Glass-magnesite sheet, the application of which, the disadvantages of which will be presented in the article, is a modern building material with excellent quality characteristics. It has the widest scope of application in interior and exterior finishing work. A number of builders believe that these sheets, also called magnetite, represent a worthy alternative to drywall. That is why you may be wondering what to choose - glass-magnesite sheet (GML) or plasterboard (gypsum plasterboard).

The first material is superior to the second in a number of indicators. Home craftsmen and representatives of professional companies most often use standard materials, which is due to the lack of information about new solutions. However, magnetite allows you to save money and time when carrying out work.

general description

Glass-magnesite sheet, the application of which will be described below, has an interesting structure. It contains magnesium oxide, perlite, magnesium chloride, as well as fine wood shavings. Fiberglass mesh is also used in the production process. Different manufacturers have different percentages of ingredients, this is due to different classes of material. Among them are “Premium”, “Standard”, “Economy class”. If you want to use more durable sheets, then you should prefer those that have a higher content of magnesium oxide. As a rule, glass magnesite sheet, the application of which the disadvantages are described in the article, contains MgO in an amount of 40%, this refers to a premium product, while MgCl2 is added in an amount of 35%.

Asbestos substitutes

Asbestos papers and cardboards are used as sealing and filter materials for cleaning liquid media. High surface activity and small sizes of needle-shaped crystals (and, accordingly, small effective pore sizes) allow high-quality purification from impurities. However, currently non-woven materials based on ultra-thin chemical fibers are used for this purpose, which have largely replaced asbestos.

Asbestos fabrics have served for many years as thermal insulation materials, material for sewing protective clothing for firefighters, capes and other technical needs. However, they are inconvenient to use - they wear out quickly. Today, protective equipment (primarily suits) based on multilayer bags, including polymer heat-resistant fabrics with heat-protective layers, aluminized on the outside to achieve high reflectivity, are widely used for these purposes. Suits for working in extreme conditions when exposed to open fire today are complex designs that allow long-term work in contact with an open flame. Thus, the use of asbestos for these purposes is already an anachronism.

Sealing cords for shafts and other moving parts have traditionally been made from asbestos in combination with other types of fibers. Today, they have been successfully and more efficiently replaced by textile structures made of carbon and fluorine fibers, which are more reliable and durable in chemically aggressive environments.

Asboplasty. In structural asbestos plastics, asbestos fibers (asbestos fiber), papers (asbogetinax) and fabrics (asbestos textolite) are used as a reinforcing component. The binders in asbestos plastics are usually thermosetting resins - phenolic, melamine-formaldehyde, etc., as well as thermoplastics.

Various parts or products are made from thermosetting asbestos plastics, including electrical insulating parts and products for low-voltage equipment, friction products (brake linings and pads), parts of chemical equipment (for example, pump rotors) and others. Asbestos fiber concrete (faolite) is used for lining equipment. Asbestos textiles are used mainly in electrical products. These materials are currently losing their importance and are being replaced by glass or carbon fiber reinforced plastics. A widely known material is sheet paronite based on asbestos fibers, other fillers and rubbers, used for sealing gaskets. Today it is successfully replaced by materials containing carbon and aluminum oxide fibers.

Friction materials are traditionally made on the basis of asbestos using heat-resistant binders - phenolic, modified phenolic containing rubber and other ingredients.

Friction materials are subject to very high demands, and today they are not easy to select. They must have a stable coefficient of friction (from 0.25 to 0.5), high wear resistance, and heat resistance. The counterbody should have minimal wear during friction. The temperature on the friction surface reaches 400–500°C, and sometimes up to 600°C, and in the bulk of the material 200–250°C.

Today, the manufacture of brake linings and pads, discs and clutches for ground transport, pressing equipment, sewing machines and other devices and mechanisms that require quick and reliable stopping or smooth start-up is carried out using carbon, aramid, glass, and basalt high-modulus fibers . Thus, the replacement of asbestos in friction materials has now been resolved.

Asbestos-cement products and pipes made from it are important widely used materials in construction, electrical engineering and some other fields. Today, its replacement with cheaper materials is achieved using glass and basalt fibers. The finished material and products are safe. The cheapness and availability of asbestos cement makes it difficult to replace. However, for example, in electrical engineering it is successfully replaced by fiberglass and other plastics.

