Many people build bathhouses in their dachas and country house areas.

They have been very popular since ancient times, because they are a great way to restore your health, relax and calm down. But this is also a considerable risk, since the bathhouse is a fire-hazardous structure. Alas, people often die in fire, as can be seen from fire department statistics. Even if there are no casualties, during a fire the owner will suffer huge material and financial losses. Nowadays, a lot of attention is paid to fire safety issues when developing structures and designing buildings. New, improved types of equipment that localize the source of fire are constantly being developed. The rules and fire safety standards are also changing, compliance with which is monitored by a special supervisory service. However, these measures do not guarantee one hundred percent protection from fire, especially when it comes to fire-hazardous buildings such as bathhouses.

A big role in this issue is played by the consciousness of the people operating the bathhouse and their compliance with recommended fire safety requirements.

Fire safety during construction

The first measures to comply with fire safety must be observed already at the construction stage of the facility.

- We must not forget that a possible fire can cause damage not only to your own property, but also to your neighbors’. That is why, when building a bath complex, it is necessary to choose the optimal location for its construction.

- It must be remembered that bathhouses burn for three reasons: incorrectly selected roofing material, illiterate installation of the chimney stove.

- The location for the stove must be chosen carefully - no matter how reliable the masonry is, over time microcracks and cracks may form in it. The stove must be located at a sufficient distance from interior items, especially flammable ones. A reliable foundation and careful alignment of the stove frame will help minimize the number of possible future flaws.

- In front of the firebox door, a metal sheet is laid on the floor along the entire length of the stove, at least half a meter wide. In modern conditions, metal sheets can be replaced with special oven bricks or other materials of equivalent fire resistance.

In those buildings where the structures provide for the adjoining of beams, ceilings and partitions close to the furnace, horizontal and vertical trims made of non-flammable materials are installed to the entire height of the furnace structure using asbestos, clay, and brick. An equally important point is to ensure fire safety of the roof of the building and attic spaces.

Where should the bath be located?

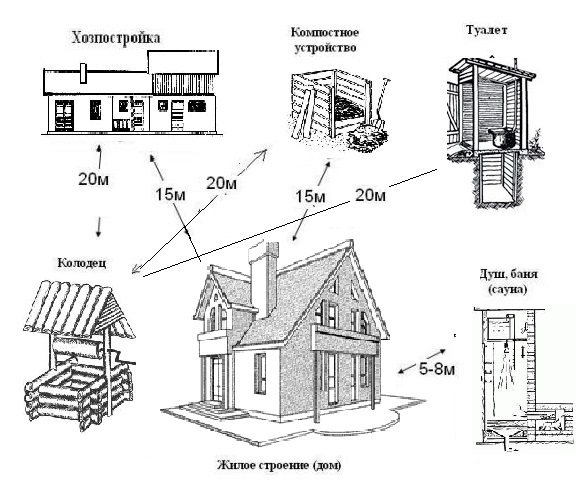

There are certain standards for building a bathhouse on a plot of land, compliance with which is regulated by regulations. Violation of these provisions is highly undesirable and may result in the most severe sanctions from supervisory authorities.

Distances from buildings to the fence

So, there are the following standards for the construction of a bathhouse from a fence:

- According to the standards, the distance must be at least 3 meters, this is due to the peculiarities of draining wastewater from the building. The optimal solution is a separate drain or gutter, in which case the distance to the fence can be reduced to 2.5 meters.

- Any deviations from the norms must be agreed upon between neighbors in writing to avoid problems in the future when the owner of the property changes.

- In any case, the distance to the fence should not be less than 1 meter; this minimum permissible distance must be observed.

You should not save space between the bathhouse and the fence in order to avoid violation of norms and requirements

In addition to the distance to the fence, there are other standards for the location of the bathhouse on the site:

- The distance from the residential building to the bathhouse must be at least 8 meters.

- There must be a distance of at least 12 meters from the well to the bathhouse building.

- If the bathhouse is located on a dacha or garden plot, then the borders of the neighboring plot must be at least 8 meters.

Fire safety during operation

Compliance with fire safety regulations during the construction of a bathhouse complex is only half the battle. When operating a bathhouse, it is also necessary to strictly comply with bathhouse fire safety standards throughout the entire period. The main reasons that can lead to a fire are:

- thermal defects in wood that occur under constant heating and lead to spontaneous combustion;

- damage to electrical cables due to improper installation or violation of their operation standards;

- mistakes made when laying the stove.

- choice of roofing material: it is undesirable to use bitumen-based roofing materials such as Ondulin, Icopal, etc.)

In order to promptly detect possible defects and prevent a fire situation in time, it is necessary to fulfill certain requirements.

