The roof separates the upper floor

home from cold street air and precipitation, therefore, to ensure maximum thermal efficiency of the house, it needs to be insulated.

More information about heat loss

and ways to reduce them, you will find in the article Insulating the house.

In this material we will talk about why it is necessary to insulate a roof, what they are, how to insulate them using sawdust, what materials and technologies are best suited for different types of roofs, how to avoid mistakes, as well as what safety measures need to be followed.

Any part of the house that comes into contact with outdoor air

transfers thermal energy from the house outside in winter, and from the street into the house in summer.

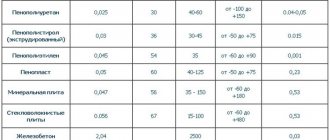

The higher the thermal conductivity of the material,

from which this or that part of the house is made, the greater the heat loss in winter and heating in summer.

In addition, with temperature changes there is a high risk of dew,

after all, the moisture contained in the air always settles on cold surfaces and the greater the temperature difference, the more moisture will fall in the form of dew.

Dew droplets permeate wooden and concrete structures, increasing their humidity.

This phenomenon in summer leads to the appearance of mold and rot, and in winter the water in the pores and capillaries freezes, destroying any materials.

Therefore, it is very important to insulate the roof, because it separates the ceiling or attic from the street air

. Insulating the roof not only reduces heating costs, but also seriously extends the service life of the upper floor ceilings, as well as elements of the roof truss system.

Types of roofs

All roofs can be roughly divided by the number of slopes

.

Single-pitched ones are the simplest

in production, but are ineffective, because the roofing material only protects from wind and precipitation from one direction.

Gables are more efficient

, because they are protected from two directions, but hipped roofs provide maximum protection from wind and precipitation.

A further increase in the number of slopes no longer affects the effectiveness of the roof.

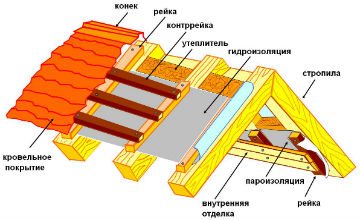

The roof structure directly affects

on the method of insulation, because in single- and double-slope roofs it is necessary not only to install insulating material, but also to seal the remaining uncoated sides.

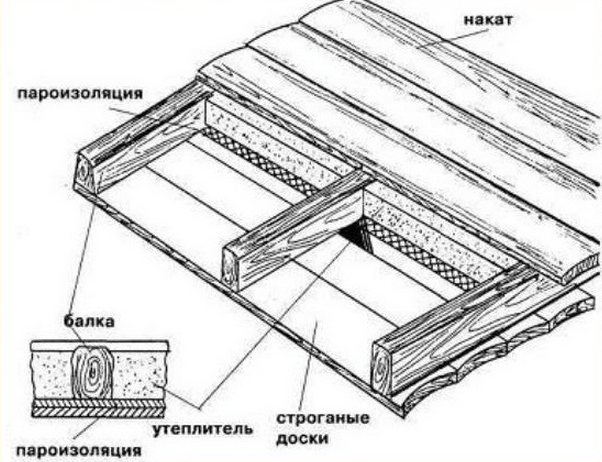

Regardless of the number of slopes, all roofs that can be insulated with sawdust are constructed according to the same principle

. The ceiling of the upper floor simultaneously serves as the floor of the attic.

The elements of the rafter system are fixed along the edge of the attic

, which provide the necessary slope and the desired shape of the roof.

If free space allows, then in the attic you can make an attic - a residential or non-residential room,

which will also be part of the roof.

On roofs with a corrugated covering (slate, tiles, etc.), street air enters through the voids,

formed by waves of roofing material and exits through special ventilation holes or pipes.

If the roof has a “soft roof”, that is, smooth sheets of cardboard impregnated with bitumen, then the attic ventilation must be done with a separate system

. After all, there are many places inside the roof where temperature changes lead to condensation and increased humidity.

If there is no ventilation,

or it is not organized correctly, then the condensation that falls will lead to rot, mold and other problems.

Main stages of repair work

To reduce heat loss

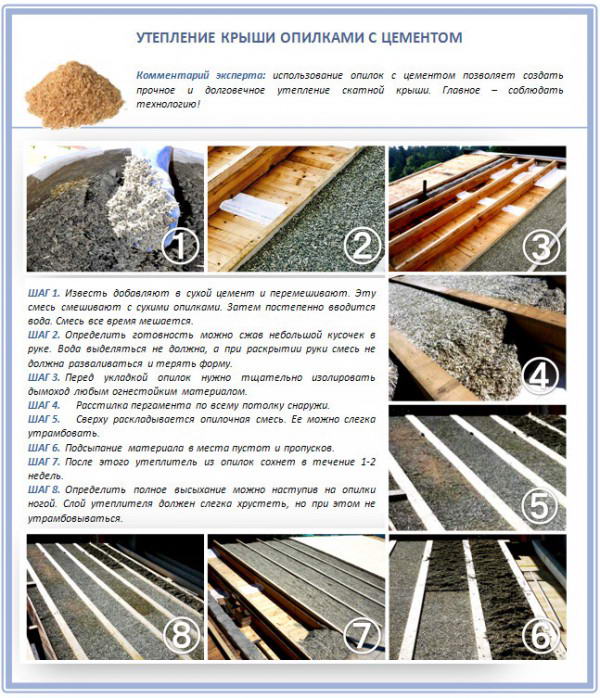

roofs using sawdust perform the same operations as when using any other insulating material.

