Linden or aspen for a bathhouse - which is better?

One of the most heated debates surrounding the Russian bath is the choice of the best type of wood as the main building material.

Most of these discussions, one way or another, are related to two species - linden and aspen. Although other materials can be used for construction - alder, cedar, larch, etc. Moreover, this question arises twice: the first time - when determining the material for the log house, and the second time - when choosing the lining for finishing the heart of the bathhouse - the steam room. To answer the question: linden or aspen for a bath - which is better, it is necessary to consider the advantages and disadvantages of each type of wood.

Which wood is better to build a bathhouse from: pine, linden, spruce, oak, aspen, pros and cons

The construction of a Russian bathhouse is traditionally carried out from wood of various species. But not all types of wood are suitable for building a bathhouse, so it is important to understand and understand which ones are better to choose. What kind of wood is best to build a bathhouse from, which one is suitable for finishing, we will find out why with our readers.

The wood for building a bathhouse is different. Each has its pros and cons.

Material for log house

A sufficient number of experts and connoisseurs of the classic Russian bath consider linden to be the most traditional material and the best in its characteristics.

Advantages:

- Quite light and soft wood, easy to process, and, as a result, construction from this material is less labor-intensive;

- Fast heating due to the low thermal conductivity characteristic of this type of wood;

- No shrinkage when drying the logs properly, which allows you to begin operating the bathhouse almost immediately after construction is completed;

- It is possible to use a steam room without additional clapboard covering;

- The presence of essential oils and resins that are extremely beneficial for health, giving a special microclimate to all rooms of the log house. Linden wood (especially in combination with linden honey) has a beneficial effect on colds, nervous disorders, and is useful for almost all internal human organs.

Flaws:

- Low resistance to decay, which even with additional processing leads to the relatively rapid appearance of fungi and, possibly, harmful insects. Together with the insufficient density of wood fibers, this entails a reduction in the service life of linden log houses;

- Relatively expensive material. Linden is noticeably more expensive than spruce and pine wood and, its main competitor, aspen.

Aspen

Advantages:

- Ease of processing and low weight of material;

- No drying out or cracking;

- Greater resistance to moisture and the appearance of fungus and microorganisms;

- The presence of oils and resins released when heated;

- It is possible to use a steam room without additional clapboard covering;

- Ubiquitous distribution, which, together with the previous properties, makes the material the cheapest possible option. Only pine is relatively competitive in price with aspen.

Flaws:

- Most of the advantages of aspen coincide with the advantages of linden, the problem is that they are all less pronounced than those of the latter. In other words, aspen is almost like linden, but the main word here is “almost.”

Disadvantages of a log bathhouse made of linden

When planning a bathhouse made of wood such as linden, you must take into account that it has its drawbacks. Disadvantages are inherent in almost any building material. Firstly, the linden must be thoroughly dried before use. If you don’t do this and lay out the walls from damp linden, it will darken very quickly. And if it often rains in a given region, then it is better to place a log bathhouse made of linden on a high foundation. In this case, the wood will not draw moisture either from the soil or from wet grass.

The second disadvantage is that the pleasant aroma of wood disappears very quickly. But it is he who is able to create comfort and a pleasant atmosphere during bath procedures. But still, the aroma of honey flowers can be preserved for a longer period. To do this, in the first years of operation of the bathhouse, you just need to splash water on the walls.

The service life of a bathhouse does not depend solely on what wood is chosen for its construction. Treatment plays a big role, so if the bathhouse is built from linden, there is no way to do without impregnation. It is also necessary to pay attention to the fact that this option is not very suitable for economical consumers. Especially when it comes to high-quality linden. Since a bathhouse made of such wood requires careful and more frequent maintenance, it is better to build it not on a summer cottage, but near a residential building.

Material for finishing a steam room

In addition to the already listed properties of each type of wood, the following should be noted in relation to use in the steam room.

Advantages:

- Linden has a very useful property specifically for steam rooms - even with strong heating, it is almost impossible to burn yourself with a coating made from it. This is especially true for lovers of high temperatures;

- The most pleasant smell of all wood types.

Flaws:

- Requires constant drying and regular maintenance. What makes the situation easier is that it is possible to replace damaged lining boards, which is more difficult to do for log logs;

- A change in the color of the material that gradually occurs with constant use. It becomes noticeable already 4-5 years after finishing the bath;

- Insufficient strength, quite naturally associated with the softness of linden wood.

