1622

A bathhouse is a room with a specific microclimate that has a beneficial effect on the development of pathogenic bacteria. The appearance of mold or mildew in rooms of this type is not uncommon, as they love humidity and warmth. Why this problem occurs and how to deal with it, we will consider in this article.

Wooden finishing of the interior of the bathhouse

Types of flooring for steam rooms

Steam room (steam room) is a bath room in which a high temperature is maintained. As a rule, the humidity in a steam room does not reach 50%, so the materials used in the room “suffer” more from the enormous temperature difference, which should be taken into account. What should be the arrangement of floors in the steam room?

To ensure minimal heat loss in the room, the base in the steam room of the bathhouse is raised 8-10 cm above the zero level. At the same time, in the washing room, on the contrary, the base is deliberately made below the zero level in order to prevent water from seeping into other rooms of the bathhouse.

So, what kind of floors can be made in a steam room? The first thing people pay attention to when choosing flooring materials is their physical and mechanical properties. The material must have the following qualities:

- resistance to temperature changes;

- low hygroscopicity;

- resistance to rotting;

- wear resistance.

The following types of floors can be made in a steam room:

- Wooden is an environmentally friendly coating that has good heat-insulating properties. But such material has fairly high water absorption rates, so it requires special treatment with varnishes and antiseptics;

- Concrete is a wear-resistant and durable coating that is not afraid of exposure to temperatures. However, it is advisable to insulate such a floor, since it contributes to large heat losses in the steam room;

- Tile coating is a coating that has excellent wear resistance. But tile, like concrete, is a very cold material. Therefore, before laying it, it is advisable to insulate the subfloor.

To understand how to make floors with your own hands in a steam bath, let’s look at each of the options in more detail.

Treatment of walls and ceilings of a bathhouse - with what and how?

Special attention should be paid to the arrangement of an object such as a bathhouse or steam room. The room must be resistant to high humidity and temperature changes. Traditionally, deciduous trees are used for the construction of baths, as they have a number of advantages:

- low thermal conductivity;

- environmental friendliness;

- beautiful appearance;

- nice atmosphere.

To improve your health and find peace of mind, you need a pleasant atmosphere close to natural conditions. Natural wood has everything necessary and gives a person its energy, natural warmth, and health. Wood is superior in its technical characteristics to many modern materials. The only drawback of natural material is that it cannot retain its natural qualities for a long time without special processing.

In the old days, people used simple means for processing - oil or wax. Of the inexpensive oils, we used sunflower oil without a specific odor. More expensive oils were also used - anise, lavender, rose. Some expensive oils were added to refined oil and a richer and more pleasant smell was obtained.

If you use special antiseptic drugs, then the risk of bacterial infection is reduced. The internal surface of the bathhouse receives protection from various types of wood-destroying parasites.

To make the right choice among protective compounds for treating baths and saunas, it is advisable to understand their properties. This is not difficult if you carefully read the manufacturer's instructions.

For example, the water-borne antiseptic “Sauna” (“Senezh”) on an acrylate base forms a transparent, breathable, dirt- and water-repellent heat-resistant polymer coating on wooden surfaces.

It not only protects wood from biological damage, but also has an antimicrobial effect—it destroys household pathogenic microorganisms that cause infectious diseases in humans.

The water-based Sauna product will help preserve the wooden ceiling and wall panels of the steam room for a long time and at the same time make them more decorative.

Natura (Teknos). The initially colorless composition does not change the tone of the wood, but it can be easily tinted to any shade you like using the Teknomix system. The translucent coating will leave the natural pattern of wood fibers visible and at the same time enliven the interior.

By the way, the use of a tinted composition will help non-professionals distinguish treated surfaces from untreated ones.

An unusual, spectacular shine, along with water and dirt-repellent properties, will be given to wooden walls and ceilings by applying the pearlescent acrylate protective composition Supi Arctic (Tikkurila). If desired, it can also be tinted according to the Arctic color catalog.

Options for installing floors in bathhouses and steam rooms

What material should I use to make a warm wooden floor in a steam room? Wooden floors are highly hygroscopic, which accelerates the process of warping and rotting. However, larch is one of the materials that have minimal water absorption. The structure of larch contains many resins and phytoncides that prevent the wood from getting wet and decomposing under the influence of fungus.

How to arrange a wooden floor with your own hands?

- Preparing the base:

- First of all, larch logs are installed, after which the board will be laid on the wooden sheathing;

- Skull bars are attached to the bottom of the beams;

- Then the rough boards are laid.

