Abashi or Abacha is another name for African oak. This is a valuable type of wood with a strong and at the same time soft structure. Thanks to the ecosystem of the western forests of the African tropics, the properties of the abacha tree are unique. The Finnish and Swedish peoples were among the first to pay attention to them. They began to use the material for interior decoration of saunas. After all, it practically does not accumulate heat.

Features of Abashi

General information

Abash is a giant tree that grows in the equatorial forests of Africa. The height of the tree reaches 40 meters, and the thickness of the pillar is three meters. There is a crown only at the very top, so the trunk is free of knots, which pleases carpenters and joiners.

The color of the wood can vary from straw yellow to creamy white. There is no sharp difference between sapwood and heartwood.

Wood appeared in our country in the 90s. Despite the fact that the price of the material is quite high, it quickly became popular.

It should be said right away that abashi is for a bathhouse what mahogany is for a home. In other words, this is an elite material that costs much more than traditional types of wood. Its high cost is primarily associated with its place of growth, since the route from tropical Africa to our country is not close.

The “bath” qualities of abasha were accidentally noticed by Finnish experts, who noticed that the boxes made of this wood, which contained the equipment, did not heat up at all at a sufficiently high temperature. As it turned out later, this breed really has special properties.

Abashi trunk

Properties of wood

The main property of abashi is the low thermal conductivity of wood. Thanks to this, the boards will not burn a person in a bathhouse or sauna.

But besides this there are many other useful properties:

- When heated, the material does not release resinous substances.

- Resistant to various mechanical influences.

- It does not deform for a long time.

- When indoor humidity reaches 12 percent, the wood remains dry. Even from the ends, wood slowly absorbs moisture. Aspen boards get wet more actively.

- Lumber is not subject to shrinkage.

- Despite the fact that abash has a high density, the wood lends itself well to processing, so it is not difficult to work with it yourself.

- Screws go into wood well. You can even hammer nails without fear that the material will crack.

- In room decor, abash goes well with other types of wood.

- Excellent tinting.

- Does not change color even with prolonged use.

Another interesting property of this wood is that as soon as the human body touches it, the wood immediately takes on its temperature.

Advice! Abashi wood can be used not only for baths, but also for interior decoration of the house. Due to the low thermal conductivity, a house finished with this material will be cool in summer and warm in winter.

The technical characteristics of the abashi are also impressive:

- The maximum load when applying pressure is up to 280 kg per square centimeter.

- The maximum bending load is up to 528 kg per square centimeter.

- Density – 390 kg per cubic meter.

Flaws

Abash has very few disadvantages:

- The main disadvantage of the material is its high cost.

- A small amount of good quality wood is supplied to the market. Since Africa is a very turbulent continent, the regularity of supplies leaves much to be desired.

- The area where trees grow is actively declining.

In the photo - abashi lining for finishing a bathhouse

Abashi - material for finishing saunas

For the first time, the unique properties of abasha as a material for interior decoration of saunas were discovered by Scandinavian builders in the seventies of the last century. The fact is that the relatively small specific gravity and porous structure, on the one hand, and sufficient hardness and elasticity, on the other, reveal the main trump card of this species, namely low thermal conductivity, due to which the wood does not burn the body. Of course, if the temperature in the sauna exceeds 100°C, then at the point of contact between the air and the wood, the latter takes on the air temperature, but thanks to the porous structure, heat does not accumulate and, as soon as you touch the wood with your body, it instantly takes on your temperature. Therefore, sauna shelves are most often made from abasha.

I would like to emphasize that with 12% humidity, abashi is actually a dry material, i.e. will never sit down, will not go “screw”. Conventional materials (spruce, aspen), traditionally used in saunas by Finns, have a much higher humidity (from 30%). Thus, it is difficult to refuse Finnish builders and designers the advisability of using abashi in the decoration of saunas.

Abashi is native to the rainforests of West Africa and is known in international trade under various local names: "obeche", "wawa" (Ghana), "ayus" (Congo, Cameroon), "abashi", "samba" (Côte d'Ivoire) . The wood ranges in color from creamy white to straw yellow; There is no sharp difference between heartwood and sapwood. The density of freshly cut wood is 550-700 kg/m3; density at humidity 12%: 370 kg/m3. Specific gravity 0.25 - 0.55. g/cm2 Withstands bending loads up to 530 kg/cm2, and at pressure up to 280 kg/cm2.

