Insulating the ceiling with expanded clay in a bathhouse is environmentally friendly and inexpensive

The bathhouse is a universal place for rest, relaxation and health improvement. It is known that the bath accelerates blood flow and stagnant processes in the body, promotes the rapid elimination of toxins and waste, rejuvenates the skin, and relieves fatigue. However, the entire effect depends on how well the bathhouse is designed.

The ceiling and walls of the bathhouse must be insulated. This is especially true for the ceiling, because it is under the ceiling that the temperature is highest, and when heated, the air becomes lighter and goes into the roof, into the attic and further into the street. As a result, all the energy and all the heat heat the space around the bathhouse, and this is wasteful. If the bathhouse ceiling is poorly insulated , condensation will appear on it. The appearance of condensation indicates that it is necessary to urgently begin the insulation process. It is best to carry out insulation at the construction stage of the bathhouse, because in this case you will not have to disassemble the structure.

Expanded clay is one of the many materials that is often used for insulation. It consists of fired porous clay granules. The unique thermal insulation properties of expanded clay are due to its cellular structure.

Technology

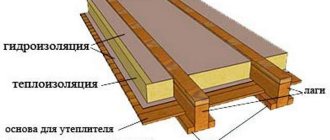

How to insulate a bathhouse ceiling with expanded clay? The technology for insulating the ceiling in a bathhouse with expanded clay is of medium complexity. In principle, anyone who does not have any construction skills can handle it. The insulation is installed from the attic side. First you need to put a layer of vapor barrier material. It will also perform the function of waterproofing.

The current construction market offers a huge variety of options for vapor barriers . These can be modern materials such as Izospan or analogues. You can take regular plastic film, roofing felt and aluminum foil. However, experts do not recommend roofing felt. When exposed to very high temperatures, it gets wet. In addition, roofing felt may catch fire.

The chimney pipe and rafter beams are also laid with a vapor barrier . The vapor barrier should be fixed higher than the height of the expanded clay layer. Vapor barrier film or membrane sheets are secured with a regular construction stapler or masking tape.

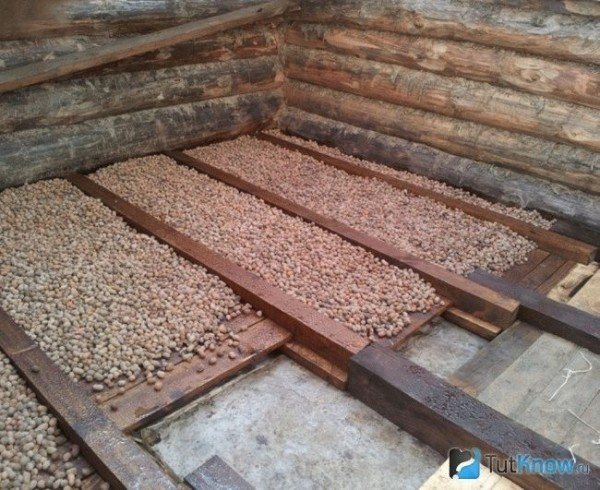

The expanded clay layer is not laid out immediately. First, lay a layer of crushed clay .

The expanded clay layer should be at least 12-15 cm. For better thermal insulation, material of two fractions is used, which are called expanded clay sand and expanded clay gravel. This will increase the density of the layer and reduce future subsidence of the granules.

Advantages and disadvantages

Insulating a bathhouse ceiling with expanded clay has many more advantages than disadvantages. Let's name the main advantages of this material :

Expanded clay has virtually no disadvantages . Except that the insulation process will be a little labor-intensive for a beginner in construction.

Insulating a bathhouse ceiling with expanded clay is popular due to the environmental friendliness, cheapness and reliability of this material. The installation technology is not very complicated and even a beginner in construction can do it.

Do-it-yourself insulation of a bathhouse ceiling with expanded clay

Insulating the ceiling of a bathhouse with expanded clay is perhaps the most important technological process, the purpose of which is to preserve heat in the room and save energy costs. Unfortunately, not everyone understands this, placing great importance on insulating the floor and walls and ignoring the ceiling, through which one-fifth of the room’s heat can be lost.

There are a number of thermal insulation materials with different properties and production methods that are used to insulate ceilings. One of the most popular is expanded clay. Let's look at the pros and cons of expanded clay.

Expanded clay is produced by firing clay rocks in rotary kilns. As a result of this firing, a porous material is obtained that retains heat well. At the same time, this material has a high degree of strength on the outside.

Thus, expanded clay is almost always a natural material. Its main advantages:

- Health safety;

- Mice and other rodents do not touch it;

- It is fireproof and does not burn;

- It weighs extremely little;

- Does not rot;

- It crumbles a lot, so when installing it, it is necessary to create a special substrate to avoid the appearance of expanded clay dust in the room.

- It is not a moisture-resistant material and quickly absorbs moisture, so it cannot be installed without the use of additional waterproofing materials.

