Until recently, few people were concerned about the issue of insulating floors in bathhouses. They were almost all constructed the same way: a flat concrete surface with a slope towards the water drainage point. Wooden gratings were laid on top. The difference in temperature between the floor and the ceiling was enormous. The main reason for not insulating the floors was the lack of thermal insulation materials.

A well-insulated Russian bath heats up quickly , the temperature in it remains stable during washing, and the heat is retained until the next day at any time of the year.

With the help of modern materials, it is possible to achieve high thermal insulation of a bathhouse without the risk of damage to wooden structures.

The need for insulation

As hot air rises, the floor remains cold

Despite the high temperatures in the bathhouse, the floor remains cold without high-quality insulation. Without good thermal insulation, it will take longer to heat the room, and fuel costs will also increase. The temperature will drop faster.

A sharp temperature difference between the top and the floor can negatively affect your health. This factor is especially dangerous for children and people with weakened immune systems.

It is necessary to insulate the floor in the bathhouse. For this, different techniques and materials are used, which are selected taking into account the individual characteristics of the building.

Types of insulation

Expanded polystyrene

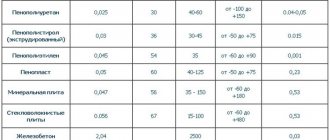

Making insulation with your own hands is not difficult. It is important to choose the right material and installation method. The following heat insulators are placed on the floor of the bathhouse:

- Polystyrene. Inexpensive material with low weight and good rigidity. It is convenient to cut it with a regular knife. For use on wood and concrete floors.

- Styrofoam. Traditional insulation with low thermal conductivity, which is suitable for any structure.

- Minvata. Suitable for wooden floors. Has good thermal insulation properties. Disadvantages include moisture absorption, so waterproofing is required.

- Expanded clay. Placed on concrete. Can be used as a base and as a filler for filling the first layer. The disadvantage is the high cost.

- Perlite. Used on concrete. After creating the mixture according to the instructions, it is an expanded solution that is poured between the base and the top screed. Has high strength.

- Penoplex. It is moisture resistant, durable and resistant to mechanical stress. It is a type of polystyrene. Insulation of the floor in a bathhouse with penoplex can be done on wood and concrete.

- Vermiculite. Rarely used due to high price. Holds heat well and is resistant to open fire.

Perlite

Styrofoam

Expanded clay

Mineral wool

Penoplex

Vermiculite

The listed heat insulators have been used for a long time and are time-tested. But there are also more modern methods of floor insulation that are applicable to concrete. These include slag from the boiler room, which serves as a good alternative to expanded clay. Traditional methods include thermal insulation with glass or plastic bottles. The flooring is laid on top of them.

You can also install a warm electric floor in the bathhouse.

Floor insulation device with water and electric heating

A modern option for insulating floors in a bathhouse is to install water heating underneath them. This creates additional convenience, but is more complex and expensive . To operate a heating system with circulating water, it is necessary to purchase a heating boiler and a water pump, pipes and fittings.

In addition, the work requires preliminary design and highly qualified specialist workers. It is very difficult to independently cope with floor insulation by laying a water circuit . Instead of water, antifreeze, its mixture with water, or ethylene glycol can be used.

Electrically heated floors are an easier task for installing a do-it-yourself insulation system. Film infrared mats or ready-made “cable floors” are used as insulation. The advantageous aspect is that in the event of a malfunction in the electric heating, it will be enough to replace one of the units. Even if it fails, the others continue to work. To find a defect and repair water heating, it may be necessary to dismantle the tiles and the entire concrete screed.

The high cost of insulating floors in a bathhouse using modern methods is undoubtedly a temporary phenomenon; the production of components is growing and their cost is decreasing, the standard of living is rising. The bathhouse will always remain a favorite place of relaxation for many people, and in the pursuit of comfort, even newer technologies and materials will be used to insulate the floors.

Requirements for insulation of different rooms

A traditional bathhouse has several compartments. A washing room or steam room is a place exposed to copious amounts of water. Good waterproofing is needed here, otherwise fungus and mold may form. The heat insulator should not change its properties under the influence of water, so you should not place mineral wool in the steam room.

In the rest room and dressing room, the requirements for thermal insulation are not as strict, since the humidity and temperature are lower.

What materials should be used for floor insulation?

