Types of floors in the bathhouse

From this video you will learn how to build a bathhouse and how to make floors in it.

Enjoy watching!

Concrete

For foundation construction, one of the most popular materials is concrete.

Concrete floors are usually made in the steam room and in the washing department, as well as in large baths made of brick.

That is, such a coating is ideal for those rooms where there is constantly high humidity.

Because concrete is not afraid of dampness.

And over time, under the influence of moist air, it becomes stronger and more durable.

This floor is not afraid of rotting.

It is very easy to care for.

Wooden

To construct wooden bases in a bathhouse, coniferous wood is used:

- fir;

- larch;

- spruce or pine.

Coniferous trees have a higher resin content in the wood, which will make the service life of the wooden base longer.

When wet, this coniferous floor does not slip as much as an oak floor.

According to the design, wooden floors in the bathhouse are made leakable or non-leaky.

tiled

Everyone knows that a bathhouse is a room in which there is very high humidity and sudden temperature changes.

Therefore, special requirements are placed on materials for finishing baths.

If in the steam room and washing areas it would be best to put wood on the floor, then the ideal material for the vestibule, shower and rest room is definitely tiles.

The tile is exceptionally resistant to temperature changes and moisture.

It is very easy to clean, and the tile is absolutely safe for the human body.

Advantages and disadvantages of ladders made of different types of wood

Regardless of the material from which the floor in the bathhouse or sauna is made, a removable wooden grating is usually placed on top of it. This coating provides a hygienic barrier, allows you to avoid injuries (after all, it is easy to slip on a wet concrete or ceramic floor), and it is more pleasant to walk on wooden gratings - ladders - than on cold tiles. The ladders are easy to clean and can be taken out at any time to dry or for antiseptic treatment.

Traps are made from various types of wood, each of which has its own advantages and disadvantages.

Larch . This is the best option; it can easily withstand conditions of high humidity and significant temperature fluctuations, is not affected by pests and fungus, and does not rot. However, its cost is significantly higher than other types of wood, which, however, is compensated by its high practicality and long service life.

Cedar . It is also an excellent, very aesthetic material, from which not only ladders are made, but also bath utensils, furniture, and is used in interior decoration. The material is durable and resistant to external influences. Like larch, it is little susceptible to fungal and insect damage. Cedar wood can even disinfect the air in the sauna room, which prevents the spread of respiratory diseases.

Linden . A material that is affordable and quite suitable in its characteristics, widely used in the construction of baths and saunas. Belongs to soft breeds. Despite its relatively low cost, linden wood also tolerates high humidity well and has natural antiseptic properties that protect it from fungus. Another advantage of this material is its pleasant velvety surface; it is easy to process and sands well. If the linden ladder is dried in a timely manner and thoroughly, the wood will not darken or turn black for a long time.

Aspen . Its characteristics are similar to linden and can also be used to make bath drains at an affordable price. An aspen ladder, as in the case of linden, requires good drying after use to avoid blackening of the wood.

Pine . Its advantages are availability and low price. In a steam room, a pine ladder is unlikely to last long, but as a temporary and economical solution (for example, seasonal use), this is a very good option. But you need to remember that pine is a coniferous tree; its wood contains resin, which can be released when heated.

Any wooden bathhouse ladders require proper care. In addition to mandatory drying in a well-ventilated area or in the open air, you should regularly apply moisture-proof impregnation and treat them with a disinfectant composition.

Installation work

In this video we will talk about thermal insulation: how and why it needs to be installed.

Let's watch and remember!

Construction of concrete foundations

Fill the floor with soil:

- Work begins with removing the plant layer. Then you should pour a layer of gravel and compact it. You should install a sewer pipe in advance, to which you can then connect the entire sewer system of the washing department of the bathhouse.

- Then a sand cushion is placed over the compacted layer of gravel and everything is thoroughly compacted again. The optimal thickness of the sand cushion is 40 cm.

- We place a waterproofing layer on top of the carefully compacted sand. To do this, they usually use ordinary roofing felt or other rolled materials that prevent the penetration of moisture.

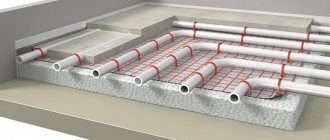

- We lay a layer of insulation on the waterproofing. This can be either mineral basalt wool or expanded polystyrene. Just like waterproofing, the insulation should be folded upward. This ensures protection of the base in the bathhouse from the cold that will penetrate through the base.

- Before pouring, the base must be reinforced. To do this, we use a mesh made of wire 5 mm in diameter.

- We make a screed on top of the mesh. We lay the solution in a layer of 30 mm, making a slight slope to drain the water.

Option for a concrete floor in a bathhouse.

The second method of constructing a concrete base with pouring along the joists:

- The logs are made from timber with a cross section of 100x200 mm. The distance between them should be 50 cm. Bars are nailed to the joists, onto which the subfloor is laid from boards 30 mm thick.

- It is necessary to spread a layer of waterproofing on top of such a base. Any insulation roll material can be used.

- We lay a reinforcing mesh on top of the waterproofing.

- Fill the concrete base with a layer of 30 mm.

Installation of a wooden floor in a bathhouse

First, let's look at a leaking wood floor.

From the very name of the base it is clear that the boards are laid so that water flows between them:

- We start installing such a floor from the ground under the bathhouse. If there is soil there through which water can freely pass into groundwater, then there is no problem. If the soil is clay, then this is a problem. Then they drain the water. A gutter is dug through which water is drained into a septic tank or drainage pit. A gravel cushion is poured on top. The distance between the bottom of the beams and the ground should be at least 30 cm. This is required for ventilation.

