The main function of the front door is to protect the home from unwanted visitors. One of these unexpected guests are drafts and cold entering the house from the street or from the entrance. History does not know for certain when exactly primitive man, protecting himself from the weather, covered the entrance to the cave with a skin, but the “evolution” of the skin into a modern door, equipped with ingenious locks, is obvious.

Our contemporaries can choose between various options for plastic, wooden and metal doors. But the question of how to insulate the front door with your own hands remains relevant to this day.

The front door is the calling card of your home

How to insulate a wooden entrance door - What material can be used

Often, before insulating a wooden entrance door in a private house, the question arises: “What material can be used to insulate the entrance opening?” And this is reasonable. After all, future comfort, for the sake of which this event is planned, depends, no less than much, on the chosen heat insulator.

It is worth noting that just a few decades ago, only felt, foam rubber and dermantin were available for insulation of external doors. Now, the choice is much more varied. In addition to old thermal insulators, manufacturers of thermal materials today offer the following products:

- Mineral wool;

- Izolon;

- Styrofoam;

- Expanded polystyrene.

Mineral wool and polystyrene foam

Mineral wool, like foam plastic, is often used as a basis for insulating metal door panels. Both heat insulators perfectly retain heat inside the building and are less susceptible to the influence of microorganisms. Mineral wool is also worth noting because most rodents prefer to “bypass” this heat insulator.

Mineral wool insulation

But the materials presented above have some restrictions on use. Polystyrene foam belongs to the category of super-flammable insulation materials. Therefore, this heat product can be used for working with wood only when treated with a special compound. And mineral wool has the “disease” of subsidence. Over time, the mineral wool lining may end up at the bottom of the door leaf and stop keeping heat at the proper level. In addition, mineral wool quickly accumulates moisture inside itself. Such a negative undoubtedly reduces the service life and significantly adds weight to the entire door structure. Therefore, the use of this heat insulator for insulating the doors of a bathhouse or sauna is not recommended.

Application of isolon

Correct use of isolon is more appropriate to achieve the goal of effectively retaining heat in the house. The heat insulator is made on the basis of foamed polyethylene. This base gives it minimal thermal conductivity. The advantages of this material include the fact that for thermal insulation of the door, a sheet with a thickness of 10 - 15 mm will be sufficient. Such parameters allow you to maintain not only the attractive appearance of the door leaf, but also do not allow you to thicken the structure and not make it bulky.

Isolon insulation

Use of expanded polystyrene

Expanded polystyrene also has good performance. A door insulated with such material will become a reliable and safe barrier between a warm house and a cold street. Among the obvious advantages of expanded polystyrene, one should also highlight its non-flammability. When an open fire occurs, the flame on the surface of this material will gradually die out.

For budget-friendly door insulation, you can always use foam rubber. This warm product is convenient in all respects, and for a novice specialist it will be a real find. Foam rubber will easily “forgive” all mistakes and allow them to be corrected quickly and painlessly.

Who is to blame?

Gaps between the opening and the door frame. In the case when the doorway is slightly larger in size than the frame, significant gaps are formed. In this case, the latter must be blown out with a continuous layer of polyurethane foam. Otherwise, it will hardly be possible to achieve heat savings in the room.

Slots and gaps between the door leaf and frame. This cause of heat leakage occurs due to the box being skewed due to improper installation or due to high humidity in the room. This reason is especially relevant if wood is chosen as the material for the door frame and the leaf itself. Also, the appearance of such gaps and cracks can be caused by deformation of the canvas or hanging fittings. In this case, you cannot do without replacing the door leaf itself or the door frame.

How to insulate a wooden entrance door – Tool for thermal insulation

It is well known that it is almost impossible to perform any work efficiently without the proper tools. For high-quality insulation of wooden entrance doors with your own hands (on your own), you will need the following tool:

- Tape measure and pencil;

- Stationery knife;

- Hammer;

- Screwdriver;

- A flat rod or metal meter;

- Hacksaw;

- Mounting tool or nail puller;

- Construction stapler.

If necessary, this set of tools can be slightly expanded. But for most thermal insulation operations, the presented set will be quite sufficient. It should also be noted that an ordinary hacksaw can easily be replaced by an electric jigsaw. Such a power tool allows you to get the job done much faster, without compromising quality at all. And if there is no screwdriver in the house, then you can use a regular drill. The main thing is that this drill has a reverse. This will allow, if necessary, to quickly unscrew any self-tapping screw or screw.

In addition to the tool kit, it is also necessary to prepare the covering material. For most door panels, you can use leatherette. As a rule, such a product, in addition to good characteristics and wear resistance, has a fairly attractive appearance. Therefore, you won’t want, and won’t need, to repair the door leaf for a long time.