These include

repair of the rafter system and roof, organization of proper ventilation, as well as insulation:

- roofs,

- attics,

- attic floor,

- chimney and ventilation pipes.

First of all, it is necessary to conduct an audit of the rafter system

, roofing and floor elements, because repairing them after installing the insulation will be much more difficult.

After this, it is necessary to consider the ventilation system,

so that the air circulation it creates covers the entire internal space of the roof, and it is necessary to provide the ability to block the movement of air.

After all, after insulation, the temperature in the attic will differ

from the street, warmer in winter and cooler in summer.

Excessive constant ventilation will reduce the insulation effect to a minimum, while insufficient ventilation will lead to condensation, rot, mold and other problems.

Only after this they begin to choose a method

insulation with sawdust, that is, using:

- dry mixture of sawdust and lime;

- liquid mixture of wood sawing waste and various binders;

- finished slabs.

Regardless of the insulation method, it is also necessary to consider a waterproofing system.

After all, in winter the temperature of the roof is much lower than that of the insulation, so the air passing between them will leave

drops of dew on a cold surface.

But you cannot fill the entire space up to the roofing material with insulation, because in this case you will disrupt air circulation

and condensation will begin to accumulate.

Most often, waterproofing is done using various films,

Moreover, their choice depends on the type of attic ventilation.

If you have provided for forced or natural air movement in the attic, then you can lay regular cellophane film

, it will prevent moisture from moving both up and down.

If for some reason you have not equipped the attic with ventilation,

or its effectiveness is insufficient, then it is necessary to use a vapor-permeable film. This method will protect the insulation and joists from water, but will not impede the movement of steam.

As a result, excess moisture will pass through

through the film and leave along with the movement of air between the insulation and the roofing material.

Roof thermal insulation

This method is best suited

specifically for the roof. After all, with minimal financial costs and low labor intensity, it provides a sufficient reduction in heat loss for this section of the roof.

The roof is insulated to reduce the amplitude of temperature differences

between the attic and the attic or room on the top floor, therefore, great efficiency is not required from the insulating material.

In addition, the width of the rafters usually exceeds 10 cm

, and such a layer of a mixture of sawdust with any binder is similar in effectiveness to mineral wool 6–7 cm thick or polystyrene foam 4–5 cm thick.

In this case, the thickness of the insulation is quite sufficient

to reduce the amplitude of temperature differences.

on the roof to load the mixture ,

consisting of rafters, waterproofing film and lining.

Due to its low specific gravity,

As a lining, you can use plywood 5–7 mm thick, or fiberboard 10 mm thick.

to the rafters using a stapler

, if you don’t have it, you can get by with self-tapping screws and a tin strip 2–3 cm wide.

The lining is placed in strips 1 m wide

.

It is not advisable to use wider strips, because it will be difficult to compact the insulating mixture. After this, fill the cavities with the mixture and compact

it with any suitable piece of wood. Do not be too zealous with the seal, because you can damage the waterproofing.

Having filled one row with insulating material, install the lining of the second row

and also fill it with a mixture of sawdust and lime. In the same way, fill the entire under-roof space up to the ridge.

The last row is desirable

make it 10–20 cm wide, so it will be easier to fill it with insulating material. In addition, the lining is first lightly attached to the rafters from below, then the cavity is filled with material and the lining is pressed to the rafters, after which it is fixed normally.

You can also use solutions consisting of sawdust with water and a binder, but the best effect is achieved

only a mixture of sawdust and PVA.

After all, other compounds are afraid of high humidity, so if the roof is damaged, they can deteriorate. In addition, the specific gravity of the insulation, in which water acts as a solvent or activator of the binder, is much higher than that of PVA-based mixtures.

Therefore, they have to make a more durable and thick lining

.

In addition, the use of slabs gives good results

from a mixture of sawdust and PVA, because such slabs can be prepared without haste throughout the year, and installed in spring or summer. Both methods of insulation are described in more detail in the article.

Attic repair using sawdust

The roof separates the attic room from precipitation

, so here you can use either a dry mixture of sawdust and lime, or any solutions.

The use of homemade slabs also gives good results.

, however, for them we recommend only cement and PVA as binding materials.

After all, other materials do not provide the required strength,

therefore, there is a risk of damaging the slab during lifting into the attic.

If you install ready-made PVA slabs in a heated attic, you can do without waterproofing,

after all, hardened glue is not afraid of water, and its ability to transmit water vapor is sufficient to prevent condensation from accumulating to dangerous amounts.

If you use slabs made of sawdust and cement, then it is still better to install waterproofing, it will separate the condensation

, settling on the slab and wooden parts, so that its quantity does not reach dangerous values.

The walls of an unheated attic can be insulated with any materials

even without the use of waterproofing, because the temperature difference does not reach values at which heavy dew falls.

To insulate the attic , use the same technique

which we talked about in this article. The only difference is that the outer surface of the insulation does not need to be covered with a facade, because precipitation does not fall on it.

Insulating the attic floor

In many ways, this operation is similar to those performed when insulating any floor.

The only difference is

that there may be no coating on top and the temperature difference with an uninsulated roof is much higher than on the floor in the room.

In addition, the bulk of the condensate

falls on the insulation in the mornings from late spring to early autumn, when the air temperature outside is noticeably higher than the temperature on the surface of the attic floor.

Even if you use gypsum or cement as a binder, it will not harm them,

because by lunchtime the attic warms up, the moisture evaporates and leaves through the ventilation system.

In details

Read about such work in the article about floor insulation.

In addition, it is necessary to take into account the presence of insulation of the roof and walls.

