Advantages of using oil for baths and saunas in finishing

- Dirt-water-repellent properties. Polymerizing deep in the wood, the oil reliably seals the soft fibers, preventing moisture and dirt, cosmetics and detergents from getting inside.

- Antiseptic properties. The special composition of the mixture of oils and waxes, as well as the use of biocides, prevents the development of microbes and mold inside the wood.

- Environmental friendliness. Vegetable oils and waxes do not emit toxic substances; they are used to impregnate wooden utensils and children's toys.

- Appearance and ease of application. Wood oil for baths and saunas does not form a film. The tactile sensations of the wooden surface are preserved. The coating highlights the grain of the wood. Oil can be applied with a brush, sponge or rag.

Impregnations and oils for steam rooms

Flaxseed oil is an inexpensive, safe, environmentally friendly and easy-to-use product that can protect wood in a bathhouse from the negative effects of high humidity and temperature.

Its mixtures with other components are successfully used for external impregnation of steam rooms. To protect and improve the performance characteristics of wood in a bathhouse, it is coated with antiseptic compounds. They also contribute to the long-term preservation of the aesthetic appearance of the material. And if auxiliary rooms or the outer surface can be treated with chemicals, then only natural ingredients are used to impregnate the shelves, walls, floor and ceiling in the steam room itself. One of the most common is flaxseed oil.

The process of impregnating wood with this substance is called glazing. Its main advantages are:

- Environmental friendliness. Flax oil does not emit toxic substances and is even used to impregnate wooden utensils.

- Reliable protection. The composition is able to penetrate deeply into the structure of the tree.

- Hydrophobicity. Effective moisture rejection.

- Maintaining appearance. The transparent coating preserves the grain of the wood and prevents it from rotting and darkening.

- Antiseptic effect. Flaxseed oil protects the surface from the effects of fungus and mold.

- Convenient application. Processing is possible even in hard-to-reach places.

- Relatively cheap. Compared to special impregnations for baths from leading manufacturers, the composition has a low cost.

As for the disadvantages of the substance, the drying time is highlighted. After final impregnation, you need to wait a few weeks, only then can you use the steam room.

Flaxseed oil is used both in its pure form and mixed with wax, tar, and turpentine to improve its performance properties.

A mixture with various components is usually used for external impregnation. This is due to the fact that turpentine, for example, is toxic and can cause allergies or cause thermal burns. Tar is less toxic, but has the same disadvantages as turpentine. Beeswax is the only substance a mixture with which can be used for internal impregnation of a bath.

Choose flaxseed oil, which contains the maximum glycerides of linolenic and linoleic acids. It polymerizes faster and has improved protective properties. Please note that pure flaxseed oil should be stored in a tightly sealed container and in the refrigerator.

You can buy natural oil at any pharmacy. Its price starts from 50 rubles per 100 grams. Calculate the required amount according to the principle: 1 liter of oil – per 10 m2.

Industrial bath impregnations based on it additionally include natural resins and pine turpentine. Compositions based on linseed oil from manufacturers Caparol, Rustins, Tikkurila, Remmers are popular. Price - from 300 rubles per liter.

Flaxseed oil is suitable not only for treating bathhouse shelves, but also for the entire room. In this case, it is advisable to impregnate the floor 3-4 times a year, since it is most susceptible to moisture. The remaining elements also need regular processing. Especially the ceiling, because high temperature affects it the most.

When choosing how to treat a wooden floor or staircase, the environmental friendliness and protective properties of the impregnation are first taken into account. Impregnating wood with natural linseed oil has a number of advantages:

- The old product acquires an aesthetic appearance, as small cracks, abrasions and unevenness are masked.

- Absorbing into the porous surface, the composition gives it water-repellent properties.

- After drying, dust and dirt adhere less to the surface.

- Emphasizes the natural texture of wood.

- The oil has antiseptic properties and protects the surface from fungi, mold and blue stains.

- It is deeply absorbed into the wood and will last at least 50 years.

- Protects wood from cracking and drying out.

- Wood never stops “breathing”.

- Hypoallergenic and suitable as finishing in children's rooms and kitchens.