How to insulate a wooden entrance door - Preparatory work

To insulate a door leaf with your own hands, you should strictly follow it step by step, step by step. This approach, as practice shows, allows you to immediately achieve good results and eliminate common mistakes.

For high-quality thermal insulation of an external door, it is first necessary to carry out preparatory work. To do this, so that nothing interferes with further work, you need to remove the door leaf. A similar action is performed using a mounting tool or a nail puller. You need to pry the canvas from below and it will rise from its hinges. Then, with a slight forward movement, move it to the side and remove the door leaf.

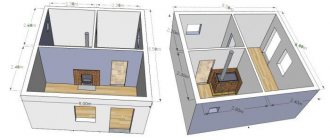

Entrance door insulation scheme

When the door is removed and is outside the frame, all existing elements must be removed from it. The hinges, handles, peephole, building (apartment) number and lock are carefully unscrewed and put aside. If the door has additional extraneous cladding elements, then in order to gain access to the interior of the door leaf, they must be dismantled.

Methods of insulation in an apartment or private house

There are several methods of insulation. Which one to choose depends on the type of structure and its location. Doors facing the street need more thermal insulation, and drafts will require the installation of a second panel.

Along the perimeter of the opening: sealing cracks in the door frame

For this installation method, you will need a sealant that is glued to the sealant or adhesive layer. To seal cracks in the door frame, you can use different types of sealant:

- Foam rubber is the most fragile of all. This material will last no longer than one season.

- Rubber - mounted on a rubber layer and has good operating characteristics.

- PVC - withstands temperature changes well and comes in various shapes. To install this material, you will need to make a groove in the doorway and use a screwdriver to push the PVC tape into it.

- Rubber is a fairly elastic and frost-resistant material.

The more elastic the seal, the more tightly it will be placed in the space of the doorway, ensuring that it is not blown through.

To measure the size of the seal, take regular plasticine, wrap it in a bag and place it in one of the cracks, and then close the door. You will receive a cast from which you can easily select the material of the desired configuration.

There are two ways to glue the tape:

- if the product is self-adhesive , then before gluing, degrease the door frame, remove the protective film and secure the seal from bottom to top;

- if there is no sticky base , use liquid nails or silicone sealant.

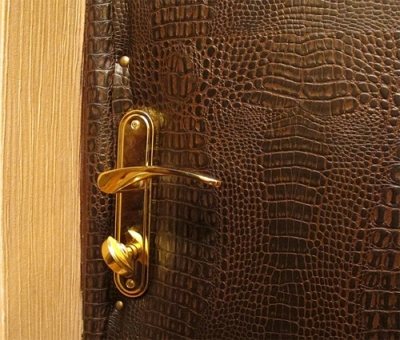

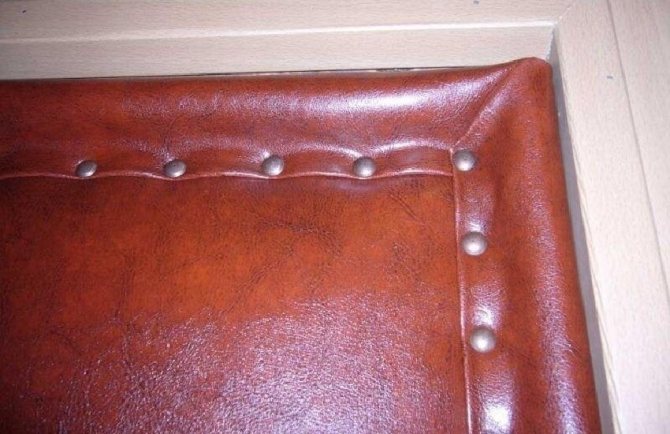

Upholstery

Insulation of the door leaf itself is especially important for metal structures. The procedure is as follows:

- We remove the canvas from the hinges, remove the removable fittings (handles, lock).

- We fasten the insulation with a furniture stapler every 15 cm.

- Upholstery with decorative material, secured with decorative nails.

- We return the canvas to its original place.

Don't forget to leave 5 cm of upholstery material for the hem. For upholstery use:

- skin;

- foam;

- bologna or leatherette.

The material is attached with liquid nails, starting from the top.

You can insulate in another way:

- We attach wooden slats along the edges of the canvas;

- We lay a layer of foam plastic between the slats;

- We decorate the structure with plastic or fiberboard.

Threshold

The threshold protrusion performs several tasks at once:

- closes cracks at the bottom of the door;

- provides thermal insulation;

- prevents the formation of condensation.

You can insulate the threshold in two ways:

- If the protrusion is made of plastic, use polyurethane foam . The structure is removed, the assembly seam is cleared of debris and filled with foam in several layers, then returned to its place.