Abashi grows in tropical forests as a free-standing tree; There are practically no thickets of abashi. Reaches 40 meters in height and 2 - 2.5 meters in diameter. The crown is only at the top, which determines the virtual absence of knots. Abashi wood is easily processed by hand and on machines, peeled into veneer and glued well; You can drive nails and screws into it without the risk of splitting. Perfectly tinted. All of the above qualities make abashi a high-tech material. To the chagrin of sauna lovers, all of these features were first noticed by European manufacturers of interior profiles, who for many decades, starting from the 20s of the last century, exported huge volumes of abasha mainly from Cote d'Ivoire, using it for the production of furniture elements and framing ram.

Despite the fact that abashi exports have declined significantly in recent years, such rampant logging without subsequent restoration has led to the fact that in many areas of this West African country, to which transport routes are built, abashi has practically disappeared. Significant quantities of abashi remain in the Congo, but the unstable political situation in that country makes exporting timber from there not only difficult, but also dangerous. Certain reserves of Abashi exist in Ghana, whose authorities, by the way, have begun to take measures to artificially restore this breed.

The situation is further aggravated by the fact that after felling the tree must be sent to dry for 1-2 days, otherwise the sapwood quickly turns blue and even black spots appear. To this we must add that long rainy seasons make year-round felling impossible. Abashi appeared in Russia in the mid-90s, and connoisseurs of bathing immediately fell in love with this material, primarily for its delicate light shades and uniform texture, as well as for a wide range of profiles, giving unlimited scope to the imagination of designers, high technology in the carpentry process processing, durability and the ability to maintain the appearance unchanged for a long time and, of course, for the “non-burning” effect.

Later it was noticed that abashi goes well with other types of wood, especially with the contrasting Canadian cedar. The abundance of profiles makes it possible to manufacture various accessories, as well as exterior decoration of saunas, relaxation rooms and the production of furniture elements.

Traditionally, in Russia, Finland, and Sweden - the most “bathed” countries - only those types of wood that grew in this region were used for interior decoration: pine and spruce. Unfortunately, the natural solution is not always the smartest one. Both pine and spruce are knotty trees, and when heated, the knots release resin that is harmful to health. In addition to conifers, aspen or linden are also used, however, these materials also have their own problems. Linden is a low-tech tree, making boards from it is difficult, and good quality material is irrationally expensive. Aspen has a nondescript whitish-gray color and quickly loses its already unpresentable appearance.

It is unlikely that in previous centuries, Siberians and other lovers of steam baths would have guessed that it was in distant Africa that trees grew and were waiting in the wings, the baths from which would become so close and dear to the Russian steam bather that without them it would be impossible to imagine the process of steaming. Let's hope that constant cataclysms in West African countries will not call into question the supply of abasha to Russia, and millions of connoisseurs of saunas and baths will not be deprived of their pleasure, since today it is as impossible to imagine a sauna without African abasha wood, as it is impossible to imagine Paris without the Russian "Maxim" .

How to make shelves from abasha

So, the wood of the species in question is used in baths and saunas as cladding, as well as material for shelves and bath furniture. The sheathing can be purchased in the form of lining, but you will have to make the shelves yourself from boards.

Before you start making them, you should make a drawing of the future design.

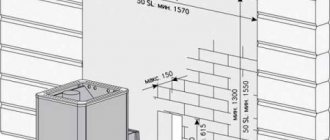

The dimensions of the shelves should be taken into account:

- The minimum length of the bench should be 150-180 cm;

- Height - at least 20 cm from the floor and at least 40-60 cm between levels. The distance between the ceiling and the upper bench should be at least 100-120 cm.

- The width can be from 40 to 150 cm, depending on the size of the steam room and the preferred resting position.

Frame for shelves

Advice! Before making the structure, boards and beams should be carefully sanded and sharp corners smoothed.

The instructions for making shelves for a bathhouse are extremely simple:

- First of all, you need to assemble the frame. To do this, you need to make several support posts from timber with a cross-section of 50x70 mm, install them in a vertical position and fasten them horizontally with strapping. To prevent the flooring from sagging, the racks should be installed at a distance of no more than 50-60 cm.

- Then you need to make benches from thin abashi boards, nailing them to the frame with a gap of several centimeters. To ensure free flow of water, benches should be tilted at one to two degrees.

Note! It is prohibited to use synthetic antiseptic compounds for treating wood, since harmful toxic elements can evaporate under the influence of high temperatures.

The parts should be connected using wooden wedges, which are driven into pre-prepared holes. When using traditional self-tapping screws, they are deepened into the wood to a depth of 5-6 mm to prevent the possibility of burns.