If you insulate them, then the temperature difference

in the area of the attic floor will be insignificant, so you can do without waterproofing.

If there is no such insulation, then it is necessary to lay a vapor-permeable film

both under and above the insulating material, this will provide maximum protection against condensation and extend the service life of the floors.

Finishing of chimneys and ventilation pipes

Ventilation and chimney pipes are insulated to reduce the likelihood of

on their internal surfaces of condensation, which falls when hot gas comes into contact with a cold surface.

street or room air is used to burn fuel

, which is why the smoke always contains a small amount of water vapor, which settles on the cooled walls of the chimney in the form of condensation.

Therefore, the less influence of the attic temperature on them, the lower the likelihood of condensation formation.

, which harms both the ventilation system and the chimney masonry.

When insulating ventilation pipes, it is necessary to take into account that in winter their surface temperature is much higher, and in summer much lower than the temperature in the attic, but the difference rarely reaches dangerous values, so there is no need to worry about condensation.

To insulate them, you can use a mixture of sawdust with any binder

, so they use what is easier to get. This is usually clay that can be dug up in most vegetable gardens.

When insulating a chimney, another problem arises - its surface temperature often exceeds 150 degrees, so it is necessary to use only compositions based on non-flammable binders

substances.

Clay is the most convenient, because its coefficient of thermal expansion is much closer to brick than that of cement or gypsum, so even if the pipe is very heated, the insulating layer will not become cracked.

Moreover, the proportions

sawdust and binder

should not exceed 2:1

, because the more wood sawing waste there is, the higher the likelihood of fire.

The pipes are coated with ready-made compounds.

If it is not possible to make a layer of the required thickness, then first apply a layer of small (2–4 cm) thickness along the entire length of the pipe, then wrap it with little force

twine or thin nylon rope.

Next layer

cement insulation can be applied after 10–15 hours, gypsum after 30–40 minutes, PVA-based after 5–7 hours, and clay after 2–3 days.

Therefore, when working with gypsum, cement or PVA, it is necessary to mix as much solution as is sufficient to create

one insulating layer.

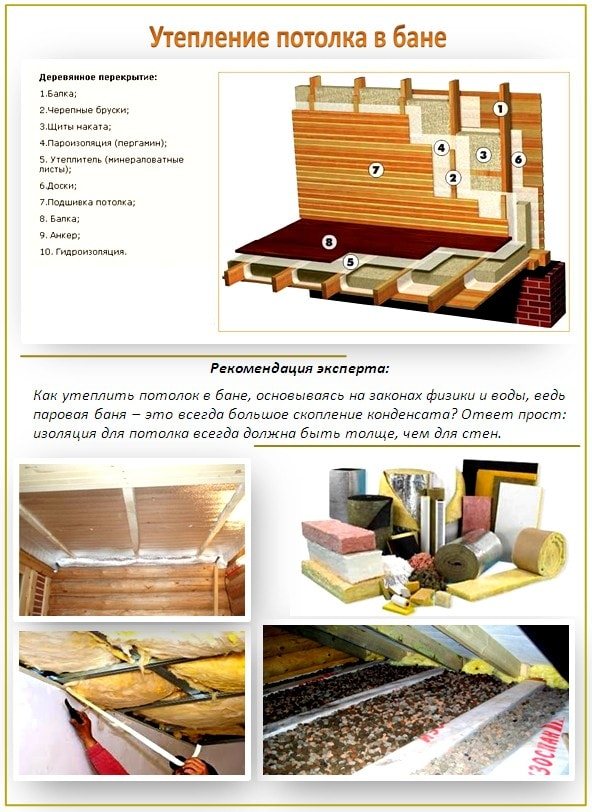

Materials and methods of insulation

Let's look at several methods by which you can organize insulation with your own hands, and also list the main materials suitable for this. The principle of installing a high-quality vapor barrier for a steam room is the same in all cases. The only difference may lie in the features of the ceiling structure.

What can be used

Many different materials are used to properly insulate the ceiling in a bathhouse. There are natural and artificial means. The choice of material may be determined by financial capabilities, as well as skills that contribute to the high-quality implementation of installation technologies.

Expert recommendations

The bathhouse was not invented today or yesterday. Over time, technologies for arranging a steam room with your own hands were developed and improved. Thanks to their observance, the healing effect even increased. Once upon a time, insulation could be done with sawdust, clay, straw, or wood chips. For better effect, a combination of these materials was carried out.

Note It is a mistake to believe that to effectively retain hot air, it is enough to lay out a layer of straw and press it with clay on top. It is also important to consider the effect of temperature inside the steam room itself.