We should once again dwell on the problem of asbestos toxicity. Asbestos itself, already included in various materials, does not have harmful properties.

However, asbestos dust, as already mentioned, is very dangerous to human health. It is released in large quantities during the extraction and sorting of asbestos, its processing and wear of friction devices. That is why the use of asbestos is prohibited by law in many countries, and in Ukraine and the CIS countries work is systematically carried out to replace asbestos. An important problem is the replacement of asbestos-containing friction linings. Forming asbestos dust when worn, such materials are harmful to people. Therefore, for example, the import of cars with asbestos-based friction parts is prohibited in a number of countries. The same applies to the use of friction materials in industrial equipment.

An important environmental problem is the use of recycled, waste asbestos-containing materials. Shredding them for reuse, releasing dust, can also be hazardous to people, although in lump form there is no noticeable danger.

So, today the problem of replacing asbestos with other types of fibrous materials has been solved. The point is to minimize and then completely eliminate the use of asbestos-containing materials, replacing them with more advanced ones that are safer for people.

allmax.com.ua

Features of the structure

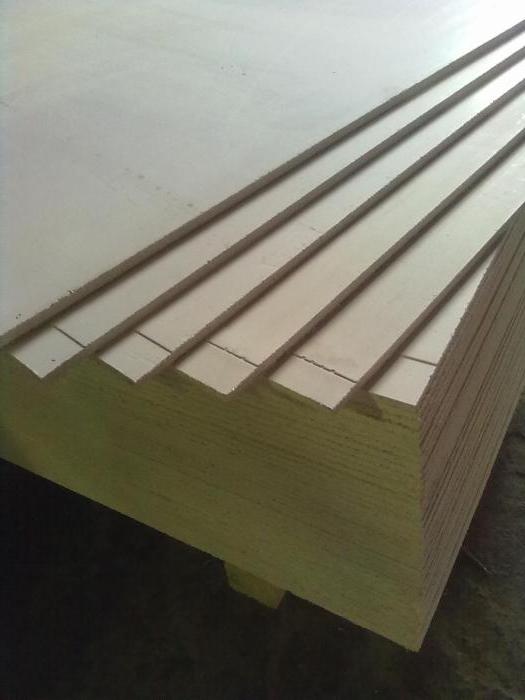

The material is made in the form of sheets, the thickness of which can vary from 4 to 12 millimeters. The most common dimensions of the canvas are 2440x1220 millimeters. The outer side of the canvas has a smooth surface; it does not require additional processing; wallpaper can be immediately glued to such a base, and then paint can be applied. As for the side, it is rougher because it is not sanded. Installation of sheets can be carried out by either side. Most often, LSU is installed with the back side facing outward for treatment with plaster, which is due to its more impressive adhesion properties.

Area of use

If you are interested in FMS (glass-magnesium sheets), what it is, where and how to use it, you definitely need to find out before purchasing the product. The described material has a wide range of applications; it is used for finishing residential, industrial and public buildings. In private construction, LSUs are used when it is necessary to install arches, walls, partitions, and suspended ceilings. This material can be used for finishing slopes, communication shafts, and installing ceilings. It is convenient to use sheets as permanent formwork for pouring lightweight concrete. Using glass magnesite, the external walls of houses are finished, followed by the application of finishing materials.

Where is this material used?

Material suitable for insulation:

- Doors.

- Windows

- Stan.

- Ceilings.

- Polov.

- Internal walls of baths and saunas.

- Chimneys.

- Ventilation shafts and channels.

- Gypsum fiber boards and plasterboard.

- Heating elements in boilers and boiler houses.

- Pipelines.

- Industrial equipment and instruments.

- Frying cabinets.