- Hydro- and thermal insulation:

- A waterproofing agent (glassine or roofing felt) is laid on top of the boards;

- The joints between the sheets of waterproofing are coated with a mask for better sealing;

- To insulate the base, lay a layer of thermal insulation (foam plastic, polystyrene).

- Installation of tongue and groove boards:

- A leak-proof floor is made in the steam room, so tongue-and-groove boards with a locking system are laid without any gaps;

- A technological gap of 3 cm is left between the boards and the walls;

- The flooring material is attached to the joists with self-tapping screws;

- After this, the wooden floor is varnished in several layers.

Choice of varnish and paint

Wooden floors in a bathhouse can be varnished, but not all varieties are suitable for finishing. You can only use non-toxic, safe compounds that do not emit substances harmful and hazardous to human health when heated. The application of varnish is carried out only after careful preparation of the wooden surface: cleaning it, sanding, filling, removing and treating mold-damaged areas with an antiseptic.

When choosing paint, you should take into account the characteristics of the composition. Some of them cannot be used in a steam room, but can be used in other rooms.

Table. Types of paints

| Paint type | Description | What rooms is it suitable for? |

| Water-based | Natural base. Short service life (no more than 3 years). | All premises |

| Acrylic dispersion | Dries quickly. Large selection of shades. | All premises |

| Alkyd | Dims when heated. | Not recommended for painting the floor in a steam room. |

| Silicate | Has excellent water resistance | All premises. |

| Oily | Not resistant to high temperatures. Dims when heated. | Not recommended for washing and steam rooms. Suitable for painting the floor in the dressing room, rest room. |

What should you consider when choosing?

Modern manufacturers offer many different products for wood processing. Before choosing an impregnation, you should identify the purpose of its use:

- painting object;

- preservation of natural texture, tinting or painting;

- level of moisture resistance of the room;

- applying the product to the surface.

Impregnation for wood must have many qualities, the main thing is to provide the material with reliable protection and not reduce its ability to pass air. When decorating the interior of a room, the environmental friendliness of the product is very important. This quality is especially important if there is high humidity indoors. Such conditions will provoke the release of harmful impregnation components.

There are special requirements for wood impregnations. After coating the surface, there should be no film left on it. When the temperature in the bath increases, the coating should not release components harmful to health.

Concrete base in the steam room

The installation of a concrete base in a Russian bathhouse guarantees twice the service life of floors compared to wooden materials. What is needed to install a concrete base? Concrete is a material with high thermal conductivity, so in the process of pouring it, insulating the base will be an obligatory step.

To increase the service life, the surface of concrete floors must be painted with a dust-removing compound.

To do all the necessary work correctly, you need to take into account the following nuances:

- When installing concrete floors in a bathhouse built on a strip foundation, the soil under the steam room is compacted;

- Then a mineral cushion of sand, crushed stone and gravel is laid;

- Next, the first layer of cement mortar is poured onto a well-compacted base;

- After the screed has hardened, fine-grained expanded clay is poured onto the base as insulation with a thickness of 100 mm;

- To make the subfloor more durable, a reinforcing mesh made of rods with a diameter of 8 mm or more is mounted on the expanded clay;

- Then pour the second layer of cement composition with your own hands and wait until it dries completely.

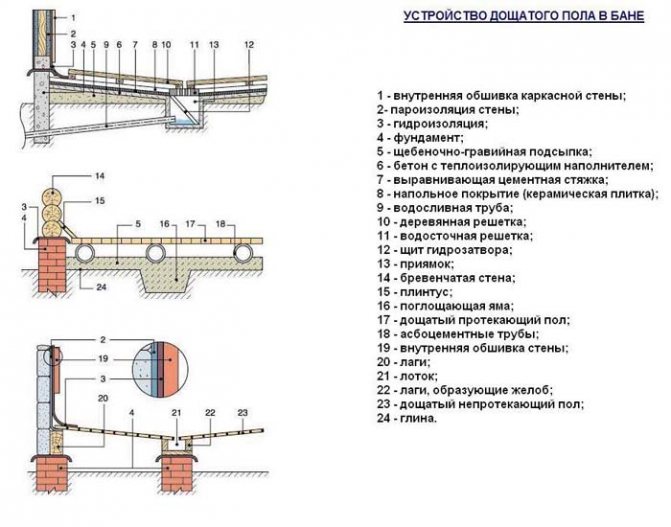

How to make a floor in a bathhouse

Traditionally, the floor structure in a bathhouse is a plank flooring laid on logs. The material used is spruce, pine, larch and fir wood. These are moisture-resistant durable woods with a natural antiseptic in their composition. One of the advantages is that when wet, floors made from these types of wood do not slip, which is not the case with oak planks.