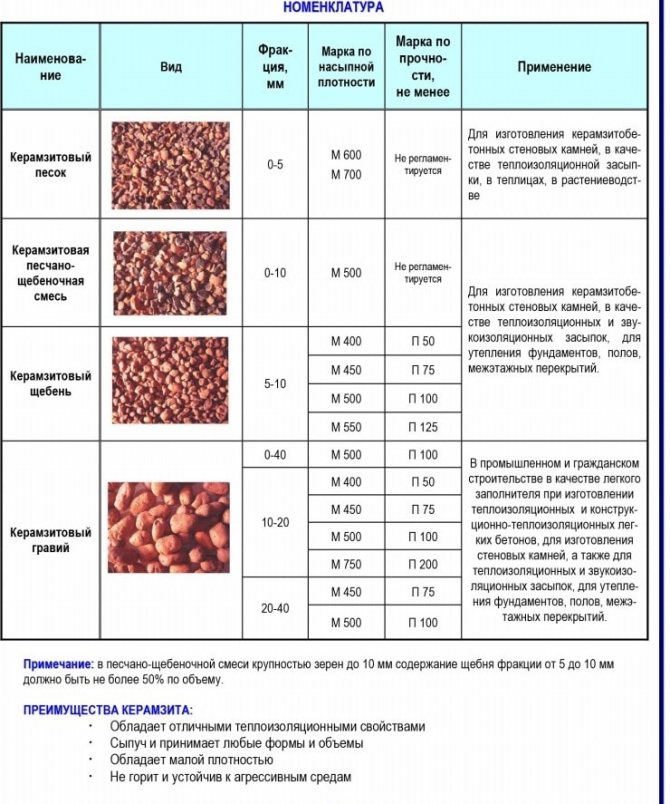

Today, insulation can be done with expanded clay and other artificial means. This is easy to do yourself. Each material has its own characteristics that must be taken into account. The most common artificial materials are polystyrene foam, penoizol and mineral wool.

Which material is better?

All materials for thermal insulation have their own characteristics and can perform better or worse, depending on the type of building structure. The most universal remedy can be called ordinary mineral wool. Heat retention is ensured by the voids formed between the woven basalt fibers. The resulting material can ultimately be used for do-it-yourself insulation. A disadvantage of mineral wool may be the loss of the ability to retain heat after interaction with moisture.

Insulation with mineral wool

This method differs from the simple method of insulation with sawdust. To install mineral wool correctly, it is necessary to lay a layer to ensure waterproofing. This is a small gap between the insulation and the vapor barrier.

We offer you a modern method of insulation, suitable for steam rooms with and without an attic. All materials must be attached to the floor beams. This method of insulation is the simplest, most effective and inexpensive. Preliminary preparation of the tree will be required. It must be treated with your own hands with a special antiseptic to prevent the occurrence of fungi.

Insulation is carried out from the side of the under-roof room

For vapor barrier, you can use the usual method or install an additional aluminum layer. It is better to use foil insulation for this. Fuel consumption for maintaining high temperatures will be reduced due to the heat reflection capabilities inherent in this material. You will need a construction stapler. The seams on all films must be sealed. The purchase of additional materials will be justified by high vapor barrier properties.

Laying vapor barrier material

To maintain the insulation, you can install sheathing. It should be attached perpendicular to the beams. The sheathing can support the ceiling sheathing. It is necessary to leave a gap on one side between the sheathing and the vapor barrier material.

From the outside, between the beams on the ceiling of the steam room, you can lay out mineral wool. There should be no gaps left. There is no need to be afraid to use force to ensure that the insulation fits into the niches as tightly as possible. The distance between the beams should be slightly less than the width of a standard mineral wool block.

Laying mineral wool

Thermal film or polyethylene is placed on top to protect against moisture. Remember that there must be a gap between the waterproofing and the insulation.

Laying waterproofing material

The covering material can be chosen at your discretion. Linden lining is most often used for these purposes. To protect the insulation materials, it is recommended to install a plank floor in the attic.

Insulation with sawdust and clay

By insulating a bathhouse with sawdust, sand or clay, you can significantly increase the ability to retain heat in a building with an attic. First of all, it is necessary to lay a vapor barrier on the attic floor. When insulating with sawdust, you can use roofing felt. The strips are laid with an overlap of 10 cm. Sprinkle with sawdust so that a twenty-centimeter layer is formed. Then clay or sand is laid. The layer of soil above the sawdust should reach 5 cm.

Insulating a bathhouse ceiling with clay

The material can be found in numerous carpentry shops. The processing humidity here is quite low. In such workshops there is always a lot of dry shavings. Once upon a time, an additional layer of ash was laid out over the sawdust. Today, a membrane is used for this. There needs to be a gap between the insulation and the floorboards for ventilation.

Insulation with expanded clay

Floor ceiling with expanded clay

Work on insulation with expanded clay is often carried out. The only drawback of the material is the ability to absorb moisture.

This method of insulation will require additional vapor barrier of the ceiling. Expanded clay can be poured onto the film in a thirty-centimeter layer. Another level of waterproofing is laid on top. Expanded clay insulation is the easiest way to retain high temperature air.

Comparison with other insulation materials

Despite the fact that in terms of the ratio of layer thickness to the level of heat loss reduction, sawdust and any mixtures based on them are inferior to any modern heat insulators, this type of insulation is still in great demand

.

After all, insufficient thermal efficiency compared to other materials is compensated by low requirements

to the level of thermal insulation on the roof, as well as the difference in price.

Even if you couldn’t get sawdust for free, their cost will still be much lower

prices of any modern insulation.

Read more about the difference in prices between wood sawing waste and modern insulation materials.

Another plus

sawdust is that when used correctly, rodents do not live in them, and various insects do not live in them.

But it is rodents and insects that are the main problem

those who insulate the house with mineral wool, polystyrene foam and other modern heat insulators.

The third plus

Particularly relevant in roof conditions is that sawdust does not emit toxic substances when heated.

In summer, the roof surface heats up to a temperature of 60–100 degrees, which leads to air heating even in an insulated attic to a value of 45–55 degrees.

At this temperature, polystyrene, foam plastic and many other insulation materials emit toxic substances, so the use of sawdust is much less dangerous.