Main advantages

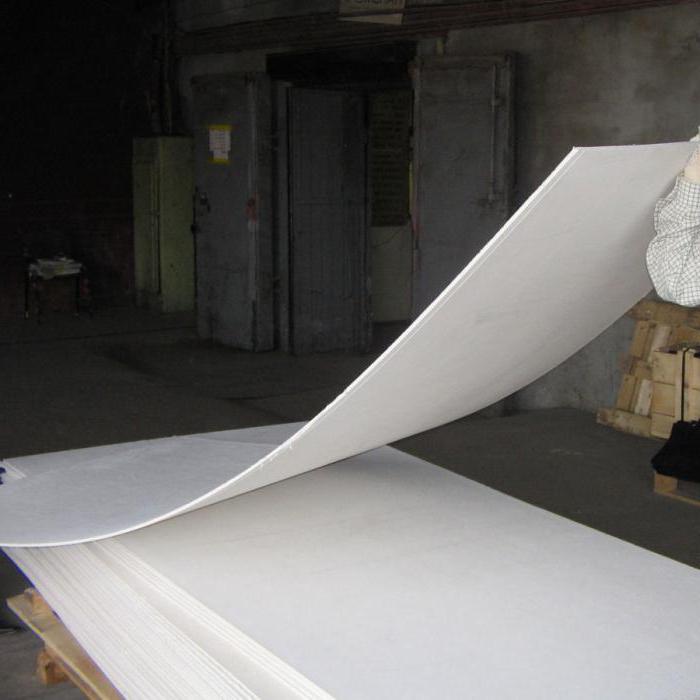

If you are interested in LSU (magnesite board), you should know its composition, advantages and disadvantages even before starting work. Among the advantages are moisture resistance, low weight, flexibility, resistance to biological influences, as well as a wide range of applications. The sheets cope excellently with the effects of chemicals on their surface. Consumers also choose this material for the reason that it is environmentally friendly, frost-resistant, long-lasting, durable and fire safe. In the latter case, glass-magnesite sheets are superior to similar materials. The canvas does not burn even at a temperature of 1200 degrees. In terms of flammability, it can be classified as the highest class A. This includes materials such as metal, stone and concrete.

How to replace asbestos

Asbestos can be replaced:

| Analogs | Description |

| Asbestos fabric | It is woven from viscose, glass fiber, asbestos yarn. This is an ideal option for thermal insulation. This fabric is used for clothing for employees of production workshops working in high temperatures, and for firefighters. Asbestos fabric is an excellent way to insulate a stove or other heating appliances. The fabric will be very effective in extinguishing fires and substances that cannot burn without oxygen. This is a strong, durable, wear-resistant fabric that can protect well from fire without losing its characteristics at high temperatures. |

| Foam glass | It is a combination of two substances - fragile glass and weightless foam. The material is different:

This material loses the classic transparency of glass, but acquires good acoustic and thermal insulation qualities. It is so hard that you can drive a truck on it. It is often used for thermal insulation of load-bearing walls, pipelines, and basements. Despite its high rigidity, foam glass is easy to process. |

| Roll insulation | One of the most common and affordable insulation materials. Its base is mineral wool. Roll insulation comes in the form of:

Each insulation has its own characteristics and is an improved version of mineral wool. Glass wool is quite heat resistant, it can withstand temperatures up to 450 degrees. Basalt wool can withstand thermometer readings up to 700 degrees. Slag wool is less resistant to heat and can withstand up to 300 degrees Celsius. |

Asbestos is widely used for insulation of various structures. However, it is harmful to health, so people often wonder what can replace asbestos.

Today, several common materials are used for insulation, which are practically not inferior to asbestos in their characteristics, sometimes they are even better.

Asbestos fabric

This material is a safer option than regular asbestos. Only asbestos dust, which penetrates into the lungs and causes various diseases, can have a negative effect on the body. Therefore, when working with such fabrics, you need to adhere to safety precautions, otherwise find another material.

To reduce the negative impact of the fabric, it can be painted or covered with film. It is also best not to place asbestos fabric in areas with good air circulation. The main advantage of this material is that it is able to retain all its characteristics even at the highest temperatures.

Foam glass

The material has many advantages over its analogues. The only disadvantages include high cost and low impact strength. However, these disadvantages are not critical and do not outweigh the advantages.

Foam glass can often be seen as backfill in wall cavities or as an insulating additive to concrete.

It is also used in industrial refrigerators and various equipment that operate at high temperatures.

Roll insulation

When using roll insulation based on mineral wool, it is important to consider the surface and purpose of the material. Some options are best used for wood, others for brick or concrete.