When installing a wooden floor, its design is of great importance. The floor can be poured or not leaky. In the first case, the boardwalk is installed with gaps between the slats through which water flows freely. In the second case, water flows into the sewer through a special hole in the floor.

Note! All wooden elements in the bathhouse must be treated with antiseptic compounds.

Concrete floor with drain and plank drainage on top

Concrete floors are strong and durable. At the same time, when pouring the screed, it is necessary to insulate it. The screed is mounted with a slope towards the drain hole.

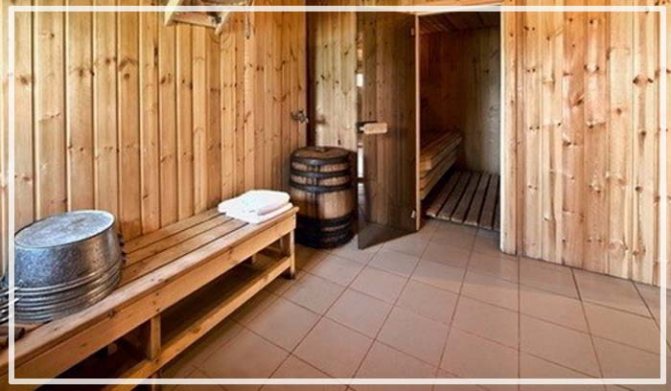

Practical modern materials for arranging the floor in a bathhouse are ceramic tiles and stone. This is a waterproof, durable material. The disadvantage is the cold surface. Therefore, a portable pourable boardwalk is laid on the floor, which can be taken out of the room to ventilate and dry.

Tiles on the floor in the steam room

Recommendations for use

All impregnations are produced on a chemical or organic basis. Any of the varieties has a water-repellent effect. Most often they are universal means for coating wooden surfaces:

- protection from moisture and high temperature;

- resistance to damage by fungal life forms and harmful insects.

In terms of their composition, they can be water-soluble or oil-soluble. There are also combined impregnations in the form of paints and varnishes that have protective effects against moisture and harmful microorganisms. Many of them have additional qualities - fire resistance and dirt-repellent properties.

Antiseptic impregnations contain toxic substances and are therefore considered aggressive chemicals. When using them, you must follow the instructions for use.

To keep wood in good condition, it is recommended to treat it with protective agents at least once every 2 years. The best time for processing is considered to be autumn. In the spring season, the movement of tree sap begins. They provoke the formation of rot, so it is very important to process the wood in a timely manner in order to maintain the integrity of the structure and protect it from rot.

It is recommended to apply antiseptics only to new wood before using the bathhouse or steam room. The old surface must be cleaned of coating (paint, varnish), as well as dirt and dust. After this, apply the composition using a soft wide brush or roller. When everything is completely dry, you can use the bathhouse.

If you approach the issue of coating a wood surface correctly and apply impregnation correctly, you can preserve it for many years and enjoy a steam bath with health benefits.

So, if you have decided how to treat wooden floors in a bathhouse, it’s time to find out exactly how it’s done. There is one important nuance here - floor treatment products are not suitable for walls and ceilings and vice versa. Experts recommend a solution called Tikkurila Supi Laudesuoya from a well-known Finnish manufacturer.

The baths themselves are different - summer temporary huts with a pouring floor, solid all-season buildings made of wood, brick, foam blocks or frame. But in general, we can say that the floors can be either wooden or concrete (in the steam room, provided that gratings are installed).

Concrete floors are often turned into tiles in steam rooms and sinks, and they don't need painting, so we won't cover them in this article.

Wood

Causes of wood rotting in a bathhouse

Without the use of special means, even moisture-resistant wood will begin to rot. The combination of humidity and high temperature creates a comfortable environment for the proliferation of pathogenic organisms. Another reason for wood rot is the lack of high-quality waterproofing and ventilation in the room.

Currently reading:

Gas hoses for gas stoves: which hose is better...

How to calculate the number of rolls of wallpaper when...

How much does it cost to add siding to a house?

Mineral wool or basalt wool? What's best for...

When choosing a material for a bath, you should take into account in advance that coniferous wood, which contains phytoncides, is highly resistant to the formation of mold and mildew on their surface. Therefore, fir, cedar, pine, spruce, and larch are used for flooring.