Forums

We have prepared links to the most popular forums on the Internet. There, not only those who learn to do something with their own hands, but also serious specialists, including builders and engineers, participate in the discussion of issues:

Wood sawing waste;

- How

such insulation

differ

from thermal insulation using modern materials? - Price. Since the material is waste from sawmills and sawmills, they are often given away for free. In such a situation, the price will only be the cost of delivery to the construction site.

- Safety. Wood shavings do not produce toxic fumes that cause poisoning or skin irritation.

- Thermal conductivity. Dry sawdust has a large number of air cavities, which provides excellent thermal insulation. Thermal conductivity is lower than that of a full-fledged wooden beam.

- Organic. The chips retain all the properties of their parent - wood. This insulation “breathes” and allows moisture to pass through with the air.

- Installation. To insulate a roof with sawdust, you do not need to use complex tools or be an experienced builder. The methods for preparing the mixture and laying it on the floor are easy to implement.

Insulating a roof with sawdust is an inexpensive and simple way to protect yourself from the cold winter. The technology is time-tested and accessible to most people. It has its pros and cons, we will look at them in this article. In addition, you will learn about methods for preparing thermal insulation mixtures and insulation methods.

Sawdust is bought at sawmills; it is a product of the wood processing industry. Due to its natural origin, such insulation is harmless to human health. This material has long been used for construction in Rus'. Currently, sawdust is still used in the thermal insulation of buildings. They have several advantages that distinguish them from other insulation materials:

Despite all the advantages, sawdust has become less commonly used in insulation due to significant disadvantages:

- Flammability. Like any wood, shavings are flammable.

- Biological factors. The shavings harbor rodents, mold, insects and other dangerous organisms.

- Humidity . The material absorbs moisture due to which it loses its thermal insulation characteristics.

Before using sawdust, they are treated with fire retardants and an antiseptic. This increases the protection of the insulation from negative factors.

Insulation methods

The choice of material will also determine the method of insulating the ceiling in the bathhouse. The thickness of any insulation should be from 50 to 100 mm. The thicker, the better, but more expensive.

Use of expanded clay

The use of expanded clay is a natural thermal insulation for the ceiling of a bathhouse. Expanded clay is used mainly in those regions where in winter the temperature drops to -300. The thickness of the layer of material used should be at least 10 cm. Experts recommend not mixing expanded clay with sawdust. Although such a mixture increases the thermal insulation of the ceiling, sawdust absorbs moisture very strongly, and mice can also take root in sawdust.

Therefore, it is better to use small fragments of expanded clay along with large ones; in this case, the small fractions will fill the space between the large parts. The insulation method is quite simple - expanded clay is simply poured onto a layer of steam and waterproofing, since expanded clay is afraid of water.

Use of polystyrene foam

Foam plastic is used as bathhouse ceiling insulation, but experts warn about caution with high temperatures. Therefore, it is impossible to insulate the ceiling above the steam room with layers of foam plastic. The use of polystyrene foam as an insulating material is permissible only on the outside of the ceiling. In this case, you should choose construction foam with a low degree of flammability.

Application of mineral wool

It is recommended to use mineral wool as ceiling insulation, as well as foam sheets on the outside. In this case, you should choose cotton wool in rolls coated with foil. Firstly, the foil helps return a large amount of warm air back into the steam room of the sauna. And, secondly, mineral wool prevents cold air from entering the bathhouse from the attic.

When choosing between polystyrene foam and mineral wool, you should choose cotton wool, since it is more natural and less susceptible to combustion than polystyrene foam.

Application of polypropylene foam

When insulated with polypropylene foam, a “mirror reflection” effect is created thanks to the foil. This material also contributes to the fastest heating of the steam room.

Insulation with clay and sawdust

Many lovers of environmentally friendly and relatively inexpensive raw materials choose the insulation method with clay and sawdust.

When applying this method, the following main steps are distinguished:

- First, the first layer is laid - this is a vapor barrier.

- The second layer is a mixture of clay, a small amount of water and sawdust (straw can be used instead of sawdust). The mixture must be kneaded until thick and the layer thickness should be from 5 to 8 cm. Or do it in another way: a clay layer, then add a layer of expanded clay and secure it with another layer of clay on top.

- An indispensable condition is that the ceiling surface must be carefully insulated.

- The drying time for this layer takes approximately one month. Then you need to apply the clay mixture to the surface again and let it dry.

- The final step is to cover the surface with sawdust or expanded clay.

This method is quite a good option and is used as a method of insulating the ceiling of a bathhouse with your own hands. But natural insulation materials are short-lived (with the exception of expanded clay), can be damaged by rodents over time and absorb moisture.

Preparing the insulation mixture

Methods of insulating the roof and attic vary depending on how the space is used. Residential attics are insulated from the side of the slopes and interfloor ceilings. If the attic is used only for storing things, then it is enough to insulate only the ceiling from the cold. In any case, not only thermal loads are taken into account, but also the appearance of condensation.

The installation process involves filling sawdust into the design cavities. The only problem is the gradual shrinkage of the insulation. At the same time, the thermal insulation properties decrease. To reduce the effect of this drawback, the chips are mixed with other materials. Three common recipes are:

- Adding lime and gypsum. First, 85% sawdust is mixed with 10% lime. Then add 5% gypsum with water. Lime is added to the composition to protect against rodents.

- Cement. In the summer, 10 buckets of sawdust are mixed with 1 bucket of cement. For this volume, add 25 grams of copper sulfate to the water. The resulting solution is laid on floors 8-10 cm thick. After two weeks, the layer will dry and the work will be completed.