Aspen

Advantages:

- When used in a steam room, that is, under the influence of high temperatures, the beneficial effect of the resins and oils released by the base wood is most clearly manifested. They are especially useful for respiratory diseases, as they have anti-inflammatory properties;

- Does not darken and practically does not change color even with prolonged use.

Flaws:

- slightly bitter odor, especially noticeable when heated.

Subtleties of choosing lining for a sauna house: linden or aspen

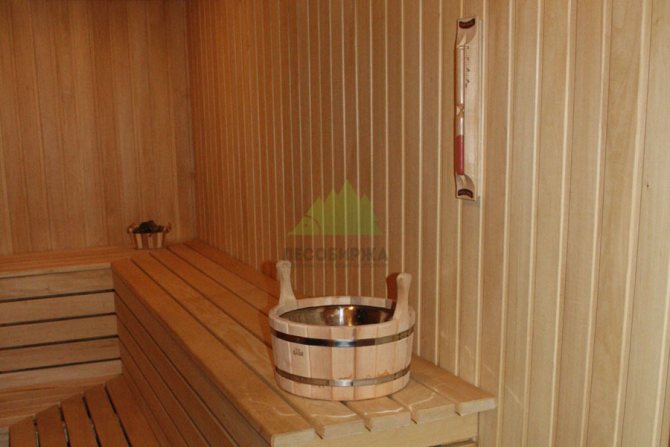

The interior decoration of a bathhouse using wooden lining becomes a classic example of preparing a room for use. If the owners of a log bathhouse made of logs most often prefer not to cover the spectacular walls, then a timber bathhouse with such finishing becomes more attractive and convenient to use. The popularity of this option is explained by the following qualities:

- The surface obtained using this material is flat and smooth, so there is no need for additional work.

- Wood and lining made from it are an environmentally friendly and safe material, the use of which in a bathhouse is acceptable and justified.

- Warmth in a room decorated with clapboard remains longer than in a room without additional finishing.

- Sound insulation is an important factor for owners of small plots who want to create the most private conditions for themselves and loved ones.

ADVICE! Decorating a bath house with clapboard will make it more lived-in and attractive. This technique should be used for buildings made of timber: for example, for the project “ Lumber bathhouse 4 by 5 meters ”.

What should be the ideal lining: linden or aspen

Is it more suitable for the difficult conditions of a sauna house? Structured information about both types of wood and their characteristics will help you make your final choice.

Linden lining for a bath

How to choose lining for a bathhouse: aspen or linden

is considered a priority option for finishing interior bath rooms. Most builders highlight linden lining as a more optimal option for a bathhouse due to its positive characteristics. The unique linden aroma that will delight visitors to the bathhouse is an undoubted advantage of this material. Although other characteristics of linden are also significant:

- this material does not heat up, which is important for those who like high temperatures, and does not emit resin;

- the dense structure of the wood virtually eliminates the possibility of cracks and damage;

- ease of working with the material makes it easy to update or replace worn-out finishing elements;

- linden has healing properties, positively affecting the nervous system.

IMPORTANT! Equally important for the quality construction of a sauna house is the installation of a reliable floor. You can read more about this in the article “ Floor in a bathhouse - which is better? ", posted on our website.

Which wood is better to build a bathhouse from - the pros and cons of different species

Our grandfathers noted in advance the trees for their bathhouse. They were cut in winter, when the wood has the lowest percentage of moisture. Such a log house practically does not shrink, and cracking of the walls will be minimal. But even carefully selected trees must meet a number of characteristics:

- Have increased resistance to moisture.

- Durability.

- Do not carry negative energy.

Let's figure out what features different types have, pros, cons of log houses in the form of a table:

- Low price.

- Not afraid of rot and mold.

- High moisture resistance.

- Availability in any quantity.

- Easy to chop or saw.

- At high temperatures it begins to cry.

- Without additional treatment it rots.

- It is not afraid of moisture and only becomes denser over the years.

- Slight shrinkage.

- Beautiful appearance.

- Durable.

- Minimal shrinkage.

- Doesn't crack much when dried out.

- In Russian regions, diseased trees with rotten centers mainly grow. Raw materials are supplied from abroad.