Impregnations for treating wood in a bathhouse must have the following list of properties:

- Water repellent. This quality makes it possible to create a moisture barrier on the surface of the wood and prevent it from penetrating deep into the wood structure.

- Antiseptic. These are substances that inhibit the growth and reproduction of pathogenic microorganisms in the structure of wood.

- Biological. The tree often suffers from insect pests, so the protective composition should repel them.

Note! Less stable materials are birch, alder, elm, maple, aspen, and linden. Therefore, treating wood with special compounds is a prerequisite.

Fungal infection of the floor structure

Tile covering

Tile floors are the optimal solution for tiling the rough base in a Russian bathhouse. This material has all the necessary physical and mechanical properties that provide the coating with a long service life:

- non-hygroscopic;

- resistance to temperature fluctuations;

- resistance to rotting;

- wear resistance.

The technology for installing tiles in a Russian bathhouse is practically no different from tiling in other types of premises. The only thing that should be taken into account when laying tiles is the quality of the adhesive composition. The material must stoically withstand large temperature fluctuations, so it is desirable that it have the following characteristics:

- high adhesion to concrete surfaces;

- good heat and moisture resistance;

- elasticity and wear resistance.

Features of painting for different coatings

Finally, we’ll talk not about what you can use to paint the floors in a bathhouse, but about how to do it correctly, because different compositions require different brushes.

If you decide to use oil (not oil paint, but floor oil), then the brush you use to apply it should be made of natural bristles. Due to its structure, such a brush will not leave streaks on the surface of the wood. By the way, you can only remove oil from it with a solvent.

Wood glaze is applied with a brush with mixed bristles. Wash off with water.

Colored wax requires a brush made of artificial fibers for application. It is liquid, so you can use a roller or a spray gun.

In general, there is such a division: water-based paints and varnishes are applied with artificial brushes, and other varnishes and oils are applied with natural bristles.

All water-soluble antiseptics are made on an acrylate base. This composition has a complex effect on wood in the form of protection from harmful influences:

- moisture;

- biological damage;

- pollution.

The disadvantage of such compositions is the rapid leaching from the structure of the wooden coating. For this reason, it is necessary to coat the surface more often than with other products. To preserve the properties of the impregnation, it is advisable to cover the surface with additional protection in the form of a thin layer of waterproofing.

The advantages of water-soluble compositions are the inability of the products to affect the color of the surface, its texture and the absence of an unpleasant odor. This product can be purchased commercially in the form of a dry mixture or solution.

Oil-based impregnation penetrates deeply into the surface of the wood. Wood-protective oil retains the properties of wood for a long time, despite frequent wetting of the surface. This oil contains an unpleasant and pungent odor. This is the only negative.

Due to the high toxicity of the preparations, many of them are not recommended for impregnation of wooden surfaces indoors. However, subject to safety precautions, certain types of oil can be used to treat baths. Impregnations based on wax and oils tend to compact the material. This allows the wood to retain its natural qualities for a long time and give the structure wear resistance and strength.

Alkyd-oil based impregnations give a good effect. With their help, the hygroscopicity of the material is preserved, deformation and cracking of wood is prevented. After oil treatment, the wooden surface acquires good decorative qualities. Many of these products are easily absorbed and are colorless primers.

Oil-wax is suitable for treating various surfaces inside and outside, although its quality is inferior to synthetic products.

Experts recommend ventilating the bathhouse or steam room more often. If this is done regularly, the level of humidity in the room decreases and then the protective layer helps to extend the durability of the wooden covering.

The main distinguishing feature of water-soluble impregnations is the base on which they are made - acrylic. An additional component of the product is usually a special coloring color, which gives the treated sauna lining a certain shade. Acrylic impregnations with varnish are now very popular. They are used to treat baths inside and outside.

Despite the many positive characteristics of acrylic preparations, they have one drawback - gradual leaching from the wood structure. To maintain the natural cladding, it is necessary to carry out regular treatments. An excellent solution to this problem would be to first coat the surface with a waterproofing solution and then with bath impregnation. With such an integrated approach, the wood will last much longer.

Due to the absence of color and odor in acrylic, such preparations are especially suitable for interior work. This is a good option for those owners of baths and saunas who want to preserve the natural wood grain. On sale, water-soluble products are presented in the form of dry mixtures or ready-to-use solutions.

Oil impregnations are distinguished by their ability to penetrate deeply into the wood base, leaving a thin film on the outside. They are characterized by durability and can maintain their performance much longer, even at excessive levels of humidity, than water-soluble preparations.