Two-tier benches

LLC "Corporation Agroles" wholesale and retail sale of woodworking products in Tyumen

There probably isn’t a bathhouse lover who hasn’t at least heard about the African miracle tree abash. So much has been said about its extraordinary properties, it has been shown that for many it has eclipsed our native trees - linden, alder and aspen.

Why is it so good and is it really endowed with the extraordinary characteristics that exotic sellers attribute to it?

Abache, also abashi and abacha, is a deciduous tree that grows in western equatorial Africa, in the countries located between Gabon and Eastern Guinea.

The wood has various shades ranging from creamy white to pale yellow.

The tall, straight trunk of the abasha is a woodworker's dream! Disc-shaped roots extend up to approximately a height of 4-6 m; they help the giant to withstand the onslaught of the “green ocean” of the jungle.

From a wide base, a smooth trunk with a diameter of up to 1.5-2.1 m rises up to 30-35 m. The wood of the tree is from creamy white to light straw color, without any special differences between the sapwood and the core. Density - from 320 to 490 kg/m3 (at a humidity of 12%).

The wood dries quickly and easily, only when laying thick logs you need to ensure good air circulation. After drying, the abash remains resistant to moisture during indoor use.

Anyone who has been even slightly interested in this type of building material knows the story, or rather the legend, about why this previously little-known tree suddenly became so popular.

In short, it’s as if one day they accidentally left a box made of abasha in a Finnish sauna and noticed that the wood, surprisingly, practically did not heat up.

Photo of African Abashi.

The main feature of products made from abasha is poor thermal conductivity combined with low heat capacity. Thus, it is almost impossible to get burned from such a tree. Thanks to this, the manufacture of abash shelves and other items for baths and saunas that come into contact with human skin has become widespread.

Also, the advantages of this tree are its high resistance to water, the absence of resin and knots.

Mechanical qualities include ductility, low weight, sufficient strength and preservation of its appearance and shape over an extended period of time.

This wood is practically not subject to deformation. The unique parameters of abash wood make it an excellent material for the production of both interior decoration and many load-bearing elements of baths and saunas.

In very popular Finnish saunas, 90% of the wooden products are made from abasha. The special properties of abash wood were discovered in the 70s of the twentieth century by Scandinavian engineers and builders.

Abash has a porous structure, thanks to which it acts as a heat-insulating material. It also provides him with low weight. However, this structure has sufficient strength and good elasticity. The combination of these qualities made abash a popular material for finishing baths and saunas.

Now African wood is not exotic. Abashi shelves have become available for ordinary consumers to buy.

Our country has sufficient reserves of linden, aspen, alder, and cedar, the wood of which is used for the construction of shelves in steam rooms. But despite this, traditional materials have been increasingly replaced with wood from Africa in recent years.

The first and most important advantage of abashi is, as mentioned above, its extremely low heating ability, which is why abashi has become widespread as an interesting building material.

Fans of bath procedures note that at sufficiently high temperatures, the steps of the shelves heat up to a lesser extent than other types of wood. This is especially noticeable in steam rooms, where the shelves are made of different types of wood. For example, it is very common to alternate lighter abashi boards with darker alder and thermo-aspen.

Sometimes you can come across statements that African wood does not have such a feature at all and heats up to the same extent as other species. Here we can unequivocally say that these are not Abacha.

The light, light wood of alstonia and cottonwood is reminiscent of abacha. They are cheaper and do not have the necessary properties, so they can be passed off as real valuable wood. The so-called “Asian Abash” (or “Silk tree”). Its distinctive feature is its white-gray color.

The second negative feature of this wood is its swelling and cracking, in some cases falling apart into pieces (like wet cardboard). In Europe, such wood is not used. Due to the illiteracy of a particular buyer, of course they will sell him an Asian abash - much cheaper and worse in construction

Photo of Asian Abasha.

Real abashi comes exclusively from the African continent; unlike the counterfeit, it is not gray, but yellowish in color and has a beautiful pattern of wood structure.

Another advantage is its high grade. The characteristics of wood are such that products made from it are smooth, without defects or knots, and are characterized by uniform texture and color, which together make them very beautiful.

Coming from a hot and humid climate, it tolerates temperature changes well, does not crack, warp or rot, while at the same time having good hardness and elasticity.

Although Abash is sometimes mistakenly called African oak, its wood, which has a porous structure, is easy to process, so no difficulties arise when finishing the steam room.