- High price.

- It is believed that aspen carries negative energy and in the bath it causes headaches and poor health.

- Difficult to saw and process due to high density.

- Low price.

- Availability in any quantity.

- Easy to process as it has a soft texture.

- Afraid of rot and mold.

- Excess moisture quickly destroys it.

- Susceptible to bug damage.

- Large shrinkage when drying.

- It will get dark in a year and the bathhouse will have an unattractive appearance.

- It is not afraid of moisture and becomes stronger than iron over the years. Venice stands on larch pillars.

- Tolerates any temperature changes well.

- Slight shrinkage.

- High heat-saving properties.

- Not afraid of bugs or mold.

- The price is 2.5 times higher than pine.

- Not afraid of high temperatures.

- Has a beautiful texture.

- High heat-saving properties.

- Price.

- Afraid of moisture.

- Lumber is made to order.

- Difficult to process due to the hardness of the wood.

- Does not heat up at high temperatures.

- Affordable.

- Easy to process.

- Darkens without additional processing.

- Short-lived.

- Afraid of moisture.

- Not suitable for log construction.

- Tolerates high temperatures well.

- Not afraid of moisture.

- Has high heat-saving properties.

- High price.

You can assemble a sauna frame from any wood. But for economy, pine wood is more often used. Pine and spruce are available in any region of Russia, but the high resin content does not make it possible to use them for interior decoration of a bathhouse. When heated, the walls and ceiling will begin to release resin, which can cause discomfort during procedures.

A bathhouse made of aspen will last a long time, and any fastidious owner will like its attractive appearance.

Expensive aspen, cedar and larch are optimal for building a log bathhouse. They tolerate moisture well and do not lose their quality characteristics over time. Saunas made of cedar and larch emit antiseptic vapors, and inside the steam room there will be a subtle and healing aroma. But it is not suitable for everyone, so we recommend that before construction you check whether the smell of wood will irritate family members. The price of the material is high and does not allow it to be used for construction.

Larch and aspen are mainly used as the lower crown of a log house. Over the years, the wood becomes stronger, and the bathhouse will last longer.

Linden and birch are available for construction, but we do not recommend building a log house from them. The steam room will not last long and will require repairs within a year.

Aspen lining: material features

A worthy alternative to linden lining is aspen lining, which has a whole range of attractive qualities. Builders who are thinking about which lining is better: linden or aspen, pay attention to the complex of qualities and the ratio of price and reliability of the material. In this confrontation, it is aspen that wins, since it will cost the customer less than linden.

ADVICE!

Aspen lining for a small bathhouse on the site is an ideal option for high-quality and reliable finishing.

This durable and resistant to negative influences material does not need to be replaced for more than 5 years. Among the obvious advantages of aspen lining:

- The strength of the wood structure guarantees a long service life of the material. Properly processed and protected from rotting, aspen is considered the most durable material for a bathhouse.

- Excellent thermal insulation properties that help maintain a comfortable temperature in the bath for a long period of time.

- Safety for humans, as well as tangible benefits of phytoncides secreted by the tree for the immune system and nervous system.

The choice of interior decoration for a bathhouse should be based on verified data on the material, as well as recommendations from specialists who have experience working with different material options. You should focus not on the cheapness or visual appeal of the lining, but on its physical characteristics and the quality of the material.

Which is better: linden or aspen lining?

And here he is faced with the need to place a bet on one of the two most frequently offered materials with similar properties. You have to choose: lining for a bathhouse - aspen or linden? Is it possible to say which type of wood is best for a bathhouse? Well, the difference between them is really not too big . Nevertheless, we will try to define it more clearly, compare the real characteristics of one and the other breed, and the final decision, of course, is for the reader.

Which lining is better for a bathhouse: aspen or linden?

Better is a relative concept. And here, as always, we advise you to identify your priorities. In the meantime, let’s take a more detailed look at what both types of wood are.

Advantages and disadvantages of linden lining for a bath

Let's start with the fact that “linden lining” tacitly implies that wood from one of the species of this genus . They are very similar in properties, so you should not check with the seller what type of linden. In general, things get to the point where they can sell you aspen under the guise of linden and vice versa - even out of ignorance.