Oil impregnations are characterized by a high degree of toxicity and the presence of an unpleasant, pungent odor, since they contain a solvent. Due to their toxicity, it is not recommended to use these substances indoors without following safety regulations. They can be used to treat the dressing room, outside walls, and utility rooms.

Laying tiles on the floor in a bathhouse

In modern baths, you can increasingly find tiles on the floor. And not only in the relaxation room and washing room, but also in the steam room. Tile is a universal finishing material. It is not afraid of temperature changes and water; the tiles are easy to care for and can be regularly treated with disinfectants. It doesn't rot or burn. And the variety of shades, patterns, shapes and sizes allows you to realize any design idea. In addition, tiles go well with natural wood.

Gratings over ceramic tile floors

Tiles for laying on the floor of a bathhouse have the following advantages:

- This is an environmentally friendly material made from natural ingredients that does not emit harmful substances or smell.

- The tiles are absolutely not afraid of water, in any quantity. Its structure ensures minimal hygroscopicity.

- The tiles are easy to care for and do not absorb odors or dirt.

- The tiles are not afraid of temperature changes, hot steam, or condensation.

- The material does not rot and is not destroyed by insect pests.

- It can imitate any materials and is available in a wide range of colors, shapes and sizes.

- The tiles are compatible with underfloor heating systems. In a bathhouse, especially in a washing room and steam room, to ensure tactile comfort, it would be a good idea to organize a water-heated floor powered by a stove.

- When laying tiles, it is not difficult to make the necessary slope to drain water into the drain hole.

Preparation and styling

The base for laying tiles can be wooden or concrete. The second option is more preferable. The concrete floor is also moisture resistant and does not rot. Before pouring the screed, it is necessary to install a drainage system and a drainage system. It is better to locate the drain hole in an area with less traffic. The material of the drain hole located on the floor surface should not overheat under the influence of high temperatures.

When the concrete base gains strength, tiles can be laid. The process occurs in the same way as in residential premises. However, on the floor in the bathhouse it is necessary to provide a slope towards the drain. The process of laying tiles is as follows.

Table. Instructions for laying tiles

| Illustration | Description |

| Step 1 | The concrete base is checked for evenness - it should not have defects on its surface. It is immediately worth noting that the slope can be formed by a screed or during installation using an adhesive solution. The concrete is cleaned of dust and degreased. Then the markings are applied, using as a sample the laying diagram previously drawn on a piece of paper to scale. The trimmed tile elements should be in invisible areas (in corners, under shelves). |

| Step 2 | Tiles are laid along the first marking line. Spacer plastic crosses are immediately placed between the tiles. This will allow you to draw a second marking line, which will run at an angle of 90 degrees to the first. Laying the tiles will begin from the intersection point. |

| Step 3 | Prepare an adhesive solution. The adhesive for laying tiles in a bathhouse must be elastic, since it will regularly be exposed to temperature changes. Instructions for preparing the adhesive composition are indicated by the manufacturer on the packaging. It is produced in the form of a dry mixture, which must be diluted in a certain proportion with water and mixed until smooth using a construction mixer. |

| Step 4 | The finished solution is applied to the area where the first tile is laid, slightly extending beyond the boundaries of the marking. Level the composition with a notched trowel. |

| Step 5 | When laying large-format tiles with one side larger than 300 mm, the adhesive composition is applied to the back side. Laying large tiles is preferable, since the coating ultimately has fewer seams. |

| Step 6 | The tile is laid, checking its position in the plane. The quality of the subsequent floor covering depends on the correct installation of the first element. |

| Step 7 | To adjust the position of the tile, tap it with a rubber hammer. This must be done through a layer of thick cardboard or thin plywood so as not to damage the material. |

| Step 8 | During the process of laying the tiles, a joint is formed between the tiles using plastic spacer crosses. |

| Step 9 | A day later, when the glue has dried, the crosses are removed and the joints are grouted. The grout can be epoxy or cement. The first one requires skill, as it picks up quickly. The grout is spread over the seams using a grater. Then (after 10 minutes) the excess is removed with a damp sponge. After 40-50 minutes, wipe the tiles. If there is a white coating, then a special product is used to remove it. |

If porcelain stoneware is used as a floor covering, then special attention should be paid to the adhesive solution, which should have not only high elasticity, but also adhesion.

