. Moisture emanating from a house or bathhouse, accumulating in the thickness of the insulation, causes the seam itself to freeze.

Or another case. There is a so-called “warm seam” offered by some sellers as a reliable option. However, if we follow the technology of its installation, we will end up with hermetically sealed seams and the absence of natural ventilation. Inside the heat-insulating tape, moisture vapor from inside the house collects, which means you can expect condensation to appear at the joints and accelerated rotting of the corners. This method is good for insulating double-glazed windows in a concrete house, but not for the corner of a log house.

But practical Finns use a special type of tow, made like double-sided tape. Tow can “play” with compression and expansion in the range from 5 to 15 mm. It allows vapor to pass through, but does not absorb moisture. And there is no need to re-caulk.

There are also well-proven new products made on the basis of jute (ThermoJUTE) and flax (ThermoFLEN). These are specially developed products for insulating wooden buildings and the reviews about them are quite good.

One of the radical ways. The corner is completely covered with foil insulation (foil facing out), or nailed with a furniture stapler. The top is covered with wooden paneling for decoration. Helps. But it looks alien and there is no vapor barrier.

Perhaps that's all. I hope the information will be of benefit to someone.

An anecdote from everyday life: “A wife is washing dishes, seeing a leaking faucet in the kitchen, calls her husband. - Pashka, come here, change the gasket for me! The husband mutters fiercely - well, you're completely lazy. »

Good luck and dry corners to your log houses! Bye! Bye!

Wisdom Quote: He who laughs is not angry, because to laugh means to forgive.

Please tell me what options exist for interior finishing of corners in a log house assembled into a claw. Thank you.

Tanya, Samara.

Hello, Tatyana from Samara!

Regarding the options for finishing the corners of a log house assembled into a paw, I can say the following.

Option one

Everything is left as is and nothing is done. What you can see in numerous movies when they show the interior of log houses. They don’t show it on purpose, but just like that, in passing.

Option two

Since in the classic cutting of logs into a paw on the inner and outer sides of the wall, flat surfaces are made vertically with an indentation from the joint of approximately the same amount, it is possible to install two vertical edged boards. The boards are sanded. They are installed tightly to each other without any gap between them and form something like a vertical angle.

In addition, the classic paw connection is complemented by a hidden root tenon. Its length is about one third the length or width of the paw. It is located close to the inner corner. And it serves to ensure that there is no displacement of the logs in the paw.

Laying and further caulking of tow joints is mandatory, and if the tow is visible, it is not only tapped (which is done at least twice), but is often made in the form of an applied pigtail. Or they even stuff such a rope. It looks beautiful.

Much less often, corners are covered with one vertical board, which is installed at an angle of 45 degrees with respect to both walls. This is already the third option.

I haven't come across any other options yet.

Construction in Moscow and Moscow region

Wide range of construction services. Foundation, walls, ceilings, roofing, turnkey!

Other questions on the topic of log houses:

Replacing logs in log houses

About caulking log houses

All about log houses

Construction in Moscow and Moscow region

Wide range of construction services. Foundation, walls, ceilings, roofing, turnkey!

Construction in Moscow and Moscow region

Wide range of construction services. Foundation, walls, ceilings, roofing, turnkey!

Construction in Moscow and Moscow region

Wide range of construction services. Foundation, walls, ceilings, roofing, turnkey!

Log houses and their maintenance

Semenych (author of materials)

Our site is regularly updated with interesting and unique materials and articles on the topics of lumber, building materials and works, the author's opinion and knowledge of a real coven with more than 15 years of experience are provided. There is a section - funny stories of shabashniks. If you would like to receive information about this, subscribe to our website's newsletter. We guarantee that your address will not be shared with third parties.