The different species differ slightly from each other, but there is evidence that the hybrid of large-leaved and heart-shaped has denser wood, and therefore slightly harder and more durable.

The color of linden wood is very light - from white to yellowish, sometimes, however, the shade is slightly reddish or towards brown, but more often it is yellowish wood, without visible textures, without any difference in the color of the core and sapwood. The texture of the linden tree is practically indistinguishable to the eye; the annual rings are not visible. Looks smooth, like plastic.

But the most important thing for those who are looking at linden lining for a bathhouse is its characteristics.

The low density of linden wood and its loose structure make it a favorable environment and food for fungi. And despite the fact that the humidity in the bathhouse is high, and this is exactly the condition that mushrooms need, it turns out that you should use linden in the bathhouse only with confidence in ventilation.

Because antiseptic in the steam room and washing room, and these are the wettest areas of the bathhouse. So it turns out that you either need to be prepared for frequent repairs of the lining, or minimize the time the wood is exposed to water. As an option, you can coat the wood with impregnations, which will significantly reduce the amount of moisture absorbed. (For information on impregnation, see the article Finding out how to treat lining in a bathhouse.). You may also want to consider purchasing impregnated wood.

In all reference books, linden's resistance to fungi is considered the minimum level for wood . However, it is worth asking why this tree is so persistently recommended by craftsmen and participants in various forums.

Of course, this can be called a tradition. It was once noticed that doors made of linden do not jam in the opening after bath procedures. This is a sign of slight swelling of linden under the influence of humidity. Therefore, linden is actively used for the production of furniture and windows.

Photo: bath door (linden)

But here’s what’s interesting: we ourselves easily repeated this common statement until we decided to look in the reference books. And this is what was discovered:

Please note that aspen shows better characteristics than linden. But why doesn’t it have the same fame as the linden tree? We will offer our version a little lower, but for now we will assume that the glory of linden as the only wood with low swelling is slightly exaggerated .

Among both the advantages and disadvantages is the fact that linden has soft wood that can be easily processed. If someone decides to plan and polish it with their own hands, then this will be an advantage, but during operation it is rather a disadvantage, because it is easy to damage the linden surface.

At the same time, it chips a little worse than aspen, so in this matter the advantage of linden is clear.

Another circumstance that sometimes turns out to be decisive when choosing is the smell of linden wood. But it is subtle and unobtrusive.

We will remain silent about energy because we have absolutely no understanding of it. Who is the donor, who is the vampire, and whether this is important during bath procedures - decide for yourself.

Who likes to get information from videos - almost everything is said in the video below:

Linden or aspen lining - which is better for a bathhouse: the pros and cons of aspen

Aspen is a member of the poplar genus, so its wood can be sold together with black or white poplar wood. In Europe the markings will be different, in Russia... we can assume that there are more aspens than poplars, so the probability of buying aspen is quite high.

However, the strength characteristics of aspen and poplar are very similar, so if anything matters here, it is that aspen tolerates moisture and even being in water better than many others.

At the same time, its resistance to fungal attack is at the same level as that of linden, it is almost the same and very low.

If you carefully looked at the plate above, you noticed that according to its data, it turns out that aspen gives even less expansion and contraction when moistened and dried out than linden. So why isn’t aspen the favorite of bathhouse owners?

We think that the whole point is that it is not resistant to infection even during the growth process. Aspen reaches maturity at the age of 30-50 years, at this time it has the thickest trunk, but, unfortunately, many trees have a rotten core inside.

Therefore, a good aspen board is rare . The selection has to be carried out more carefully, despite the fact that a lot of aspen is harvested. But it is used in the same match industry, so, good or bad, it does not lie dormant outside of construction.

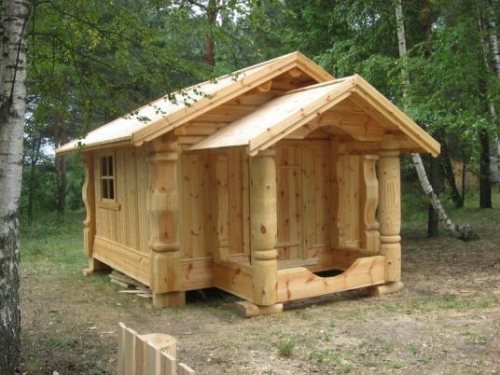

Log bathhouse made of linden

The history of the construction of bathhouses dates back more than a dozen centuries, and maybe much more; the bathhouse is loved by the people of Rus'. From time immemorial, a bathhouse has been built from wood, namely from logs, mostly linden, because this tree is best suited for a number of undeniable quality characteristics: the wood is soft, does not contain resins, low thermal conductivity, and it is also believed that a bathhouse made from linden has less carbon emissions. So let's look at how you can cut down a bathhouse yourself and what you will need for this.