Video - Laying floor tiles in a bathhouse

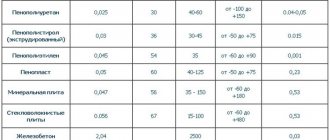

Types of insulation

The competent choice of heat insulator for wooden and concrete floors deserves special attention. Due to the specific microclimate in the steam room, it is undesirable to use mineral insulation. This is due to several reasons:

- When wet, the thermal conductivity of the insulator increases;

- Damp mineral insulation is an ideal substrate for the development of pathogens: mold or mildew.

. Having decided to insulate floors with your own hands, it is advisable to choose the following heat insulators:

- Perlite is a lightweight material with minimal thermal conductivity, which is added to cement mortars to reduce the thermal conductivity of the screed;

- Expanded polystyrene is a non-hygroscopic insulation material that can be used to insulate both wooden and concrete bases;

- Polystyrene foam is a thermal insulating material that is similar in its technical characteristics to expanded polystyrene.

Antiseptics and varnishes

Is it necessary to use additional products to treat floors in a Russian bath? Larch boards are practically not biodegradable, but during its operation, resinous substances can be washed out. Over time, this leads to the development of mold on the coating. To make wooden materials less susceptible to pathogens, antiseptics are used:

- With organic solvents – they give the coating greater moisture resistance and strength;

- With oil components - ideal for steam rooms in which temperature changes are often observed;

- Combined - help protect wood from both fire and rot.

In order to reduce the hygroscopicity of a wooden coating, it must be painted with varnish. Special compounds with water-repellent properties form a protective film on the surface of the wood, which prevents getting wet and, accordingly, the development of fungus.

How to apply antiseptics correctly

Before treating the floor in a bathhouse, it is necessary to sand it in order to remove the damaged outer layer and increase the absorbency of the wood. The floor must be dry and clean before treatment.

Important! The manufacturer indicates recommendations for working with a particular composition on the packaging.

Apply impregnation in several layers. Each subsequent layer is applied to the completely dried previous one. The air temperature in the room should not be lower than +5 degrees.

Impregnation of wood with antiseptic

If the tree is already affected by mold, then you must first take measures to eliminate it by treating it with special antiseptic compounds or replacing the boards with new ones.

Most often, when building a bathhouse, wood is chosen as the wall material. The log house looks aesthetically pleasing and does not require additional finishing outside and inside. However, the walls will need to be periodically treated with protective compounds. And many people have a question: how to treat the outside of a bathhouse? We will talk about this in a special article.

How and with what to treat lining in a steam room - practical tips

Building a bathhouse is a complex process that includes many different tasks. The basis of the bathhouse is a log house, which is additionally lined inside. The lining most often used is lining made from alder, aspen or spruce, which have high strength and resistance to steam and moisture.

To extend the service life of wood, it is recommended to treat surfaces with protective impregnation at least once every two years. It is better to plan these works for the autumn. You need to choose the impregnation that is marked that it is intended for use in bath conditions (appropriate temperature, humidity).

An antiseptic for a bath should be applied exclusively to a cleaned surface. From the wood, you first need to clean off the old varnish, paint (if there was any), damaged layers, sweep away the dust, and then apply the product only with a soft and wide brush. To prepare the surface, it is most convenient to use a grinding machine.

To add a tint to the protective impregnation, you can add a little dye. The lower crown of the bathhouse frame is best treated with a bitumen-based composition; it perfectly protects against rotting.

The foundation must be protected with waterproofing, otherwise it will begin to rot over time. It is advisable to cover surfaces that will most often come into contact with water with several layers of impregnation. You can use the bath only after the composition used has completely dried.

Briefly about lining coating

When thinking about how to process wood in a bathhouse, you first need to prepare the necessary tools and buy additional materials:

- Solvent;

- Stirring brush;

- Roller;

- It is recommended to purchase a spray gun, but you can apply the varnish in other ways;

- Sponge;

- Paint tray;

- Protective equipment (respirator, goggles, gloves and overalls).

It is important to remember that the impregnation of the sheathing must be carried out strictly before its installation. It is also necessary to process the sheathing on which the lining will be attached. After the impregnation has dried, you can sheathe the room.

Having completed the installation work, it is necessary to process the wood again. It is important to note that it is important to carry out such treatment approximately once every 2 years, because the coating on the wood takes the “blow” and wears out, keeping the wood in the bath.