- Installing a thermal damper. With this method, the threshold is also dismantled, and a heating cable is laid in its place. To control the mechanism, the thermostat is taken outside, and at the end of the procedure the threshold is set back.

We recommend: Installing a instantaneous water heater with your own hands: step-by-step instructions

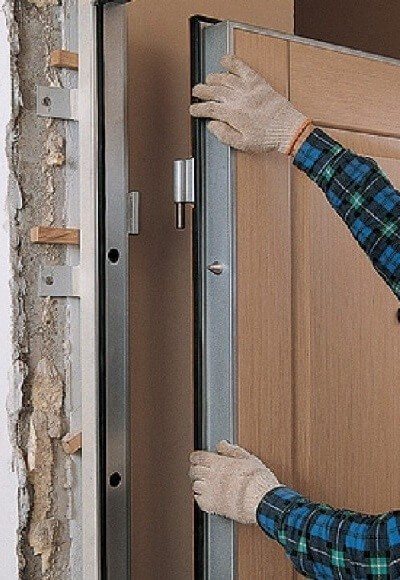

Installation of the second canvas

In private houses and cottages, double doors are especially relevant. Installation of the second canvas is possible in two ways:

- On an existing door frame . This option is convenient when installing panels at the same time, as well as when the structures are made of the same material. Significant advantages of this technique are increased installation strength and speed of installation work.

- Separate installation - relevant when it is necessary to install a second leaf to an existing one or if the doors are made of different materials. To install an additional door, you need to assemble the box, then hang the canvas on it using a building level, and carefully seal it. The main condition for this is that the canvases must be identical in size.

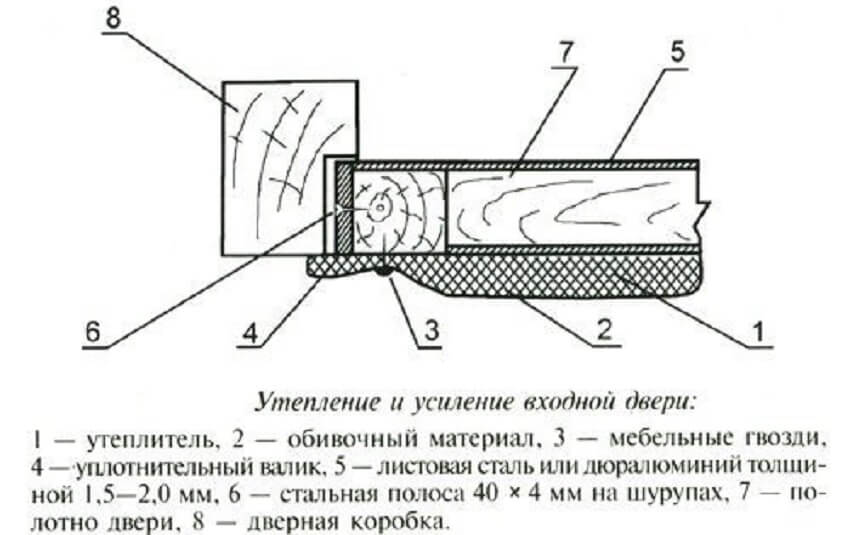

Insulation of metal (iron) and wooden sheets

Heat loss can occur through the door leaf itself, as well as due to loose fitting of the doors to the door frame. Therefore, insulate the structure in two directions. The insulation of a door leaf depends on the material it is made of:

- Metal structures are sealed by filling the cavity inside the door frame with foam or cotton wool. The door must be opened, the cardboard filler removed and the void filled with insulating material, decorated with MDF panels or plastic.

- Wooden doors are sealed with flexible insulation. Since it is impossible to place insulation inside, the doors are sealed from the inside or outside. The location of the hinges and the direction in which the door opens are taken into account. The laid material is covered with film, then upholstered with leatherette, which is attached to decorative nails.

Important: The thickness of the insulation must correspond to the thickness of the door leaf. Otherwise you will have to change the locks.

Insulation of the entrance door opening includes insulation:

- door frame;

- door slopes.

In the first case, a polymer or foam sealant with an adhesive base is used. The tape is attached to a previously degreased surface.

The procedure for sealing slopes:

- dismantle the structure;

- we fill the vacated space with foam and lay soft insulation;

- We return the slopes to their original place.

The main mistake when installing a door frame is the use of low-quality foam, blowing it intermittently, leading to the penetration of drafts. To check if the foam is leaking air, simply hold a lighter to the mounting seam: if the flame fluctuates, replace the insulating material.

Insulation of entrance doors is necessary for comfort in the house and apartment. All work must be carried out comprehensively. The main task is to choose the right material for thermal insulation and follow the instructions proposed in the article.