Materials for floor insulation

High humidity and temperature, which are constantly present when using a bathhouse, dictate a careful approach to the selection of materials used for thermal insulation of floors. In an ordinary room that does not have such extreme operating conditions, you can use almost any mineral-based insulation. But when thermally insulating the floor in a bathhouse, experienced builders recommend using thermal insulation material with a cellular structure. The most suitable material that meets all high requirements is polystyrene foam of all types. It is widely used for insulating floors in rooms with high humidity.

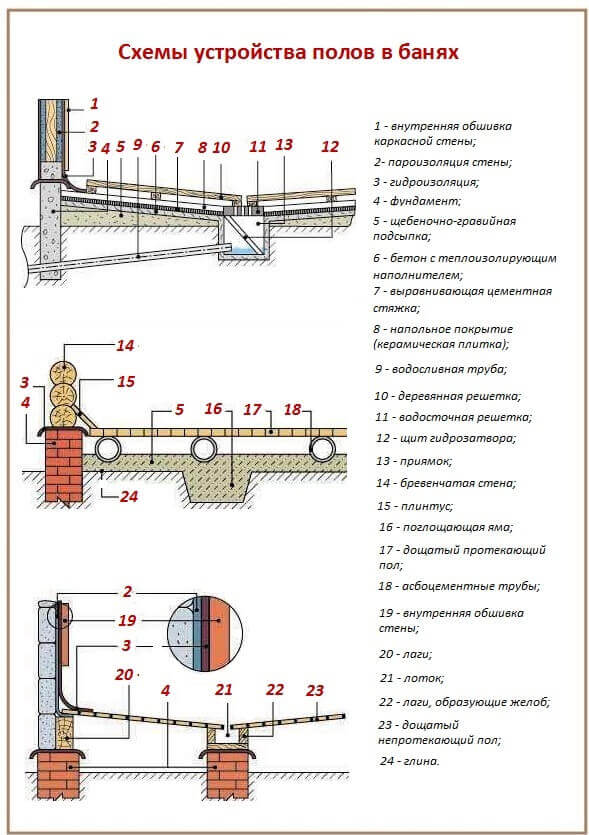

Scheme of floor insulation with a drain in the bathhouse for drainage

There are several approaches to the question of what material should be used for flooring in bathhouses. So, it can be made of concrete, or it can be made of wood. When insulating floors of all types, there are some general rules, which we will tell you about.

Scheme of the floor arrangement in the bathhouse

Necessary materials

The choice of tools for insulation is individual. An approximate list of materials and equipment for insulating a wooden floor:

- Ruberoid, glassine, sheet foam. They are used for waterproofing or vapor barrier.

- The insulation itself. It is selected based on the chosen installation method and the financial capabilities of the owner.

- Cement, sand, water. Necessary for preparing solutions if they are to be used as a heat insulator.

To insulate a concrete floor, you need:

- Coating waterproofing and roll. This could be bitumen mastic or roofing felt.

- Insulation.

- Cement, water, sand.

The calculation of the amount of materials depends on the individual characteristics of the room. The tools you will need are a ruler, a knife, a square, a level, a pencil, a hammer drill, and dowels. First you need to carry out calculations and create a laying diagram. It is necessary to provide a place for drainage and discharge of water.

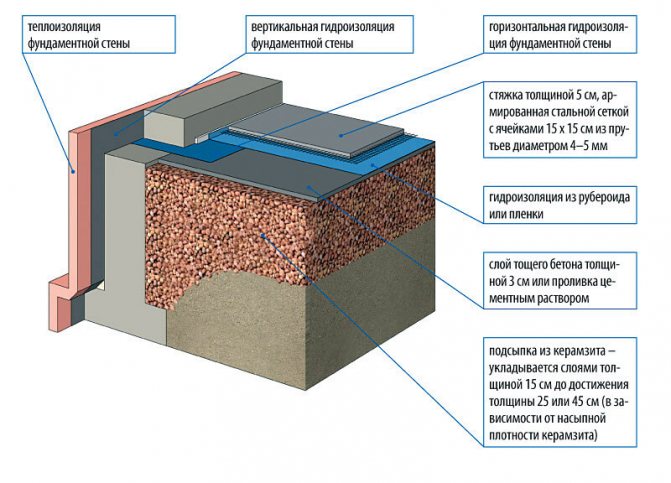

Insulation with screed on the ground of a concrete floor

Insulation with screed on the ground of a concrete floor

This insulation method has good efficiency and reliability. A multilayer structure will be considered, which can be changed depending on the climatic conditions of residence. A layer of dry concrete (about 5 cm), foam concrete (10 cm), expanded clay (15 cm), sand cushion (15 cm) is laid. The thickness can also be changed.