- Now we install the logs. Since the floor leaks, we lay the logs on the same level without a slope. You can install logs from any wall in any direction. Install the beams so that there is a gap between the walls and the joists. All wooden elements are treated with antiseptics and covered with waterproofing.

- Now you can directly begin laying the floor. The boards should be prepared in advance to the required size. Their length should be slightly less than the length of the floor to create a gap for ventilation.

- The first board is secured with nails to the wall surface. The nails should be as long as twice the thickness of the board. Drive the nails in at a slight angle. 2 nails should be driven into each joist.

- The second board is laid nearby, but leaves a gap. Approximately 3 mm. She is nailed down. This is how all the boards are laid.

How to attach plastic skirting boards? Read on our website.

You can learn about the construction of a wooden floor using joists here. We recommend this article!

And this article is about how you can insulate a floor using expanded clay under a screed.

Laying a leak-proof wooden floor:

- The soil under the bathhouse is arranged in the same way as for a leaking foundation. Just take into account that the water flow will not pass over the entire floor area, but in one organized place. It is best to use a plastic sewer pipe with a diameter of 150 mm. And don't forget about the garbage disposal grid.

- With this type of base, the logs are laid not level, but with a slight slope towards the drain. Experts recommend a slope of 10 degrees.

- After the logs are laid in place, they must be impregnated with an antiseptic. Then the subfloor is laid. Subfloor boards should be impregnated with drying oil. This floor is the basis for a layer of insulation.

- Now we arrange waterproofing. To do this, we lay roofing material or parchment on the subfloor. Next we install the insulation. In most cases - polystyrene foam. We lay another layer of waterproofing on top.

- For the finishing base we use a tongue and groove board. After all, a tongue and groove is an ideal hydraulic lock. Before laying, the board is impregnated with an antiseptic.

- On each side you should move 2 cm away from the wall to create a ventilation gap. The first board is laid tongue-and-groove against the wall. The second board is inserted into the groove, adjusted with a mallet and nailed.

How to make the floor in the bathhouse non-slippery?

The floor is not so important for maintaining heat and regulating the level of humidity in the room. The temperature at the floor level is not too high, so to ensure thermal insulation of the bathhouse, a flooring made of boards or a layer of gravel under a concrete slab will be quite sufficient.

The construction of the floor can be done in various ways, the main thing is to avoid the appearance of large gaps, which can cause drafts. But a warm, beautiful floor will undoubtedly bring more benefits and pleasure. After all, it is very pleasant to walk on a wooden or tiled surface and not feel any discomfort. In addition, doctors do not advise standing with hot feet on a cold floor after getting too hot, as this can cause heat stroke. To avoid this, it is best to cover the floor in the bathhouse with wooden boards, cork mats or mats. In a bathhouse with a concrete floor, anti-slip coatings and Laguna coating will help make the floor less slippery, thereby protecting bathhouse visitors from falls.

Concrete floors in bathhouses are usually made in washing and steam rooms, as they are much easier to clean and do not require special care. But you definitely need to lay wooden gratings on top of the concrete, which are also very easy to wash and dry. The floor in a bathhouse made of wood looks much more beautiful and is more pleasant to the touch. To obtain the required level of moisture resistance and airtightness, wooden flooring is treated with a special solution. And to prevent the accumulation of moisture in the room, the floor in the bathhouse is made at a slight slope. This allows the liquid to flow freely into a special hole in the wall, to which a drainage pipe is connected. The upper wooden flooring must be separated from the lower cold floor. To do this, you need to install rubber gaskets in the corners of the room.

To ensure the safety of visitors, the floor in the bathhouse should not be slippery, but it is better if it has an anti-slip lagoon coating. Also, do not fill the floor of the bathhouse with unnecessary objects that can cause you to trip. But experts consider the Laguna anti-slip coating to be the best floor covering in a bathhouse. In addition, even on the wet Laguna surface you cannot slip . Another advantage of the lagoon coating is its color range; the warm tones of the anti-slip coating will create a calm atmosphere.

If the hard soil is located below ground level, or it freezes strongly during the cold season, then in this case you can equip the bathhouse with a suspended floor. This type of floor has many different types of structures, the choice of which depends on the type of walls, the load exerted on the ground and the frequency of operation of the bath. But all these types of configurations are based on approximately the same principle of floor arrangement.

The design of the suspended floor includes four supports made of wood and with a tongue and groove seam, the usual cutting width is 9 cm. The size of the gaps between the supports can vary from 60 to 90 cm. This distance depends on the thickness of the boards chosen for flooring. For flooring, boards with a width of 1.9 to 2.9 cm are most often used. The supports must be nailed to the joists at a slight slope. To avoid rotting of the wood, the joists and gutter must be treated with an antifungal solution, this will extend the service life of the coating. In the areas where the floor and internal walls meet, it is best to install a special waterproof plinth, while the bottom row of cladding should form a “undercut” under this plinth.

A real bathhouse should not have any serious flaws. And even though the floor is not so important for the main function of the bathhouse, it is still its significant detail. Therefore, when building a bathhouse or during its renovation, try to pay special attention to the floor. A floor of any design and from any material can be beautiful and comfortable if it is laid well.

Read along with this article: Color therapy for baths and saunas Conditions in the bath Baths made of timber Stone for baths Accessories for baths and saunas.