- Clay. In a large container, the clay is mixed with water until the mixture becomes semi-viscous. Next, add sawdust in small portions and mix it constantly. This insulation is laid in several layers until the total thickness reaches 10 cm. This recipe is better than others, since it protects the insulation from fire, is low cost and does not contain hazardous substances.

Sawdust insulation, 15 cm thick, has insulating properties equal to a 10 cm layer of mineral wool. Although the cost of its use is 6 times less, the weight of the roofing cake increases by 2-3 times. Therefore, it is necessary to strengthen the rafter system with supports.

The concept of thermal insulation of a bathhouse ceiling ↑

One of the important aspects of bathhouse construction is the design and insulation of the ceiling in the bathhouse. On it, as well as on the roof, there should not be a single loophole left for warm air to escape outside. The purpose of such insulation is not only to preserve heat, it prevents the occurrence of such an undesirable phenomenon as condensation.

On a note

Ceilings in wooden and panel baths differ only in the external cladding of the top: for a built-in one, it is replaced by a roof.

There are certain differences in the technology for insulating the ceiling of a steam room, depending on the presence or absence of an attic space.

- No attic. The ceiling is a flooring made of boards resting on the walls. The boards should be thicker than 5 cm. Proper insulation of the ceiling in a bathhouse involves installing a vapor barrier layer on top of the flooring, on which thermal insulation is laid.

- With an attic. One of the old, but still popular options is to insulate the ceiling in a bathhouse with clay and sawdust. The plank floor is coated with a clay-based composition. The dried composition is covered with insulation, for example, sawdust soaked in cement mortar. Then everything is covered with dry soil in a 5 cm layer.

Insulation of the ceiling of a wooden bath can be done using other materials.

Preparatory work

Before insulating the roof with sawdust, prepare the selected mixture. All wooden structures are treated with antiseptic impregnation. If gaps are noticed, they are filled with polyurethane foam, and the joints between the ceiling elements are also treated. Rotten and damaged parts of the roof are replaced with new ones.

While the preparatory work is being carried out, the sawdust should be dried. Lime and a little copper sulfate are added to them to protect against pests. Previously, these components were replaced with broken glass and chopped dried tobacco.

On the attic floor, between the beams, spread paper or roofing felt. Sheets of lining material are laid with an overlap. The edges are folded onto the beams and secured with a stapler or wide-headed nails. This ensures that the insulation will remain in place and will not leak into the rooms.

In the case where electrical cables and water supply pipes are laid in the attic, their integrity is checked. The wiring is hidden in special sleeves, and the chimney is covered with fire-resistant compounds. These procedures will protect the house from fire, so they should not be neglected.

Features of insulation preparation

For thermal insulation, it is better to choose small chips, as they have lower thermal conductivity. It is worth noting that such sawdust has a large mass and can fly apart during operation. Therefore, kneading of insulation is carried out in calm weather. And in order not to waste time on drying, choose sawdust from finished carpentry.

Give preference to coniferous wood, it contains resin that repels pests.

If the sawdust requires drying, leave it under a shelter for several days. Then treat with antiseptics and mix with lime in a ratio of 10:1. This will serve as additional protection against insects, mice and rats.

Usually sawdust is mixed on special metal or wooden boards. The entire volume of insulation is simply turned over with shovels until a homogeneous mass is obtained.

Installation of insulation

After all the preparatory work has been carried out, you can proceed to insulating the roof. The whole process is divided into several stages:

- Use the boards to make formwork on the attic floor. Substandard boards, even slabs, will be accepted.

- Prepare a solution of insulation from sawdust and the material of your choice. Pour it onto the prepared base. The thickness of the layer depends on the severity of frost in winter. If the temperature does not fall below -20 °C, then 12 cm is enough. But for climate zones with frosts below -40 °C, you will need an insulation thickness of 20 cm. When determining the size of the thermal insulation layer, do not forget about the load-bearing capacity of the floor.

- Using a long rule, level the poured layer and wait until it dries completely.

- After a few weeks, spread waterproofing on top of the hardened insulation. Secure the edges of the rolls to wooden floor joists.

- Finally, lay down sheets of plywood or chipboard and screw them to the joists with self-tapping screws. This layer will be the base for the final floor covering.

If you are insulating an attic roof, then prepare cavities in advance for laying insulation. Also lay the lining layer, then add a mixture of sawdust and lime. Nail the waterproofing film on top. The minimum thickness of insulation in a roofing pie is 20 cm.

As you have seen, the technology for insulating a house with sawdust is simple and accessible to anyone. There is no need for special electric tools, and the entire process, excluding hardening, takes place in 1-2 business days. Work carried out in accordance with the recommendations will protect your home from the cold for ten years.

Experienced builders know that for thermal insulation of cold-type roofing structures, they often use fill-in insulation. They are poured into the space between the joists when arranging the attic floor. This measure will not seem unnecessary if you know that more than 20% of heat loss occurs due to the fault of an uninsulated roof. Most builders agree that thermal insulation is necessary for any heated room. But the issue of choosing a thermal insulation material does not cause such unanimity: some craftsmen use modern technological materials, while others prefer traditional roof insulation with sawdust. In this article we will tell you how you can use wood waste to optimize the temperature regime at home.

Sawdust is a waste product from the wood processing industry, which can be purchased for next to nothing at any sawmill. They are of organic origin, and therefore are absolutely safe for human health and do not cause allergies. Sawdust mixed with clay was traditionally used as insulation in Rus'. Since all residential buildings were built from wood, which Russian soil is still rich in, there was a lot of waste left during the construction process, suitable for thermal insulation of attic floors. Sawdust has the following advantages compared to other thermal insulation materials:

- Low price. Perhaps the affordable cost of this material is the main reason for the popularity of sawdust insulation. Sawmills and sawmills dispose of these production wastes, so they often give them to anyone who wants them, subject to pickup. Therefore, the cost of the material is equal to the cost of delivering sawdust to the construction site.