Algorithm for thermal insulation of a sauna:

- Marking. The height of the coating should be located at the level of the subfloor, which must be taken into account when choosing the number of layers. These marks for each layer should be applied to the walls.

- Leveling the land. Can be done with a shovel “by eye”, without using a building level.

- Laying a layer of dry sand on the ground or clay. Used to dampen vertical loads during soil heaving. Do not pour water on the sand to compact it.

- Laying expanded clay. It can be replaced with porous waste or slag.

- Pouring expanded clay with concrete. To obtain a porous structure, special subsidence is added. You can buy them at a hardware store. The concrete should stand for 2-3 days to dry completely, and only after that can work continue.

- Laying the finishing coating or creating a cement-sand screed. The second option allows you to increase the strength and reliability of the structure. It is recommended to screed with dry concrete on a reinforced mesh.

The finishing coating - tiles or other material - can be placed on dry concrete on the second day.

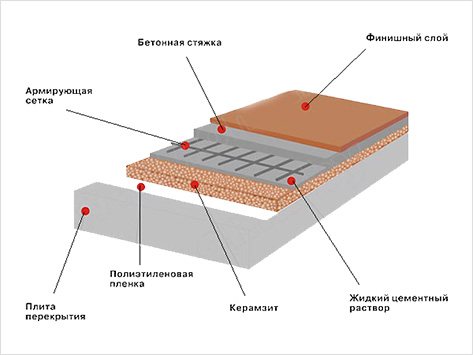

Insulation on the floor slab

Insulation on the floor slab

With this installation, a layer of thermal insulation is laid over the floor slab on the foundation. It must first be covered with a layer of waterproofing. A reinforced mesh is placed on top, which is filled with a cement-sand screed. When the concrete has dried, the final coating can be laid.

Expanded clay can act as thermal insulation. In this case, the following steps are performed to insulate the floors in the bathhouse:

- A thick layer of polyethylene film is placed on the rough concrete floor. It also needs to be placed on the walls.

- Marking the finishing level, placing beacons along it.

- Laying expanded clay. It can be filled directly from bags or by mixing two different fractions. Both methods provide good thermal insulation.

- The embankment is leveled and secured with a surface layer of cement.

- If necessary, a reinforcing mesh is installed.

- Pouring the expanded clay layer. The height of the screed is 30-40 mm.

- Removing air bubbles using a special roller.

When the floor is dry, you can apply the final coating in the washroom.

Stages of floor insulation in a bathhouse

Depending on what kind of floor base is provided in the bathhouse and what type of flooring is supposed to be laid, the insulating “pie” varies radically both in thickness and in its “filling”.

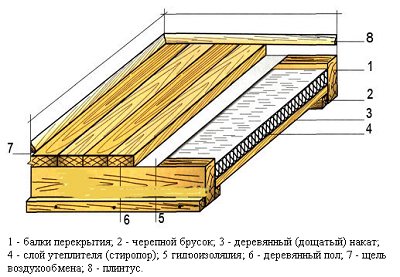

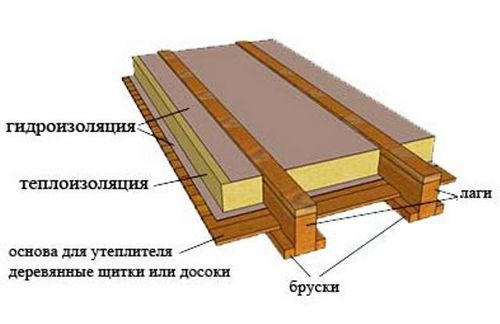

Stages of insulation of a wooden floor in a bathhouse:

Stage 1. Subfloor boards are nailed to the wooden floor beams with a gap 1-2 boards wide. Stage 2. A windproof film, for example, Ondutis A100 or A120, is laid on top of the subfloor and joists. The canvases are secured to the protruding elements of the base using a stapler. Stage 3. A layer of insulation is laid on top of the vapor and waterproofing layer. It is optimal if it is equipped with foil coating - this will significantly speed up the process of insulating the bathhouse floor. If you purchased a heat insulator without foil, you can use Ondutis R Termo vapor barrier film, which not only effectively protects the insulation from getting wet, but also has heat-shielding properties at the same time. Stage 4. To complete the insulation, lathing is nailed to the joists - bars 3-4 cm high, which will ensure the proper level of floor ventilation, and then a finished floor covering of wooden boards is laid.