Materials

Tools

- axe

- hacksaw

- chainsaw

- hammer

- shovel

- Master OK

- level

- container for solution

- roulette

- electric planer

- a circular saw

- screwdriver

The process of building a log house and a bathhouse as a whole, from start to finish.

Our ancestors gave a special place to the bathhouse, in some ways even sacred, because in the bathhouse the elements of fire and water converge for human health. It’s not for nothing that they say, “When I went to the bathhouse, I felt like I was born again.” In the steam room, the body and spirit are cleansed, all the negativity and all the ailments and illnesses come out, which is why we are a people with a broad soul.

And so the first thing is to decide on a place for construction, for example, the author chose next to an old bathhouse, not far from the house. According to the belief of the ancestors, it was strictly forbidden to build on the site where the bathhouse used to stand, on the site of the fire. You need to choose a new, unused location.

The beginning of it all was, of course, the marking of the site.

After the area has been marked, the author begins to prepare the formwork; it can be made from boards or thick plywood, fastening everything into a single structure as in the photo.

Then the solution is poured into the prepared formwork, the author ordered ready-made concrete, played it safe and bought it with a reserve, in short, the result was not a strip foundation, but a monolithic slab, which, by the way, is also not bad. While the cement is gaining strength and getting stronger, it is advisable to wet it periodically throughout the week, so it will become even stronger.

After a week, the foundation has dried out and the author slowly begins to prepare for the construction of the log house, the first step is to lay the waterproofing, the master uses simple roofing material laid in several layers. As soon as the insulation is ready, the first crown is laid, here the author used a square-section beam, it is advisable, of course, to use hard wood for the lower crown, for example (oak), this is what our grandfathers and great-grandfathers did because there was no drain in the bathhouse and all the water and moisture simply went away in the gap between the floorboards, thereby the lower crown was exposed to the aggressive influence of moisture.

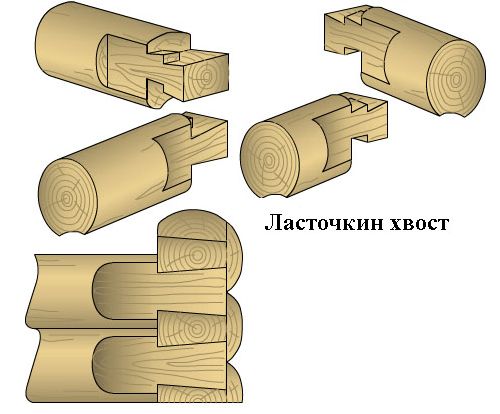

After the first crown is laid, work begins to boil. The author uses the “dovetail” method for laying the log house; according to him, it is the easiest for a novice carpenter. Here's a small diagram.

This is the way the walls of the log house are built, crown by crown.

In the work, the author uses his grandfather’s old ax “Family Heirloom”, passed from father to son, only the ax was changed when it became unusable or broke, but the ax is excellent, the steel is of the highest quality, not like today.

And now, crown after crown, the log house is slowly growing.

And now the height of the log house reached 2.5 meters.

Next, the author proceeds to constructing the frame of the dressing room and sawing through the entrance to the bathhouse.

The frame is installed from timber, the author gives advice to followers - when constructing the frame, you should choose the distance between the load-bearing pillars such that the width of the insulation is 1.5 cm greater than the distance between the pillars.

After the frame and frame are ready, the master proceeds to creating the rafter system, first everything is done on the ground.

Then work at height takes place.

Next, the sheathing is sewn on.

Next, an extension-entrance was made.

The rafter system was made and adjusted to the main one.

The roof turned out to be a little complicated and requires laying a metal sheet bent at an angle directly at the junction of the two roofs.

Dimensions of linden lining for a bath

Since readers are interested in the dimensions of linden lining for a bathhouse, we will try to satisfy their curiosity.

