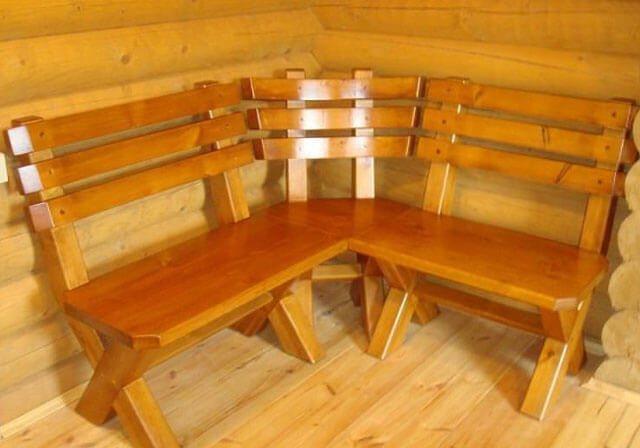

Since there is no high air humidity in the rest room, benches do not have to be made of hard wood. Furniture for the rest room can be made from any wood, but the material must be carefully processed before use.

Portable wooden benches with backrests are usually installed in the rest room. It is worth remembering that benches in the rest room should be more comfortable.

How many benches should there be in a bathhouse?

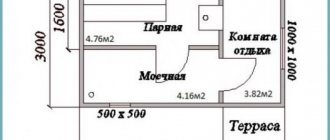

To calculate the optimal number of benches for a bathhouse, it is necessary to draw up a drawing of each room and place the benches in them in such a way that they do not interfere with free movement and at the same time allow the number of people for which the room is designed to be accommodated.

Benches for sitting should be placed in the washing room, based on the number of people who will use the bathhouse at the same time. Usually in small buildings there are 2 shops, one of which is intended for two, and the second is created for one person.

In the rest room, benches are usually installed near the table and are large in size, since they are intended not only for sitting, but also for lying.

Making a bench for a bath

Wood selection

Oak is one of those materials that is not afraid of moisture

The bathhouse itself can be built from various materials, but the furniture is made only from wood.

And not just anyone, but one that meets certain requirements:

- A bench for the bath: do it yourself, it should be made from moisture-resistant wood with low thermal conductivity. Not every material can withstand high temperatures and humidity.

- Wooden benches must have an enviable resistance to cracking. In particular, an excellent bench for a bathhouse - made with your own hands, from oak, birch, linden, maple, aspen and poplar. Deciduous wood does not emit harmful resins, does not burn the skin, is easy to clean and dries quickly.

- All of the listed types of wood have ease of processing, a minimum number of knots and good density, that is, important advantages. Well, they have an excellent property that is inherent in all of the listed breeds, this is the content of useful substances that have a healing effect on the human body.

Bench manufacturing technology

The simplest design for saunas consists of legs and boards that are secured as a seat. It is created as follows:

- First, a drawing of a sauna bench is created, which indicates the dimensions of each structural element.

- After this, the legs are made. For this, bars with a cross section of 50x50 mm are usually taken.

- Then grooves are created on the inside of the supports. This is necessary to install the transverse bars connecting the legs. The connection does not only occur at the top of the supports. At a height of 1/3, additional bars are installed that connect the legs. Subsequently, they are connected using a bar in the middle, located along the structure.

- After securing the lower longitudinal support, the transverse bars are connected using boards. For greater stability, grooves are created in them.

It is necessary to leave gaps between the boards so that water does not accumulate at the joints. The screws should be tightened so that the head is completely recessed into the wood. The holes must be filled with a mixture of PVA and sawdust. After manufacturing, the bench needs to be plastered. To make the bench safer, it is worth removing sharp corners using sanding discs.

Care Tips

Sauna benches are used in difficult conditions and therefore require special care. To make wooden furniture last longer, you need to follow these recommendations:

- regularly ventilate the room to avoid the development of fungus and mold;

- Complete each bath day by cleaning all rooms and drying all equipment;

- periodically you need to heat the bathhouse empty, bringing the temperature to 100 degrees (to destroy all pathogenic microorganisms);

- From time to time inspect the structures for the appearance of rot.