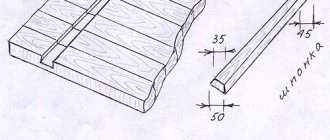

Cutting and laying insulation

The next stage of professional insulation of the door leaf is the laying of thermal material. It will make the door warmer. To do this, you need to arm yourself with a stationery knife. The heat product is cut according to the length and width of the canvas, so that there is no empty space left. If the door has a frame with voids, then they must be filled with insulation.

Laying insulation in the door leaf

All pieces of insulation must be tightly inserted between the bars. This approach will eliminate the formation of cold bridges. At the same time, the thermal material should not bubble or protrude. If this is observed, then this indicates an excessively large supply. In this case, it is worth cutting off the excess a little. Once everything is adjusted, you need to secure the insulation with staples. Quickly and efficiently, allows you to fix it with a construction stapler.

The main features of felt for thermal insulation

It must be said right away that felt is often used to insulate wooden houses. It is in this case that the material demonstrates good efficiency. If we use felt in other conditions, then it will also show itself from a good side, but there will also be some flaws, which we will talk about a little later.

Many builders consider the strength of felt to be the absence of the need for additional treatment of the surfaces of the home. This significantly shortens the entire repair process, and also allows you to forget about the integrity of the finish, which can collapse in various situations.

Due to the fact that this insulating material is relatively inexpensive, it can be laid in several layers. This will also increase the efficiency of the felt, and at the same time we will save a lot of money by not having to buy modern thermal insulation materials.

Unfortunately, felt cannot be used in all climatic conditions. You should first learn about this from specialists who offer felt products. In this regard, the material is more demanding than others.

New door trim

Next, the next step is the upholstery of the prepared wooden doors. For this purpose, you can use soft building materials. As a rule, this is a leather substitute or dermantine. This material is cut with a margin of at least 10 cm in length and width. This is required for the hem, which should have a slight thickening, along the entire door leaf.

Door trim with dermantine

As practice shows, it is best to fix dermantine using special nails. They have a large decorative cap, which gives the trim a more interesting, attractive look. For better fixation, you can run copper wire along the nails. In addition to the unique aesthetics, this approach will allow for additional fastening for both insulation and exterior finishing.

An analogue of soft finishing materials is MDF. This type of finishing is usually used for frame panels. In this case, each cladding panel is attached to a clamp and is punched around the perimeter with nails.

Advantages of using felt for home insulation

This material is used both in housing construction and in mechanical engineering, the creation of ships, the production of filters and various seals.

What qualities made felt so popular?

- This is an environmentally friendly, truly natural material, completely harmless to humans . No synthetic insulation can boast of this quality to the same extent as felt;

Important! Expanded polystyrene, Poneplex, polyurethane foam - all these materials burn, emitting toxic smoke. Mineral wool is often impregnated with phenol-formaldehyde resins, which are hazardous to health. Felt insulation does not have these disadvantages.

- Insulating walls with felt provides very reliable protection from cold and drafts . Our distant ancestors knew about this, using it to eliminate cracks in wooden houses. Natural felt does not allow foreign odors to pass through, it easily absorbs moisture and just as easily releases it back. Vapor permeability protects the house from dampness and mold;

- It provides excellent sound insulation, allowing residents to enjoy peace and quiet . Coarse wool felt is used for sound insulation not only in residential buildings, but also in industrial premises and even in car interiors, which allows us to judge its effectiveness.

Soundproofing felt mats

With all this, felt is a renewable resource, the production of which does not cause the slightest harm to the environment. If you want to build a truly environmentally friendly home, the best choice among thermal insulators is natural felt.

It lends itself well to processing, it is easy to attach it with your own hands, and additional costs will be minimal. In this regard, it is much more economical than other materials.

Another significant advantage is the low price. A roll of insulation is enough for several crowns at once when building a wooden house, and in itself it will cost significantly less than synthetic building materials.

Hang the door - Installing hinges and fittings

When the thermal insulation work is completed and the door leaf has received a new appearance, it is necessary to install the removed fittings in place. The hinges must occupy their nests exactly as they were installed before the start of all insulation operations. The seat for the lock must be carefully cut out so that there is no damage to the door trim around it.

To directly hang the door itself, you need to perform certain, simple steps. The lower part of the hinge, as a rule, contains a pin on which the door with the upper fragments must be placed. Place the canvas in the open position, lift it and put it on the hinges. If, however, it is not possible to lift the door leaf, then install detachable hinges with a removable rod. You need to pull the rod out of the hinge, connect the two parts of the fittings and insert the rod into place.

Before hanging the door, it is recommended to lubricate the parts with machine oil or grease. If the loops are too deep, special pads are installed under them, based on rubber or thick cardboard. If there is a problem with the door leaf being too low, then to raise it, you should install washers between the canopies.