- Guaranteed safety. Wood shavings are absolutely safe for the health of people living in the house. They do not cause toxic poisoning, skin irritation upon contact, or allergies, which cannot be said with certainty about modern insulation materials.

- Low thermal conductivity. Wood shavings, unlike wood, due to their porous structure, have a low thermal conductivity coefficient, that is, they retain heat well. A mixture of sawdust with clay or lime further increases the thermal insulation effect.

- Organic origin. Wood shavings have all the same qualities as wood. It allows steam and air to pass through, which is fundamentally important for insulating houses made of timber and logs with an attic roof.

- Easy to install. It is very easy to work with sawdust; you just need to mix it with clay or lime and then pour it into the space between the floor joists. The technology for laying insulation does not involve the use of special equipment or complex tools.

Note! The disadvantages of sawdust are the high flammability of this material and low resistance to biological factors. They are a favorable environment for the spread of mold and fungal microorganisms, rodents, and insects. In addition, moisture has an extremely negative effect on sawdust, increasing the thermal conductivity of the insulation several times. To get the maximum effect from thermal insulation of a roof with sawdust, you should pre-treat it with a fire retardant that prevents the spread of fire, as well as with antiseptic preparations.

Basic principles of heat conservation

There are two main types of sauna roofing. We build bathhouses with and without attic space with our own hands. Most often, insulation and vapor barrier of the attic is carried out during the construction process. A much more powerful ceiling gets in the way of the hot air. The space under the roof is also filled with air. This contributes to better air retention in the steam room.

Standard scheme for insulating the ceiling in a bathhouse

Preparing the mixture

In the process of insulating the roof with sawdust, the prepared material is poured into the space between the attic floor joists with a layer of 15-30 cm. A guarantee of high-quality thermal insulation is a dense, non-flowing coating that settles throughout its entire service life. To improve the performance characteristics of sawdust, various substances are added to them, producing wet or dry thermal insulation mixtures. Most often, all professional builders use the following “recipes”:

Important! In terms of thermal insulation qualities, a 15-centimeter layer of sawdust is equivalent to a 10-centimeter layer of mineral wool. But the cost of insulation with wood chips is 6-7 times less than the use of mineral and polymer thermal insulation materials. Experienced craftsmen recommend adding 20-30 cm of sawdust, which will take 2-3 weeks to dry and shrink.

Installation technology

The effectiveness of roof insulation with a thermal insulation mixture based on sawdust and clay or lime depends on the correct installation, as well as on the quality of the preparatory work. It is necessary to treat wood shavings with preparations, fire-retarding compounds, an antiseptic, and add substances that repel rodents and insects. Insulation of a cold roof with sawdust is performed in the following sequence:

- The wiring running through the attic floors is insulated and stored in metal pipes. Chimney pipes, air ducts and other communications are finished with fire-resistant material or covered with crushed stone.

- Using wooden boards, formwork is installed on the subfloor. For this operation, you can use substandard wood or slab.

- To protect the sawdust from moisture, a waterproofing material (high-diffuse membrane or glassine) is spread on the surface of the subfloor, secured with a construction stapler to metal staples.

- The thermal insulation mixture of sawdust and clay or lime is mixed in small portions, and then, without delay, evenly poured onto the waterproofing material in a layer of 25-30 cm. If a dry mixture is used, it is additionally compacted.

- The thermal insulation layer is carefully leveled and then left to dry for 2-3 weeks.

- After drying, the insulating mixture of sawdust and clay is again covered with waterproofing material, which is secured with a stapler to the floor joists.

- The last stage of insulating the attic floor is laying the finished floor.

Experienced craftsmen claim that the effectiveness of insulation depends on the quality of drying of the thermal insulating sawdust mixture. If possible, you need to dry it for 2-5 weeks. If you do not have that much time, it is better to use unmoistened mixtures.

Useful instructions

Today, there are a lot of thermal insulation materials that exceed sawdust in their thermal insulation properties and many other technical characteristics. But several advantages still sometimes push even a modern owner to follow in the footsteps of older generations and choose shavings for insulating the attic floor in a private house.

- Cheap

. Saving money is probably the most decisive factor when choosing sawdust, which has a very affordable price for a wide range of consumers. The same mineral wool will cost much more;

- Ecological cleanliness

. Wood in any form is highly environmentally friendly;

Despite the above, I still recommend that when purchasing sawdust, check with the seller for a quality certificate indicating their safety. After all, as I have already noted, they represent waste from production, which can be of a different nature and in some cases can result from increased toxicity of the chips.

- Ease of implementation

. Most of the time and effort will be spent on preparatory work, which can be divided into several stages, but the installation itself is very easy. We will pay special attention to all this further; - Durability

. Of course, this parameter directly depends on the quality of the insulation, but in any case, this method of thermal insulation will serve your family for a very long time.

Stage No. 1: selection

For insulating attic floors, not every shaving is equally good:

| Photo | Variety and comments |

| Fine sawdust . It has the highest thermal insulation properties, but is heavy and shatters greatly during use. | |

| Large chips . It is characterized by relatively weak insulating properties. | |

| Carpentry waste . They are easy to use and have fairly good thermal insulation qualities. Does not require additional drying. |

Stage No. 2: treatment with protective agents

Even if you choose coniferous carpentry waste, it won’t hurt to additionally impregnate them with protective mixtures. To do this, you can use a solution of copper sulfate or some other antiseptic.