- Before each ignition of the stove, you need to check the presence of draft. If this is absent or insufficient, then you should initially try to heat the stove using a small amount of wood chips or wood shavings. When the above manipulations do not lead to the desired result, then there is only one way out - to clean the chimney. Chimney cleaning should be carried out regularly, since combustion product waste - soot, soot, ash - accumulates in the passages and channels of the pipes during operation. You can clean the furnace ducts yourself:

- you can heat the stove with aspen wood; they are an excellent means of cleaning soot from chimneys

purchase a pipe cleaner in specialized stores, throw a bag of the product into the melted firebox on top of the firewood, the evaporated chemical substance dissolves the soot on the walls of the chimney and the furnace firebox

- While using the bathhouse, you must regularly monitor the condition of the stove masonry. Having discovered cracks, it is necessary to immediately repair them, without postponing repair work. Gaps in the stove frame can form not only due to improper masonry, but also from the use of low-quality materials, such as: low-grade stove mixture, cheap stove bricks, building bricks - not suitable for stove masonry

*If the chimneys are heavily soiled, it is necessary to call stove installation specialists who will perform mechanical cleaning of the chimneys by disassembling the chimney system.

If the brickwork is laid without observing safety measures, then the risk of overheating and cracks is very high.

Possible fire situation

After the wooden doors in the steam room burn through at the initial stage of fire development (if the fire is located near the doorway) or when they are opened during the process of extinguishing the fire, an intense influx of air oxygen from the adjacent rooms occurs, leading to the creation of an explosive concentration of a mixture of gases and vapors (5 -40% of the room volume). At a wood burning rate of 0.6-1.0 mm/min, destruction of the door leaf occurs, as a rule, 20-30 minutes after flaming combustion occurs in the steam room.

Intensification of the process of air intake leads to the rapid formation of a flammable mixture, its self-ignition or ignition with the possibility of volumetric combustion or explosion.

Due to the increase in pressure from the combustion of the mixture, part of the volume of the mixture with a concentration above the upper limit is released from the steam room into the corridor (dressing room) and other adjacent rooms, which, when mixed with air, ignites outside the steam room. This creates a spreading flame front with a temperature of about 1000 °C, leading to the rapid spread of fire and combustion products throughout the building.

An outbreak (explosion) of the products of thermal decomposition of wood is also possible in rooms adjacent to the steam room when a fire escapes there, followed by attenuation due to insufficient air exchange, or when the gas-air mixture infiltrates into these rooms through leaks in the door vestibule of the steam room.

If the steam room at the time of the fire had proper supply and exhaust ventilation with open adjustable dampers, the combustion process there will proceed more intensely, with the forced release of combustion products through the exhaust ventilation duct with a natural flow of air into the room.

Due to chemical underburning due to the insufficient amount of oxygen for an intensive combustion process, the afterburning of the products of incomplete combustion of wood will occur in a torch when the gas-air mixture is released through the ventilation duct. Opening the entrance door to the steam room of the sauna, in this case, will not result in an explosion of pyrolysis gas.

Why are cracks dangerous?

- carbon monoxide may enter the premises, which poses a huge risk to human health, including death;

- cracks are fraught with the release of sparks and small embers, which can cause a local fire and further fire throughout the entire structure.

Note! It is strictly prohibited to use liquid substances as heating fuel. Lighting with liquid fuel can lead to sudden bursts of large amounts of fire, which will cause damage to the premises and the health of others.

Sanitary requirements for the construction and operation of a bathhouse

As is known, sanitary standards for baths affect mainly public institutions, while structures for personal use are affected much less, which often leads to violation of various norms and rules that affect the quality of recreation and safety of operation.

Basic sanitary standards for the construction of buildings on the site

What needs to be considered during the construction process

- The instructions for a public bath pay great attention to a high-quality ventilation system; this is no less important in small buildings, because the durability of the structures and the quality of their drying directly depend on this. In addition, musty air is not conducive to a good rest in the steam room.

- The installation of high-quality drainage is also important; defects can lead to the appearance of fungus and the proliferation of various pathogenic bacteria.

Advice: you should not skimp on materials for thermal insulation of the steam room; the durability of the structure and the quality of ventilation directly depend on them. The low price of insulation is the first indicator of its low quality.

Why compliance with sanitary and building codes is so important

During construction, first of all, it is necessary to take into account all the features of the project. It is worth understanding that compliance with all standards is intended to ensure the maximum level of safety during operation, as well as ensuring the best quality of rest. Any deviations can reduce the benefits of bath procedures and make staying in the steam room dangerous.

Fire safety in the bathhouse (sauna)

Finnish baths with a dry steam room, known as saunas, are no less popular than Russian baths with moist air. Electric heating stoves are standardly installed in saunas, but this does not make the fire safety requirements for them any more lenient. When building a sauna, the following standards must be met:

- the maximum area of the sauna does not exceed 5-10 sq.m.;

- the distance to the walls from the electric furnace is at least 0.2 meters;

- the height of the steam room is limited to 2 meters;

- the temperature in the sauna cannot exceed 110 degrees.

A protective thermal insulation coating is installed above the electric stove, protecting the ceiling from overheating and fire. Thermal protection should not be located close to the ceiling surface. It is necessary to leave a distance of several centimeters between the coating and the ceiling. All electrical wiring elements must be insulated with fire-resistant materials.