Proper processing of lining

Having decided how to cover the lining in the steam room of the bathhouse, you can proceed to the processing itself. To perform high-quality impregnation that will last a long time, we recommend that you read the following instructions:

- Processing lining in a steam room begins with preparing the wood itself. Clean it from various contaminants with sandpaper or other suitable method. It is also recommended to wash the boards with an aqueous solution of soda (300 g of soda per 10 liters of water);

- Next, you need to degrease the surfaces. Remember that not only the lining itself is impregnated, but also the frame to which it is attached;

- Sand surfaces with pumice to obtain a smooth finish;

- Next, you need to apply an antiseptic that will protect the wood from fungus and mold;

- Now you can saturate the paneling. When choosing impregnation for the dressing room, pay attention to the humidity of the air in it, as well as the temperature of the steam. If the indicators are approximately equal to the indicators inside the steam room, then it is necessary to use the same impregnation.

By doing all the work correctly, you can achieve an excellent result, as in the photo.

Bath cover care

Now you know how to treat the lining in a steam bath, but such treatment will not be able to completely protect your bath, so you will have to monitor the room, following some rules:

- Always ventilate the area to minimize the chance of mold or mildew forming;

- The room must be washed frequently with a wet cloth, without using chemical detergents;

If serious contamination appears on the surface of the wood, or it has darkened, then use sandpaper. You can also use special bleaches for wood, but under no circumstances use bleach solutions, because when heated they release a huge amount of toxins, and they can even leave a burn on the skin.

Causes of mold and mildew

Wood is an organic environment for the development of pathogenic microorganisms, the development of which requires moisture and heat. The bathhouse is a source for their development, since the surface is finished with wood, and inside there is enough moisture and heat for the spread of mold, rot or fungus.

If left untreated, the joists and the rest of the cladding wood will rot and become unusable over time. The main reasons why decay occurs:

- lack of processing or it is performed poorly;

- violation of technology during the construction of a bathhouse and carrying out incorrect waterproofing measures;

- lack of high-quality ventilation, which ensures constant humidity in the room;

- constant room humidity.

Rotten damage to beams

Important! Some types of wood are resistant to the development of pathogenic microorganisms.

Thus, coniferous species contain resins, which contain phytoncides, which provide immunity to the appearance of mold or mildew. Therefore, to finish the floors in the bathhouse, it is recommended to use:

- pine;

- cedar;

- spruce;

- fir;

- larch.

Features of larch. When wet, this rock becomes much stronger and harder, and it contains special resins that prevent the formation of mold, rot and mildew.

Species such as maple, alder, birch, aspen, linden and ash are most susceptible to these microorganisms.

But in order to preserve the floor for as long as possible, it is necessary to treat it with special substances.

Compositions for bath treatment (internal)

When building a bathhouse with our own hands, we rarely resort to any protective compounds for its internal treatment, even with a minimum amount of chemicals, and this, in fact, is justified in many cases.

However, untreated lining on the walls, and even more so on the shelves and benches in the bathhouse, quickly get dragged and covered with dirt, especially if you have many annoying relatives for whom the firebox of the bathhouse is always a reason to come to you. In this case, the premises of a steam room, sauna, etc. will very quickly look like a “black bath”.

Other reasons why a bathhouse needs to be treated with protective compounds are not only darkening of the lining, but also its cracking, mold and mildew, and of course, “warping” of the board, which is very difficult to avoid. These modern bath treatment compounds are completely environmentally friendly and harmless to health, can easily withstand high temperatures, and they have no equal in protecting against dirt.

The premises of the Russian bath and Finnish sauna are traditionally decorated with wood. Most often, lining made of hardwood (linden, aspen, alder, birch) is used for this, the wood of which is characterized by low density and, therefore, low thermal conductivity.

When the temperature in the steam room increases, it does not heat up very much and does not burn the skin. Finishing materials made from coniferous trees (pine, spruce) are rarely used for the interior of saunas and baths, since when heated they release resin, which burns and stains the skin.

Steam room is a room with extreme conditions.

Its wooden cladding is subjected to regular and intense exposure to high temperature and humidity. This entails such negative consequences as warping, cracking, darkening of the boards, and the formation of mold and mildew on them.

It is obvious to many that wooden surfaces cannot be left without special protection. But another judgment is no less common: a properly built and operated bathhouse does not require additional treatment of ceilings, walls, floors and shelves.

Both points of view have a right to exist.

For those who have the opportunity to change the finish of the steam room every 2-3 years, it hardly makes sense to treat wooden surfaces with anything. The same applies to extremely careful fans of dry steam, and to those who rarely relax in this way.

But for hunters to take a steam bath in a large group, with birch brooms and aromatic oil, experts still recommend taking care of extending the life of the natural material.