It is also important to take into account the thickness of the base, temperature and weather conditions, especially if the insulation is external. Overall, this is a quality option with a lot of advantages.

There are many options for replacing asbestos. However, it is better to choose only proven, high-quality analogues. When choosing insulation, take into account its characteristics and the possibility of using it in certain conditions and the result will definitely please you.

chem-zamenit.ru

What positive features are still worth paying attention to?

Glass-magnesium sheet (GFS), the application of which the characteristics are mentioned in the article, does not delaminate, does not swell or deform, which is true when exposed to moisture for a sufficiently long time. The material perfectly withstands conditions with high humidity, which indicates the possibility of using sheets in baths, saunas, swimming pools, as well as in basements.

For use in conditions with high humidity levels, another important characteristic is biostability. The surface of the canvas is resistant to fungi, mold, insects and bacteria. Acids and caustic alkalis do not harm LSU. You can count on the high strength of glass magnesite, which reaches 16 MPa in bending. It is convenient to work with sheets, as they are easy to cut and do not crumble, nor do they crack.

Fixation can be done using nails, self-tapping screws, or using a pneumatic gun. The canvases can be drilled. If you are interested in glass-magnesium sheets, the pros and cons of the drywall analogue are definitely worth considering. Among the positive features of the described material, one can also highlight its very insignificant weight, which is 40% less than gypsum board.

Frost resistance and strength

If you need a material that has a high frost resistance, then SML just meets these requirements. Its frost resistance is F50. The loss of mechanical strength is no more than 3.5%. During the production process, fiberglass is used, which performs reinforcing functions. This provides excellent flexibility and protects against breakage during transportation and installation work.

Quality of durability and environmental friendliness

Manufacturers promise that the LSU will last for 15 years or more. The final period of life will depend on the correct installation, as well as the characteristics of operation. When using, you do not have to worry about the fact that the canvas can have a negative impact on human health. This is explained by the fact that the sheets do not contain harmful ingredients such as formaldehyde, asbestos, phenol, etc. The material is not capable of causing allergic reactions, therefore it is classified as an ecological product that can be used even in medical and children's institutions.

What can replace asbestos?

As I understand it, you want to replace asbestos-cement facade slabs with something similar in characteristics.

There are many options here, for example, not bad, fiber cement boards for finishing facades.

An absolutely environmentally friendly material, consisting of 90% cement and sand, the remaining 10% fiber (reinforcing material).

These slabs can be produced in various versions, that is, they look like something (for example, imitation stone, brick) or simply smooth.

The material not only does not support combustion, but is also a barrier to fire (like asbestos boards).

Thanks to the fiber, the slabs are durable and can withstand significant mechanical loads.

They are not afraid of temperature changes, UV radiation, and so on, that is, the properties are similar to asbestos boards, but at the same time environmental friendliness is at a different level.

The slabs do not rot, are not subject to corrosion, and are water resistant.

The price is quite affordable.

The choice of colors is simply huge.

www.remotvet.ru

Cons of LSU

If you decide to use glass-magnesite sheet, the application and disadvantages of this material are also important to find out. Among the latter, some features of low-quality glass magnesite can be highlighted. When wet, it can release salt, which can cause metal corrosion. Low-class material can be used exclusively for interior finishing work, which presupposes the absence of high humidity and sudden temperature changes. One cannot help but pay attention to the difference in quality depending on the class. When comparing the Premium and Economy lines, the former has a more impressive magnesium oxide content. Among other things, this top-class product is made using high-quality fiberglass mesh, which has smaller cells. This material has a denser structure and improved fire resistance and frost resistance.

Fastening basalt cardboard

Please note that the foil cardboard must be mounted so that the reflective layer is directed inside the room. This is the only way the foil will be useful. The foil itself protects the living space from radiation. Therefore, foil cardboard is often used in nuclear power plants. Before laying the walls do not need to be treated with chemical mixtures. Thanks to this, foil cardboard is a completely pure insulation material.

Most often, basalt cardboard is attached to liquid nails, or using a regular stapler. Assembly adhesive is used less often. However, it is more reliable, so we recommend attaching the cardboard with glue.