Linen is used to coat any wood products: in the processing of houses, when finishing furniture and decorative elements made of oak, teak, pine, spruce, fir. Due to its composition, the oil is easily combined with various tinting emulsions. Apply independently as finishing and protection or under further varnish coating.

| Manufacturer | Name | Price for 10 l, rub. |

| Derufa (Russia) | Defura prof | 7 952 |

| Sigma Plus (Russia) | Linseed oil for wood | 6 650 |

| FireBioZashchita (Russia) | Solid linseed oil | 6 600 |

| Remmers (Germany) | Linen impregnation with wax | 11 450 |

| Seven oils (Russia) | Solid linseed oil for wood | 7 230 |

Which wood oil to choose depends on your financial capabilities. An unrefined product from any manufacturer is suitable for wood processing. Imported flax compositions are more expensive, but have additives in the form of beeswax or artificial polymers. They reduce drying time and simplify work. Each manufacturer has its own consumption and depends on the thickness of the product.

To tint the surface, impregnation with colors is purchased. This can be found in the catalogs of the manufacturer Tikkuril, price from 750 rubles/liter. Translucent tinting with various natural shades. Using colored oil, you can tint an inexpensive type of wood, such as pine, or give the appearance of oak or mahogany. After processing, it will be difficult at first glance to distinguish inexpensive material from a similar premium class one.

Most bathhouse fans agree that there is no need to cover the lining inside the steam room with anything. But if there is such a need, then you can use natural oils and wax. Some experts advise soaking the boards in linseed oil, to which you can add natural aromatic oils of your choice. You can use hemp oil, and, the cheapest option, sunflower oil, but refined, with minimal odor.

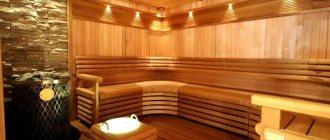

It is better to use natural materials to decorate the steam room

This treatment will create a greasy film on the surface of the wood and will not allow dirt to penetrate deep into the wood. But you need to be prepared for the fact that for some time, parts of the body from contact with the treated shelf will be greasy. After some time, the oil will be absorbed (or wiped off), but the protective film will remain.

Similarly, you can treat the steam room with melted natural wax. Before applying wax, the surface must be thoroughly sanded and only then apply melted wax.

There is quite a large selection of impregnations for industrial shelves. For example, the same Russian company Usadba has oil for shelves, and there is a similar composition for Eurotex-sauna. Of course, Tikkuril also has them - this is Supi Laudesuoja oil.

If you use the steam room correctly, ventilate and dry it on time, then fungi and bark beetles will not grow in it. They die at high and low temperatures:

- At a temperature of 70-80°C, spores of all fungi and protozoa die within 10 minutes.

- At -15°C, young shashal larvae die, and if the temperature remains below -15°C for a week, then adult larvae also die.

- A temperature of 60°C is the upper limit at which bark beetles can survive.

At high and low temperatures, fungi and pests die

If you either heat the bathhouse to high temperatures or freeze it, then it will not be afraid of any misfortunes, and you can deal with the remaining problems quite simply: clean it more often or cover the most used surfaces with natural compounds.

Features of internal oil treatment for baths and saunas

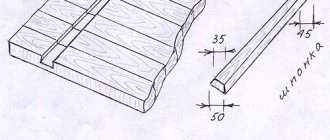

- Surface preparation. We carefully sand the wood with grit 120-150. If necessary, deresinate the surface with Martyanov turpentine. Remove dust using a vacuum cleaner. The pores should be open. The surface must be dry and clean. Do not use a damp cloth to remove dust from the surface.

- Stir the oil thoroughly. If necessary, we tint. If it is thick, you can heat the oil in a water bath to a temperature of t+50-60C. This will improve absorption and make the oil thinner.

- By carefully rubbing, apply a thin layer to the wood along the grain. There is no point in applying oil in a thick layer and flooding the surface. Oil is not paint. No matter how thick a layer of oil you apply, it will not absorb more than the wood can absorb. Applying too much oil will only worsen the polymerization.

- After approximately 20-30 minutes (depending on the specific wood), as soon as matte spots appear on the surface, this indicates that the wood has absorbed the required amount of oil. You need to carefully remove the oil from the surface with a lint-free rag or paper towel.

- After 12-24 hours at a room temperature of +22-25C, the oil will be completely dry to the touch and it will be possible to apply a second layer. When the temperature drops and tinting occurs, the drying time may increase. The second and subsequent layers are applied similarly to the first. Most often, 2 layers are enough.