Moreover, specialized protective compounds are present in the range of many paint manufacturers, for example Akzo Nobel (Dulux brand), Belinka, Tikkurila, Teknos, Rogneda, Senezh, Empils.

Please note that all compositions for baths and saunas offered on the domestic market can be divided into two groups:

- for processing wooden cladding of bathhouse ceilings

- for treating walls (more numerous) and for impregnating shelves (shelves), benches and other bath elements that are in direct contact with the naked body.

There is a recipe for homemade wax impregnation, which includes beeswax and linseed oil, the ingredients are taken in equal proportions. The grated wax is melted in a water bath, and then it is mixed with the second component and allowed to cool.

It is recommended to use harmless protective materials to impregnate the walls of the steam room. The use of oils allows you to create a greasy film on the surface of a wooden structure and protect the wood itself from penetration deep into dirt. There is one minus here. For some time after contact with the treated surfaces, a greasy film will be felt, but soon the oil will be absorbed and partially erased, leaving only a protective film.

A good result is obtained after using melted natural wax. This impregnation is easy to do with your own hands. But the surface must first be thoroughly cleaned, degreased and only then wax applied.

Now to the main question - how to destroy fungus in a bathhouse?

If the bathhouse does not have a constantly functioning heating system, then it is at risk. First of all, this applies to wooden baths. And then such “beauty” blooms on the tree.

Fungus on timber

Fungus in the shower

The fungus has no particular preference; it can be on the wall or on the floor and ceiling - where there will be more dampness. For example, if the corners of a bathhouse are not insulated as required, it will “bloom” there. The white house mushroom can appear where you don't expect it at all. Sometimes it happens…

If the lesion is already noticeable, do the following:

Mechanical cleaning

Depending on the depth of the damage and the type of material, a spatula, sandpaper, iron brush, drill with a brush attachment, grinder and other “bells and whistles” are used to clean the damaged area. It is better to burn all removed waste.

If during the cleaning process it is discovered that the fungus has penetrated deep into the structure of the tree, this is a death sentence; the entire board or log must be replaced. In case of certain difficulties, the affected piece is cut out in a beam or log with a “small margin” and a new one is inserted.

Before the cleaning process, wet the surfaces, because moisture stops the airborne spread of fungal spores that arise during vigorous mechanical cleaning.

We fight with folk remedies

There is an opinion from a number of conservative experts that the use of chemical reagents in a bathhouse is inadmissible. What do they recommend for removing fungus with your own hands? Here are simple ways:

Bleaching powder. A solution consisting of quicklime bleach and water is applied to a previously cleaned and dry surface. In some cases, formalin is also added. I don’t know how the wood will feel after this “napalm.” But it helps against fungus.

Copper sulfate. The correct name is copper sulfate. It can be purchased at gardening stores. Here is one of the “cocktails”: per liter of water, 50 g. vitriol + 100 gr. potassium alum (medicinal drug) + 30 g. table salt.

Bleaching powder

Copper sulfate

Sulfur checker

Application to affected surfaces - with a roller, brush or spray. Be sure to use safety glasses and a respirator, or better yet, an insulating gas mask and OZK (just kidding).

Sulfur. Well, that’s basically an “atomic strike.” All ventilation ducts, door windows and large cracks are closed. A sulfur smoke bomb is ignited in a fireproof vessel (ceramic or metal). Approximate norm: per 100 m³ ≈ 200 g. The method is unsafe. During the smoldering process, sulfur gas is formed, which destroys fungal mold cells.

Accordingly, people should not be in the room. In terms of time, not quickly - 6-8 hours. Then a box of quicklime is brought into the room, which will absorb sulfur dioxide in a few hours and dry the air. But still, the peculiar smell will remind you of itself for many more days.

Hydrogen peroxide. The damaged wood surface is treated with a 20 - 25% hydrogen peroxide solution. The applied composition remains on the wood and acts for several hours before drying. Then the treated surfaces are wiped with a damp cloth.

Whiteness (or Domestos). If the mold is fresh, then, according to people’s reviews, “Beliza”, sold in hardware stores, is quite effective. After applying it, after about an hour you need to rinse the surfaces thoroughly with clean water.

In Rus', huts infected with fungus were often simply burned so as not to infect neighboring buildings. Not cheap, but cheerful...

By the way, iron sauna stoves are good because they warm up quickly. 2-3 hours of fire, and come in to steam, even in winter. But the fact that they cool down in 1-2 hours, without having time to dry the room, plays in favor of the fungus...