A wooden bench is a mandatory attribute for a bathhouse, which requires proper care. You can make it yourself, and it won’t take much time.

Do-it-yourself bathhouse benches are regularly influenced by many negative factors. Proper care will help extend the life of products:

- systematic ventilation of the bathhouse will prevent the spread of mold and mildew;

- after each visit to the steam room, it is necessary to thoroughly clean and dry each item;

- If stains or dirt appear on the bench, you can remove them with a warm soapy solution; it is better to avoid chemical and aggressive detergents;

- from time to time the bathhouse is heated idle; it is enough to bring the temperature to 100 degrees to destroy all pathogenic bacteria;

- periodically the surface of wooden structures is treated with antiseptic agents;

- benches are regularly inspected for damage, rot, affected elements are removed and replaced with new ones.

If you are making a bathhouse bench with your own hands for the first time, you should follow the recommendations of experts. Each element is polished until the surface condition is ideal. The corners of the product are rounded to reduce the risk of injury. It is better to use wooden fasteners rather than metal ones.

Making a sauna bench with your own hands is not a difficult job, the main thing is to use high-quality materials and follow the technological features of the process. The simplest shop will turn out original thanks to its unusual decor. The designs look interesting, complemented by lighting, which helps create a light, relaxed atmosphere.

Systematically ventilate the bathhouse

Bench finishing

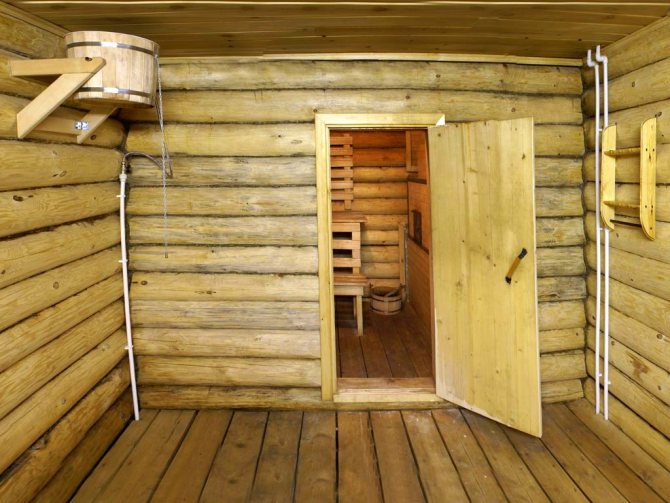

In order for the created benches to be combined with the style of the building, it is necessary to select certain materials and choose the type of construction in advance. For a traditional Russian bath, for example, you can make massive benches from logs. They will be combined with the overall design and will complement the interior. To make them look more harmonious, you can use water containers made of wood.

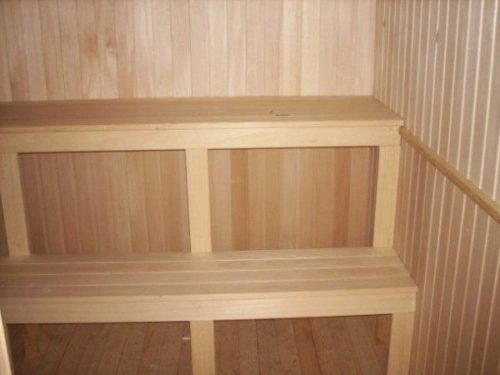

Sauna benches are distinguished by their strict shapes and polished surface of the boards. They are usually made from light wood. It is worth remembering that for saunas, it is usually not portable benches, but structures that are fixed near the wall. The side surfaces of the sauna product are finished with boards, so they resemble the canopy installed in a Russian bathhouse.

If you want to create a bathhouse in a colonial style, you should make benches from roughly processed boards, on which the structure of the material can be seen. If a bench with a back is created, it is made with massive armrests.

Country-style bathhouse benches are made from boards that are not perfectly level. But you should also choose materials with the expectation that the bench will be comfortable, despite the bends of the material.