How and with what to treat a log bathhouse - rules and methods of treatment

If you decide to use lining in a bathhouse as a finishing material, you need to know how to process this material even before starting work. Any wood is subject to the destructive effects of insects and moisture, it undergoes temperature changes, and therefore needs protection. Some experts believe that this issue needs to be addressed in a differentiated manner, which involves processing the material not in all rooms, but only in certain areas where the conditions are not so extreme. The main means for protecting wood include:

- varnishes;

- impregnation;

- antiseptics;

- flame retardants.

In practice today, drying oil and linseed oils are most often used, the latter of which prevent putrefactive formations. You can additionally resort to treating the surface with antiseptic agents, which, after drying, are covered with ship varnish.

Steam room protection

Many owners of country houses use lining in the bathhouse as wall decoration. In any case, you have to think about how to treat its surface after completion of the work. If you carry out this work, you will be able to extend the service life of the wood and make its structure resistant to destructive influences.

This protective acrylic varnish is used to treat the surface of wood in a steam room, as well as lining, which is installed in rooms with high humidity. If you wish, you can choose a tinted or colorless composition. The main advantages of this product are the formation of a water-repellent and dirt-repellent surface after the layer dries, which will retain its qualities even when exposed to temperatures of 120 °C.

Among other things, its ingredients include components that prevent the formation of mold on the treated surface. This varnish is universal, as it can be used on wooden and concrete surfaces. However, there is one drawback, which is expressed in the inability to use “Supi Saunusoy” as a covering for ceilings in a bathhouse.

Having installed the lining in the bathhouse, you must decide how to treat it, as this will protect the material and extend its life. Before applying the above composition, the surface is dried, the humidity should not be more than 75%. It is important to create suitable conditions - the temperature in the room should not be lower than 5 °C.

If you are thinking about the question of how you can treat the lining inside a bathhouse, you can pay attention to Supi Saunasoja, which is applied in two layers. It is advisable to ventilate the room. The first layer is diluted with water up to 20% if we are talking about a tinted composition. If you purchased a colorless mixture, then there is no need for dilution.

The second layer is applied without interruption; several boards should be processed at once, this will eliminate the difference in color. In order to find out what color the lining will have after drying, you need to test paint a separate board. You can begin caring for the lining after a month, when the wood is completely saturated with the protective agent.

If you are faced with the question of how to treat the lining in the steam room of a bathhouse, then you can purchase Interier Sauna, which is manufactured. This antiseptic is colorless and is made based on water and acrylic resin. It is intended for processing wooden elements of the room, the conditions of which are characterized by high humidity.

Before starting work, the surface is cleaned of dirt and wood shavings, after which the composition is mixed and applied in two layers using a roller or brush. The minimum humidity is 65%, while the optimal temperature is 20 °C. The second layer is applied after the previous one has dried, which will happen in about 3 hours.

If, when thinking about how to treat the lining inside the bathhouse, you chose the antiseptic described above, then its use should not be accompanied by the use of tools susceptible to rust, otherwise rust may appear on the surface over time. After applying the first layer, about an hour later, it is necessary to sand the surface using fine-grained sandpaper. This should have a positive effect on the final result. The described antiseptic is excellent for treating lining in the dressing room.

If you want to preserve the original structure and color of the wood, you can use Aqualak Eurotex Sauna. This is a colorless varnish that is made on the basis of water and wax. It is suitable for all types of ceilings, floors and walls. After completing the work process and the mixture has completely dried, you can apply wood paint, the color of which will remain unchanged.

The treated surface will not absorb moisture, which will have a positive effect on its service life. Among other things, the composition contains an antiseptic, which eliminates the occurrence of mold and mildew, as well as other microorganisms. You can be sure that the product is safe and environmentally friendly, it is not flammable and will not emit toxic fumes over time.

If you still can’t decide how to treat the lining in the bathhouse, then perhaps you should prefer Aqualak, which is applied to a dried and cleaned surface. If there is a protective varnish on the base, then the wood is sanded to prevent contact of the products with each other. After preparation, the first coat can be applied using a roller or brush, while the next coat can be applied after 40 minutes.

With an increase in the time between layers, the surface after an hour suggests the use of a different technology for applying the composition, which should be rubbed into the wood. You can start using the premises after three days, having previously heated the bathhouse. Repeated treatment may be necessary only after 4 years.

When using lining in a bathhouse as a cladding, you must decide how to treat it. As a comprehensive protection, you can use products called “Therma” and Prime. They will provide fire protection, give the walls antiseptic characteristics, and will resist corrosion processes, as well as the accumulation of moisture in the structure.