The sequence of insulating a concrete floor in a bathhouse:

Stage 1. A waterproofing film with a vapor barrier effect is laid on concrete floor slabs installed on piles, or on a monolithic concrete base poured on the ground, or a coating mastic is used. Stage 2. Lay mineral wool or polystyrene insulation boards, fill in expanded clay, slag, or spray foam polymer mixtures. Stage 3. Install the reinforcing mesh and pour the screed. Stage 4. Lay a ceramic or wooden floor covering (with preliminary installation of plywood or sheathing and vapor barrier).

Features of wooden floor insulation

Thermal insulation of a wooden floor in a bathhouse

The technology for thermal insulation of wood floors is similar to working with concrete. But you need to take into account a number of nuances in order to properly insulate the floor in a bathhouse under a wooden floor:

- Insulation. The best option for the floor is polystyrene foam in the form of mats. It does not allow moisture to pass through, so no waterproofing layer is required.

- Preparing the rough plank floor. It can be made from low-grade boards that will be attached to the joists.

- Waterproofing. The membrane is designed to reduce the impact of steam and water on beams and subfloors. When laying, it is important to close all joints and allow for allowance on the wall.

- Final sealing of holes with polyurethane foam, cleaning of the floor. It is recommended to lay the finished floor at a distance of 4 cm from the lower level. This will ensure good ventilation and quick drying.

Closed cellular structures should be used in the steam room and sink. Mineral wool and other porous materials should be placed in the rest room and dressing room.

Insulation of concrete floors

Unfortunately, insulating an old concrete floor is labor-intensive and not easy. It’s good if the height of the room allows you to build the entire structure using old floors as a rough version. If this goes against the parameters of the bathhouse and the communications available in it, you will have to remove the concrete screed using a jackhammer or primitive construction tools: a crowbar and an ax.

Next, the algorithm of actions is as follows:

- A rough concrete screed is made on top of the floor slabs.

- Waterproofing is placed on the screed. This can be thick polyethylene film. It spreads over the entire surface and at the same time protects the walls. To do this, the film must be wrapped at the edges by at least 5 cm. The joints between the panels are overlapped and fixed with tape.

- The next stage is laying insulation. What makes concrete floors convenient is that almost any type of material is suitable for their insulation. You can use slabs of ordinary polystyrene foam, which is usually installed in two layers. The joints between the sheets can be clogged with remaining material or filled with polyurethane foam. Insulation with polystyrene foam gives excellent results at a minimum cost.

- A wooden frame is placed on top of the insulation. Using long self-tapping screws on dowel plugs, it is attached to the floor.

- A small layer of concrete, approximately 2–3 cm, is poured on top so that the structure of the frame with insulation becomes solid. The preliminary screed on the insulation is called reinforcing.

- The next layer is a rough leveling concrete screed. The thickness of the fill is 5–8 cm.

- The last step will be the final pouring of cement mortar or laying of ceramic tiles.

According to generally accepted rules, the floors in the steam room are poured with concrete, and in the rest areas and dressing room they are made of wood.

Insulation on wooden logs

Floor insulation using joists

The installation algorithm is as follows:

- Logs are made from wood with dimensions of 50×180 mm. They should be laid on a foundation strip or piles. The distance between the logs should be equal to the width of the heat insulator.

- Skull blocks should be secured along the bottom of each joist. A subfloor made of boards is then laid on them.

- Laying waterproofing. Polyethylene or PVC can be used as film.

- Laying thermal insulation into the resulting cells.

- Covering the insulator and joist with a layer of waterproofing. All joints should be glued with construction tape or special tapes.

- Laying floorboards.

When working, it is important to lay materials so that there are no holes. Water can get into them, causing the thermal insulation properties to deteriorate and mold to form.