Creating a bench for a bath or sauna can be a complex process only if you want to decorate it in an unconventional style, since this requires spending more time on drawing up drawings and finding suitable materials. In other cases, making a bench for a bathhouse is quite simple.

Material selection

It would seem that nothing could be easier than choosing the material for the future structure. Some people think that even coniferous varieties are quite suitable for making benches. Actually this is not true. When heated, resin will appear on the surface of the furniture, which can cause a burn. Such wood options are suitable exclusively for a washing room or recreation room, but not for a steam room.

Aspen also seems like a good option. However, during operation in humid conditions, such a bench will begin to rot from the inside. Oak is really suitable for making structures, although high-quality material costs a lot. Let's consider the classic varieties of trees for furniture in a steam room.

High density (500 kg/cm3) allows the material to withstand the effects of elevated temperatures, such furniture does not overheat. During the heating process, this wood releases useful elements into the air. Linden is easy to process; it is pliable. However, it also has disadvantages. You cannot do without pre-processing the wood before making the bench. If you neglect preparation, the material will accumulate moisture and begin to deform, and then completely rot.

From a price point of view, pine is considered the most profitable material. Select good quality specimens. The wood should be free of various knots, blue stains and resinous pockets. Unfortunately, all the main advantages of the material end at an affordable price. Pine has a low density, so this product will not last long. Changes in temperature and humidity levels will lead to deformation and cracking.

Birch

This is heavy wood with high density (600 kg/cm3), which allows the bench not to react to changes in humidity. The thermal conductivity of birch is at an average level, but there will be no burns when heating the bench. The material has good viscosity and does not deform during operation. It is easy to process: it is malleable. For a steam room with birch benches, it is important to ensure good ventilation.

Meranti

Red wood has a high density (610 kg/cm3). This material is dense and heavy, so you will never encounter overheating of the bench. This design will be resistant to temperature changes and humidity levels. This tree has no knots and is characterized by low fiber, making it easy and pleasant to work with.

This is truly an ideal option for making a bench for a bathhouse. The porous structure of the material has no moisture and no tendency to accumulate. The density of the material is quite small (only 390 kg/cm3), but it does not heat up even with significant heat in the steam room. It is not difficult to guess that such wood is expensive. This is mainly due to the delivery of raw materials from Africa.

The bench for the bathhouse is made with your own hands only from a certain wood. Pine, for example, is not suitable because it contains a lot of resin, and when heated it releases. Also, for example, an iron hornbeam is not suitable. This wood is very resistant to water and moisture, but unfortunately it gets very hot and literally burns the skin.

We invite you to familiarize yourself with the Finnish sauna and its health benefits.

The best choice for a bath bench are the following types of wood:

- linden - heats up weakly even in a sauna, tolerates steam well, emits a wonderful aroma, the only drawback is that linden wood darkens over time;

- aspen - superior to linden in resistance to steam and water, but has the most ordinary smell, is also inferior in attractiveness to linden, but is not at all prone to mold if you managed to purchase clean wood;

- larch - under the influence of water and steam it only becomes harder, benches made of larch last for several decades and do not change color or texture, the disadvantage of the material is its high cost;

- cedar is an exception from coniferous species; when heated, the resin is released slightly, but phytoncides evaporate; this material is recommended for use in finishing steam rooms for bronchitis, asthma, and lung diseases;

- oak - more suitable for a do-it-yourself bench in the dressing room, it tolerates the action of water and steam well, is exceptionally beautiful and durable, however, due to its high density, such wood heats up more in the bathhouse, and its cost is very high;

- birch - the material for the Russian bath is traditional and respected in former times, but now it is rarely used; birch is not as resistant to moisture as aspen, for example, it is less resistant to rotting, and when heated it releases tar, the finish and benches in the steam room turn black quite quickly; The release of tar is what makes birch trim so valuable: tar has amazing healing properties and relieves many skin diseases, including contagious ones.

The lining material of the steam room and the bench may not match. This is not a mandatory requirement, but recommended, since the contrast between the bench and the wall, heated to different degrees, is unpleasant.