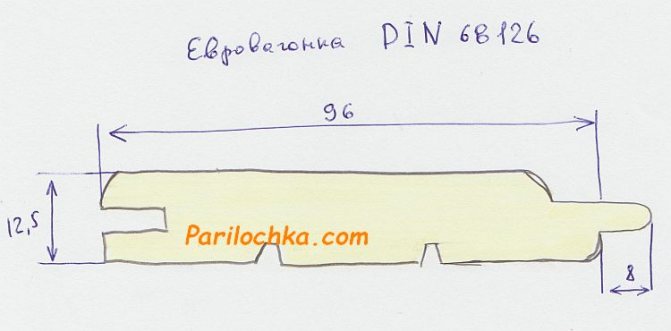

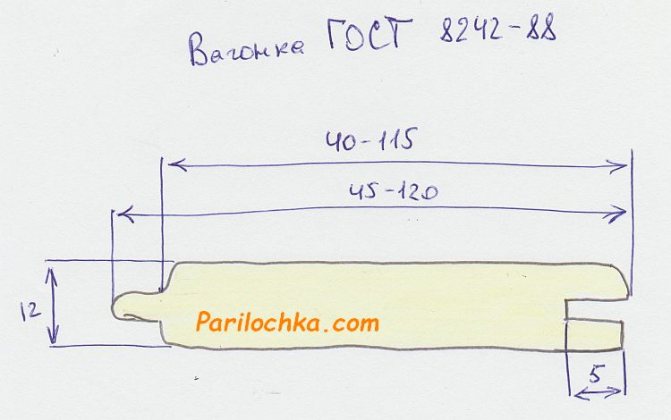

Let's start with the fact that asking the question as if there were a separate standard for linden lining is not entirely correct. Linden is a material, and the shape of the profile board is determined not by it, but by GOST or DIN - depending on which consumer it is produced for, because DIN is a Western standard. In Russia, DIN is used as a standard for the manufacture of Eurolining.

Unfortunately, the matter is not limited to two standards.

This is what Eurolining looks like according to DIN:

And here is the standard for the manufacture of Russian lining:

This is only one option; on sale the thickness can vary from 12 to 40 mm.

I would like to clarify for those who are planning to buy lining that it also happens that unscrupulous sellers name the width of the lining together with the tenon - this is a few millimeters more, then the tenon will disappear in the groove, and you will miss the required meters.

The shape of the lining can be with sharp or smooth chamfers, with an elongated tenon that creates a discharge between the lamellas, with or without relief. The lining imitates timber and rounded logs; the profile can be concave, convex, or straight. All these varieties can be successfully made from linden.

Therefore, in a situation where you want to calculate the required amount of lining before purchasing, you should contact the nearest sellers, see what they have, and then make a calculation from what they have. This is the most rational thing, because any manufacturer may have its own variations of the form and additions to GOST.

In the bath: linden or aspen?

Tell me, good masters, resolve my doubt: What is better in the steam room? Linden or aspen? It is known that aspen turns black over time. Does linden turn black?

Abash is best, it doesn’t get so hot. In this case, I would prefer linden. If it gets dirty over time, it can be easily sanded and cleaned up. It's more difficult with aspen.

Aspen is intended for use. And the abash on the shelves, although if you have an aspen board, then it’s better, there’s no difference in thermal conductivity.

Aspen darkens faster, linden rots faster, although in a properly made and properly operated steam room, linden will also last quite a long time.

How is it fast? The aspen in my steam room is 7 years old and it hasn’t darkened at all.

Aspen or linden doesn't matter. Both are good. The main thing is to immediately saturate the lining with a special composition for baths, without waiting for it to darken (and any unprotected wood will darken). It's called Soupi (I may have made a slight inaccuracy). Made by Sadolin, sold with us without any problems. Renew once every five years and no darkening. Special oil is sold for shelves, which is absorbed into the shelves and prevents them from absorbing dirt through sweat. If you don't mind the money, then it's better to put abashi on the shelves so that the butt doesn't burn. 3-4 pieces are laid on top of ordinary boards with a gap of 3-5 cm.