After treatment with a protective composition, the material must be thoroughly dried.

Stage No. 3: preparing the base

Before insulating it with sawdust, the attic floor must be properly prepared:

| Photo | Description |

| We remove all debris, leaving the boards clean. | |

| We putty all the cracks and cracks, trying to achieve as monolithic a surface as possible. | |

| Cover the floor with plastic film. This is required in order to completely eliminate the possibility of wood dust entering the residential part of the house. |

Make sure that the film used has a sufficiently high vapor barrier. Otherwise, vapors accumulating under the ceiling of the residential part of the building will lead to the appearance of mold.

Stage No. 4: preparing the mixture

Insulation of a cold attic floor can be done either with dry sawdust or with mixtures mixed on its basis. The first option is less practical, since if it is implemented, the chips will sooner or later undergo shrinkage, which will lead to the loss of some of its thermal insulation qualities.

That is why special solutions are often prepared using the following algorithm:

- Sawdust is poured

onto a flat metal sheet. A large trough is also well suited for the implementation of the plan;

- Then add

one of the following ingredients:

| Photo | Preparation of the mixture |

| Gypsum with sawdust and fluff lime mixed in the following ratio:

| |

| Clay with sawdust mixed a little differently:

| |

| Cement can also be used as an additional ingredient when insulating an attic floor with sawdust. In this case, the following proportions are adhered to:

|

Instead of fluff lime, you can use lime dough, but you will need twice as much of it.

Stage No. 5: application

After all that has been done, all that remains is to lay the finished mixture on the prepared attic floor. This is not difficult for any home craftsman to do:

Using a shovel, spread

- Then compact

the applied mixture. If the attic is not intended to be used in any way, but at this stage the process of insulating its floor can be completed; - We lay boards on top of the thermal insulation

. This step is necessary if the attic will be visited. By protecting the insulation from people's feet, you will significantly extend its service life.

If you still decide to use dry sawdust without any additives, then you should adhere to two rules:

- Application is carried out

in two layers: the first - from large fractions, the second - from small fractions; - The top layer

of fine sawdust is carefully trampled down. At the same time, for better shrinkage it can even be moistened. The addition of ash or slag is also welcome.

Options for insulating a suspended ceiling

Due to the presence of wooden beams, a suspended ceiling is more rigid and durable, capable of withstanding significant loads. As a rule, false ceilings are constructed in bathhouses where there is an attic space.

This arrangement of the steam room ceiling makes it possible to use several materials for insulation. Most often, they use their own hands to insulate with sawdust, mineral wool and expanded clay. Let's consider these methods in more detail.

Application of expanded clay and mineral wool

Insulation of the false ceiling of a steam room with expanded clay and mineral wool occurs using the same technology, which consists of the following sequence of work:

- After the construction of the rafter system, the ceiling beams are hemmed from below with edged and planed boards.

- Then, from the attic side, a layer of foil vapor barrier is laid between the beams, foil side down.

- At the next stage, the space between the ceiling beams is filled with fine-grained expanded clay or filled with mineral wool.

- When filling with expanded clay with your own hands, you should leave a distance of 1–2 cm to the edge of the beams, a kind of air gap.

- The same technology is used when choosing the thickness of pressed mineral wool sheets.

- On top of the insulation is covered with a layer of waterproofing, which is thick polyethylene.

- Then plank flooring is laid along the beams from the attic side. In this way, the attic floor is formed and the insulation is covered.

There is an option in which the space between the beams is filled with sawdust as insulation. In this case, the technology of vapor and waterproofing remains unchanged. The main requirement for sawdust is that it must be absolutely dry. Otherwise, there is a risk of mold and mildew forming even before the bathhouse starts operating.

Advice! To reliably insulate a bathhouse with your own hands, you also need to insulate the space between the rafters on the attic side. For this, the same sheet materials are used - mineral wool and penoplex.

Folk way to insulate a ceiling

There are also folk methods for maintaining heat in a bathhouse for a long time. For example, insulate the ceiling of a bathhouse with clay. This method is optimally used in conjunction with modern materials for insulating the steam room. The technology for using this method consists in the following sequence of work:

- The clay must be mixed with water until a homogeneous fatty mass is formed.

- Then 3 parts of sawdust are added to this mass and mixed thoroughly until smooth.

- Another layer of waterproofing is laid on the prepared and boarded ceiling from the attic side. It is on this that the viscous mass of clay and sawdust is placed.

- The clay is carefully leveled, especially in the corners and at the junction of the walls and the ceiling.

- The thickness of the layer should be at least 10 cm when insulation is installed between the beams. In the absence of additional insulation, the layer of clay with sawdust should be at least 20 cm.

- During the drying process, cracks may appear in the clay layer. They must be sealed with a similar composition.

- After complete drying (about 1-2 weeks), the clay must be filled in. Sawdust, straw or wood shavings are suitable for this.

Advice! When insulating the ceiling, it is necessary to pay special attention to the chimney pipe. Around it you need to build formwork, which is filled with non-combustible material. For this purpose, filling with expanded clay, clay or asbestos is most often used.

The considered methods allow you to easily insulate the ceiling in a bathhouse with your own hands. Compliance with the described technology will allow you to quickly heat the bathhouse and retain all the heat and steam in it for a long time, which will allow you to enjoy the steam room and relaxation to the fullest.