Making bath furniture with your own hands

Choosing wood

In a bathhouse, like in any other room in which a person spends time, there should be furniture. At the same time, it must be taken into account that the special conditions in the bathhouse and sauna (usually high humidity) impose their own requirements and impose restrictions on the choice of material.

Wooden bath furniture

If we talk about furniture for a steam room, it should be able to withstand high temperatures and humidity, have low thermal conductivity, be safe and not emit toxic or potentially hazardous substances when heated. Despite the presence of a large number of different types of materials, only wood meets these requirements, and even then not every one.

Two-tier bath bench

To carry out a more complex design, a drawing is needed that allows you to take into account all the nuances and details during installation. And working with the circuit is much easier and faster.

Let's consider a design for a steam room with the following dimensions:

- width – 3 m;

- length – 3.6 m;

- height – 2.4 m.

- When installing the bench near the longest wall, we mount a frame made of 50x70 mm timber.

- For the top shelf you will need 12 beams of 110 cm each, and 6 pieces of 90 cm each. To assemble the lower shelf you need to prepare 6 beams with a length of 140 cm, and 6 pieces of 60 cm each.

- Seats or floorings are made of boards 20x120 mm, the length is equal to the length of the wall. To assemble the upper tier, you need to prepare 7 boards, for the lower - 4. When fastening the boards, you should leave a gap of 1 cm between them (for ventilation and water drainage).

- You should also prepare 3 beams (or boards) to make a horizontal tie between the six posts of the upper and lower shelves.

- When making the upper tier, we knock down the racks with the letter “P” and connect them with two boards. We attach the structure to the wall using 5x5 cm or 10x10 cm blocks (for ventilation).

- The racks of the lower bench are knocked together using the letter “G”, which are connected with the long side to the two racks of the upper shelf. This fastening balances the lower tier and gives stability to the upper tier. The lower racks, as well as the upper ones, are connected by boards.

- The frame is ready. Now you need to lay the boards of the lower and upper tiers on it. To complete this job, you will need fasteners to make the connection from the inside of the support, such as wooden nails or pins.

The two-tier bench for the steam room is ready.

Types of benches for baths

Among the models of bath benches, there are portable and stationary options.

Their sizes directly depend on the area of a particular room. In most cases, the parameters of the benches are 60-70 cm in length. When making multi-tiered structures, the distance from the ceiling surface to the top point of the bench should be within 1.2-1.3 m. Often, portable-type structures are smaller in size compared to stationary varieties. Choose a bench for a wooden bath taking into account its purpose, the size of the room and the expected number of people. Benches are distinguished by type of construction:

- Single-tier, characterized by mobility and ease of use. This option is more suitable for small steam rooms. The benches do not take up much space and can be easily moved to the desired location. The bench can be taken out into the open air to dry without any problems or for carrying out repair work on them. There are flat and angular models; they are also good to use for the locker room. Even home craftsmen can make such a wooden bench; moreover, it does not cause much trouble in maintaining it.

- Two-tier, used in spacious baths. They are mounted along blank walls where there are no windows or ventilation holes. You should also pay attention that when installing the bench it is not very close to the stove, otherwise there is a high probability of burns. To access the second tier, a special ladder is used.

- Three-tier, installed mainly in steam rooms. On the highest bench, the visitor has the opportunity to be exposed to high temperatures. The middle tier is made stationary, and the rest are made mobile. The main thing is that the distance between all tiers is at least 1 m. The dimensions of the lower bench are up to 60 cm in width and up to 95 cm in length, the middle and upper tier can be made in larger sizes.

- Stepped, where the lower tier acts as a step. You can stand on it and use it as a seat. So that an adult can lie down on the bench, the tier is made in larger dimensions.

Thanks to the variety of wooden benches for a bath, choosing the most suitable option will not be difficult. It is important to use high-quality material and adhere to manufacturing technology.

Digging holes

Using a garden auger, I dig holes for the legs of the bench. A total of 6 holes were required - 3 in the center and 3 on the edges.

Note! You can also use a rented electric drill, but for homemade work it is more important to use available tools.

I determine the height of the bench and fill the legs with soil, having previously set the guides to the level.