As far as I remember, my father made it from aspen and impregnated it with a special compound. We have been actively using the bathhouse for the 4th year now.

everything is white and beautiful, but as for the shelves, we’re just warming the sheets and it’s not hot

The shelves are linden and the walls are aspen. If the bathhouse is Russian, then both the pine and the other will turn black. Aspen does not rot like that. Soft linden on the shelves and the pleasant smell of honey.

aspen vampire linden donor

) why would it rot in the steam room? I steamed, ventilated, dried - all the mold will be killed by the heat and steam, the walls will quickly darken from the soot flying out of the vent. For example, I like black walls and it’s healthier - coal cleans everything. I don’t recommend using anything to paint with

Aspen for vampires, linden for vampires

. There is no need to cover it with anything. Walls and floors can be made of pine. But in general there is cedar on the floor, aspen on the walls in the sink, pine in the steam room, linden on the shelves, pine and aspen on the walls.

If we are talking about impregnations, then it doesn’t matter what you put in. It’s just that in normal baths, especially in steam rooms, it is undesirable to use such things. I know, I know, now a huge discussion will begin with examples from different manufacturers with special impregnations. All these impregnations do not add either health or pleasure. Only beauty. Here everyone chooses for themselves. The best option is to go over the walls and shelves with fine sandpaper once every two years, and again, a fresh bathhouse in which there is light steam. And to prevent it from getting dark and moldy, after use it is advisable to keep the heat on for at least two hours for complete drying.

“Walls and floors can be made from pine. "

Complete nonsense! Who uses resinous rocks in a bathhouse, especially on the floor? Resin is actively released from high temperatures. From time immemorial - only deciduous ones!

Finishing the bathhouse with clapboard

The interior finishing of baths and saunas is usually done with lining. In baths and saunas, several types of lining are used: cedar lining, linden lining, aspen lining, abashi lining, alder lining. To choose the best lining option, or a combination of several types of wood, let's look at the advantages and disadvantages of each type of lining.

Aspen lining is a fairly common option for finishing walls and floors in a steam room. Aspen is practically very little susceptible to rotting, is very moisture resistant, fungus does not spread in it, has low thermal conductivity, is very durable, does not bend when heated and does not crack. A very big drawback of aspen is that it darkens over time, so after some time of use your steam room may turn into different unexpected shades.

Features of linden for building a bathhouse

What is the most basic difference between linden and any coniferous wood? If anyone is not involved in carpentry work or is not familiar with carpentry, then he does not know that pine, spruce and other coniferous wood dries out over time. And this means that not only cracks appear in it, but it can be deformed and pulled to the side. But linden, even at a fairly high temperature, is not able to dry out. Why is this so important?

The big problem in any log house is the cracks that appear between the logs over time. And then the cracks that appear have to be caulked. This occurs due to shrinkage of the log house. And since linden does not dry out, you don’t have to worry about any cracks. They will not appear even over time, when the wood “gets old” and darkens. And this also shows why a linden log house for a bathhouse is in great demand among connoisseurs.

Good to know! Having built a log bathhouse from linden, you can enjoy bathing procedures immediately when the roofing and interior work is completed.

How long will it take to build such a bathhouse? Experience shows that 3-4 weeks will be enough for this. It is necessary to pay attention to another very important point: the cost of building a linden bathhouse. Such a building will cost much less than if it is made of pine. But this building material is considered one of the cheapest. What is the reason that a linden log house for a bathhouse with your own hands is not very expensive?

Everything is very simple here: if we are talking about logs made of pine needles, under the influence of temperature such wood releases resin and aroma, which not everyone may like. In order to get rid of this, the walls and ceiling are finished with clapboard made of the same linden, aspen or other hardwood. This means that additional money will need to be allocated for such finishing. And if the log house of the bathhouse is built from linden, then interior decoration is completely unnecessary.

Good to know! If a log house is built from linden timber, it will be more durable than if it is built from other wood only under one condition: the correct selection and use of an antiseptic.

One more very important point must be taken into account: linden wood is quite easy to process. And this applies not only to its division into parts. After all, when building walls, you can immediately cut decorative ornaments into logs. And although linden retains heat well, you need to choose the right section of logs. A lot here depends on the climate in a given region, very cold or not.

Lining for a bathhouse, what to choose? Aspen, linden or cedar

What material can be used for a steam room so that the high temperature does not affect the quality and appearance of the board?