Sometimes it happens that the owners of country houses think about how to treat the lining in a bathhouse in a steam room when the wood is already contaminated. In this case, you can use products under the brand name “Nortex”. They are presented for sale in the form of “Bleach” and “Wood Doctor”. You can store this convenient container with a screw-on lid for several years until you need to re-process it.

Expert advice

You should not paint the lining in a bathhouse, since in a damp room the paint will prevent the wood from breathing, which will negatively affect the life of the material. If you decide to use aqualak, then applying it to a wet surface is excluded. The walls are pre-dried, only then can work begin. You should follow the manufacturer's recommendations, where you can find information about the permissible range of temperatures and humidity during work.

When the question arises about how best to treat the lining in a bathhouse, some try to apply an antiseptic to the varnish or paint coating. This cannot be done; the initial treatment is to remove old coatings.

Conclusion

If you are thinking about the question of whether it is necessary to process lining in a bathhouse, you should listen to the opinion of experts; some of them adhere to the rule that it is not worth processing lining in a bathhouse. However, this will make surface care more difficult. After each procedure, the room will need to be ventilated and dried, as well as cleaned of any dirt that has appeared.

Building a bathhouse is a complex process that includes many different tasks. The basis of the bathhouse is a log house, which is additionally lined inside. The lining most often used is lining made from alder, aspen or spruce, which have high strength and resistance to steam and moisture.

Visiting the bathhouse is an ancient tradition that has retained its relevance today due to its healing properties. Most often, bathhouses are built in suburban areas, installing a log house on the foundation.

When building a bathhouse, it is important to remember that the log house of the bathhouse needs additional protection, because inside it will be exposed to moisture, steam and high temperatures. Seasonal temperature changes and rains also harm the wood, so it is recommended to treat the outside of the log house as well. In this article we will tell you in detail how to treat the log house of a bathhouse outside and inside.

First of all, it’s worth talking about the types of special impregnations that you can easily find in construction stores.

Impregnations are of the following types:

- Antiseptic agents are created to protect wood from the negative effects of moisture, for example, fungus and mold (more details: “Fungus in the bathhouse - how to get rid of it once and for all”). Such pests occur when moisture lingers for a long time on the wood and in its pores, so antiseptic impregnations penetrate deep into the wood structure and harden, preventing moisture from entering;

- Next, it’s worth talking about how to treat the log house of a bathhouse in order to protect it from fire. In this case, fire retardants will help you, which can be used indoors and outdoors. Their non-flammable composition also penetrates the pores of the wood and protects it;

- Complex impregnations are universal: they prevent the formation of mold and mildew, protect against rotting and fire. Such compositions are used outside and inside the log house.

Operation of baths and saunas after oil treatment. What you need to know

Even though the oil dries to touch in 24 hours at room temperature, the oil inside the wood is still liquid. The process of drying the oil is called polymerization and can take 2-3 weeks. The rate of polymerization depends on the temperature and humidity in the room. If you start heating the steam room without waiting for the oil to polymerize, as it evaporates it will begin to emit a pungent smell of burnt oil or even smog. Before starting operation, after complete polymerization of the oil, it is necessary to make 3-4 full wet heating of the steam room. To care for the surface, we recommend wiping the wood with a rag moistened with a small amount of oil once every 5-6 months, depending on use.

What is the difference between wood oil for baths and saunas “Martyanov” and other oils

- Vacuum cooking. We cook oils in a vacuum at very high temperatures. Such oils have better protective properties compared to traditionally brewed oils. The hydrophobicity of our oils is an order of magnitude higher than usual, which is clearly demonstrated in this video, where oil for barrels and Martyanov fonts is tested.

- Complex composition. When buying oil to treat a bath or sauna, first of all you buy the contents. The cost of the oil, and ultimately the result, depends on what and how much the manufacturer puts in the jar. We use a whole mixture of vegetable oils and waxes, because the importance of each component is difficult to overestimate. By adding various types of oils and waxes to the composition, we do not save money, thereby significantly increasing the protective characteristics compared to traditional linseed oils. You can see the composition of wood oil for baths and saunas “Martyanov” in the section – Characteristics.

- Safety. Contact with the treated surface is absolutely safe for animals and plants. Despite the fact that our oils are 97-99% natural ingredients. From 1 to 3% are safe high-tech components that are used in expensive European oils. We have a GOST-R certificate of conformity, confirming the safety of surface contact with food, processing of children's furniture and toys. Before purchasing and using, we recommend that you carefully study the composition for individual intolerance to the components.