Coniferous wood is not used for interior decoration of saunas and bathhouses in order to avoid the release of resinous substances when heated. The fire safety of a bathhouse built like a Finnish sauna requires natural ventilation with fire-retarding valves. Modern saunas are also equipped with automated fire control with smoke alarms. Automatic ovens automatically switch off when the maximum temperature is reached and after a certain number of hours of operation.

If you comply with all fire safety standards regarding the proper construction of a bathhouse and its further use, you can ensure proper relaxation in the steam room for many years.

Safety precautions when extinguishing

To successfully fight fire when eliminating fires in the steam rooms of Finnish-type baths, you should:

- study fires in bathhouses and saunas from an operational-tactical perspective, paying special attention to the practical training of combat operations;

- draw up operational cards for each bath-sauna indicating on the plan the placement of premises, sauna equipment control points, ventilation openings and control units (connections) of stationary fire extinguishing systems.

In order to eliminate the danger of an explosion in the process of extinguishing a fire when an explosive concentration has been created, before entering the steam room where the fire is located, it is necessary to take measures to actively ventilate the premises, freeing them from smoke and wood pyrolysis products. It is recommended, in particular, to blow out a burning room with superheated steam. When 1 liter of water evaporates, about 1700 liters of steam are formed, therefore, to purify a steam room with a volume of 17 m3, it is enough to evaporate 10 liters of water in it. In this case, water must be supplied to the steam room in a finely sprayed form from trunks of the RS or NRT type through a window or other small opening when the trunkers are at a safe distance from the doors. A positive result is also achieved when using air-mechanical foam of medium expansion for these purposes.

Methodological recommendations of the All-Russian Institute of Technical Safety of the Ministry of Internal Affairs of Russia, in order to maximally eliminate accidents when extinguishing saunas, it is recommended to take measures to prevent the possibility of the formation of a flammable explosive concentration of the gas-air mixture at the time firefighters enter the building.

To maximally eliminate accidents when extinguishing saunas, it is necessary to prevent the possibility of the formation of a flammable mixture at the moment of entry into the building.

Basically this can be done in two ways:

1) phlegmatization of volume;

2) preliminary initiation of flaming combustion in the steam room to reduce the concentration of flammable gases below the LEL.

To phlegmatize the volume, the most effective is fire extinguishing powder supplied into the steam room volume through a small opening: a window, a ventilation slot, etc.

The powder will remain in suspension for a time sufficient to open the door and supply the barrels for cooling, preventing ignition and the spread of kinetic combustion. Preliminary initiation of flame combustion or reduction of concentration below the concentration limit with simultaneous cooling of the volume can be carried out by supplying air into the volume using a smoke exhauster.

As additional measures to ensure work safety, the following recommendations should be followed:

- carry out exploration and opening of saunas in the presence of a hose line filled with water with trunks creating a water curtain;

- inside the steam room above the entrance door, install a sprinkler (a normally closed sprinkler that automatically opens when a certain temperature is reached due to the destruction of a low-fusible lock) with an operating temperature of 180 - 220 ° C, powered from the water supply network.

If a fire occurs, the sprinkler will turn on at the stage of flaming combustion or even earlier, which will reduce the intensity of the fire and ensure phlegmatization of the volume with water vapor. In this case, the water curtain created by the sprinkler in front of the front door will act as a kind of fire arrester in the event of a steam-air mixture being released from the steam room.

Instructions on fire safety measures in dry heat baths (saunas) are available by clicking the DOWNLOAD

Some of the information is taken from the order of the Ministry of Internal Affairs of the Republic of Belarus dated July 9, 1996 No. 140 “On approval of the Fire Service’s Combat Regulations”, the other part from the methodological recommendations of the All-Russian Military Training School of the Ministry of Internal Affairs of Russia, as well as experience in fires and exercises.

During the construction of buildings

According to the requirements of SP 48.13330.2011:

- The demolition of buildings and structures existing on the construction site is carried out in accordance with the project for the organization of work, based on decisions that ensure the safety of workers and the population; and also taking into account the presence of existing underground communications, including electrical routes, gas pipelines, external fire water supply networks.

- Combustible building structures and materials must be removed; burning them on the construction site is prohibited.

- Temporary buildings and structures intended to meet construction needs are installed and erected on the site, taking into account the preservation of the provided fire breaks, and after completion of the work are subject to removal or demolition.

- Preference is given to mobile/inventory temporary buildings, factory-made structures that comply with fire safety standards, rules that apply to construction facilities for administrative, industrial, warehouse, and residential purposes.

Conclusion

Having studied the regulations indicated in the article and applied in practice all the requirements described above, you can easily cope with both the design and the tedious process of coordination and approval of the project. Only after this can you proceed directly to construction work (see also the article “Construction of a bathhouse: features and recommendations”).

The video in this article will help you understand this issue even better.

Capital construction of buildings of any functional purpose, height, area requires design that takes into account all aspects of the construction of the facility, including issues of ensuring the safety of people in case of fire both at the construction stage and during further operation.

Despite the fact that capital construction projects often differ greatly in many respects, each project, according to Decree of the Government of the Russian Federation No. 87 of February 16, 2008, must contain section No. 9 “Measures to ensure fire safety.”