Having worked in the field of construction and wood finishing for a long time, we know how this or that type of wood behaves in operation, what material will be environmentally friendly and most durable. So, finishing the bathhouse with clapboard, which option from the ones presented below is suitable for the interior lining of a room with a high temperature?

An important condition for lining a bathhouse with clapboard is the absence of resins

, the ability of the material to withstand both sudden temperature changes and high humidity.

And of course, the natural beauty of the panels is very important here - texture and high performance characteristics. Photo 1. Steam room made of linden Photo 2. Arrangement of the shelf

Very beautiful in its texture, contains few resins

, due to which it practically does not heat up.

The disadvantage of this material is that aspen quickly loses its natural beauty

and begins to look dirty-gray, its service life is not short, but, unfortunately, its appearance, after a couple of years, will force you to cover the room with another lining for the steam room.

Lining a bathhouse with linden eurolining is a pleasant and rewarding job. From time immemorial, the properties of this wonderful material have been known - low thermal conductivity (due to the absence of resins), light, healing aroma (lasts for the first six months), beautiful white linden color. Choosing such lining for your bathhouse is an excellent option.

By the way, a very common question is which is lighter in weight: linden or cedar?

Linden lining weighs less than cedar, but not by much. If a cube of linden weighs 400 kg, then a cube of cedar weighs 420 kg.

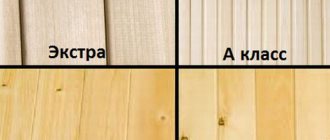

Photo 6. Linden sauna, “Extra” grade

Photo 7. Linden eurolining in the steam room Photo 8. Linden eurolining

From the minuses

One can emphasize

cost

of the high grade “EXTRA” (in grades “A” and “B” - this tree does not look beautiful due to frequent black knots) and the fact that it is almost impossible to find a calm profile in the market, and eurolining has gone out of fashion, although and has higher performance properties.

Cedar lining for a steam room is perhaps the most attractive option for every zealous owner. Who hasn’t heard about the wonderful properties of this Siberian giant? Its wonderful aroma (when finishing with steam paneling, the smell will be revealed with each kindling), its healing phytoncides, which, entering the air from the heat of the stove, will penetrate every cell of the body, providing a medical effect, increasing your immunity and mood.

Yes, the cedar bathhouse is an invention of the strong, healthy inhabitants of Siberia; for the inhabitant of the metropolis it will be a source of health and longevity.

Photo 9. Steam room lined with cedar lining, grade AB

Photo 10. Cedar lining on the ceiling of the sauna Photo 11. Grill for the sauna

From the minuses

There is only one thing to note about cedar lining for a sauna

- the knotty nature of the boards

. Unfortunately, nature decreed that the fragrant resin of cedar is located precisely in the knot area and high-grade panels have practically no odor, although they retain other properties: they do not heat up, do not grind, such lining lasts a long time in the bathhouse, acquiring over time reddish shades and an interesting contrast between hard and soft layers of wood.

Deciduous wood for the construction of a bathhouse

Deciduous tree species are no less in demand for assembling a log house for a private bath. They can be used not only for the construction of structures, but also for interior decoration.

To build a strong and durable bathhouse, experts recommend choosing oak - one of the most wear-resistant and hard types of wood, which is designed for use in conditions of high humidity.

The disadvantages of the material include high cost, complexity of technical processing, significant weight and the need to build a reinforced base. Therefore, a steam room made of oak is built less often than from other species.

Soft wood, which is characterized by its low cost, ease of processing, attractive appearance and low thermal conductivity. Therefore, an aspen bathhouse does not require frequent repairs. This is explained by the material’s resistance to rotting and deformation during prolonged exposure to high humidity. Do not forget that aspen is not capable of releasing resins when heated.

Another representative of deciduous species is linden. This material is quite in demand for the construction of baths. It is light and easy to process, resistant to deformation and shrinkage. In addition, linden has low thermal conductivity. This ensures quick heating of the linden bath and preservation of thermal energy for a long time.

Among the disadvantages of the material are high cost, short service life, loose structure, susceptibility to rot and mold. For this reason, the linden bathhouse requires careful ventilation and drying.

White, black and Siberian alder are used to build bathhouses. In terms of performance characteristics, it is similar to pine - it is resistant to shrinkage, deformation and rotting.