- Be sure to use a special substrate before backfilling;

- The minimum layer of expanded clay backfill is 20 cm;

- Insulate the backfill with waterproofing;

- Do not use expanded clay for a suspended or false ceiling - it may not withstand the weight of the backfill;

- Sheets or slabs of waterproofing material must be fastened with a layer of construction tape or electrical tape;

- Be sure to level the backfill layer using a rake. If you plan to lay the floor on top, be sure to leave a small gap - otherwise the floor will creak a lot;

- At the very beginning, you need to lay a vapor barrier and underlay on the attic floor. The sheets are overlapped; under no circumstances should gaps be left. Be sure to seal all joints with construction tape, preferably foil tape. If there are beams or joists on the floor, they will also need to be covered

- Then, using the best combination of expanded clay sand and gravel, cover the entire floor surface evenly. If you are going to lay the floor on top later, leave a small gap - 2-4 cm.

- Place another layer of waterproofing material on top of the backfill. Don’t forget - expanded clay will lose up to 40% of its thermal insulation properties if it becomes wet;

- Then you have to put the floor on top. First, fill the screed, and then lay the boards or floor panels themselves.

In addition, having ordinary clay as a raw material, expanded clay is extremely inexpensive. The main disadvantages of this material are the following:

However, these disadvantages can easily be overcome by following a number of simple rules for working with expanded clay:

When talking about different types of expanded clay, we mean different sizes of its hollow granules. Expanded clay sand, gravel and crushed stone are distinguished with granule sizes of 0.1 cm, 0.2 cm and 0.2-0.4 cm, respectively.

To insulate ceilings, only gravel is used; sand and crushed stone, as a rule, have a different functionality due to their properties.

If you want to carry out such insulation of the bathhouse ceiling yourself, follow the following sequence of actions:

Despite the apparent ease of the described process, we highly recommend that you contact specialists who can do all this quickly and correctly. After all, if something was done wrong from the start, the entire floor will have to be replaced, which is very difficult.

The bathhouse is a universal place for rest, relaxation and health improvement. It is known that the bath accelerates blood flow and stagnant processes in the body, promotes the rapid elimination of toxins and waste, rejuvenates the skin, and relieves fatigue. However, the entire effect depends on how well the bathhouse is designed.

The ceiling and walls of the bathhouse must be insulated. This is especially true for the ceiling, because it is under the ceiling that the temperature is highest, and when heated, the air becomes lighter and goes into the roof, into the attic and further into the street. As a result, all the energy and all the heat heat the space around the bathhouse, and this is wasteful. If the bathhouse ceiling is poorly insulated. Condensation will appear on it. The appearance of condensation indicates that it is necessary to urgently begin the insulation process. It is best to carry out insulation at the construction stage of the bathhouse, because in this case you will not have to disassemble the structure.

Expanded clay is one of the many materials that is often used for insulation. It consists of fired porous clay granules. The unique thermal insulation properties of expanded clay are due to its cellular structure.

Due to the clay composition, the material is completely environmentally friendly and safe for health.

How to insulate a bathhouse ceiling with expanded clay? The technology for insulating the ceiling in a bathhouse with expanded clay is of medium complexity. In principle, anyone who does not have any construction skills can handle it. The insulation is installed from the attic side. First you need to put a layer of vapor barrier material. It will also perform the function of waterproofing.

The current construction market offers a huge variety of options for vapor barriers. These can be modern materials such as Izospan or analogues. You can take regular plastic film, roofing felt and aluminum foil. However, experts do not recommend roofing felt. When exposed to very high temperatures, it gets wet. In addition, roofing felt may catch fire.

If the area of the bathhouse and, accordingly, its ceiling is too large, then the vapor barrier sheets are laid with an overlap of 10-15 cm. For greater reliability, it is better to glue the seams with foil tape.

The chimney pipe and rafter beams are also laid with a vapor barrier. The vapor barrier should be fixed higher than the height of the expanded clay layer. Vapor barrier film or membrane sheets are secured with a regular construction stapler or masking tape.

The expanded clay layer is not laid out immediately. First, lay a layer of crushed clay.

The expanded clay layer should be at least 12-15 cm. For better thermal insulation, material of two fractions is used, which are called expanded clay sand and expanded clay gravel. This will increase the density of the layer and reduce future subsidence of the granules.

A regular cement-sand screed is made on top of the layer. This will protect the insulation from possible damage. Next, boards are laid on the floor of the attic, if, of course, you plan to use this part of the room.

Do-it-yourself insulation of a bathhouse ceiling with expanded clay Insulation of a bathhouse ceiling with expanded clay is perhaps the most important technological process, the purpose of which is to retain heat in

Floor insulation with expanded clay in a bathhouse

The procedure for insulating the floor with expanded clay in a bathhouse is a popular solution. This material is characterized by durability, low weight and high thermal insulation characteristics.

For the floor of the first floor and unheated rooms, a layer of expanded clay at least 10 cm thick will be required. For apartments and well-insulated houses, 4-6 cm is enough. Great attention is paid to this when laying out the project, since the height of the floor will increase.

There are several floor insulation technologies:

- standard;

- simplified;

- on the joists.

These are the most common options that provide high thermal insulation characteristics of the floor covering. They differ in labor intensity and cost. These technologies are suitable for solving various problems that require careful calculation of base and cladding materials.

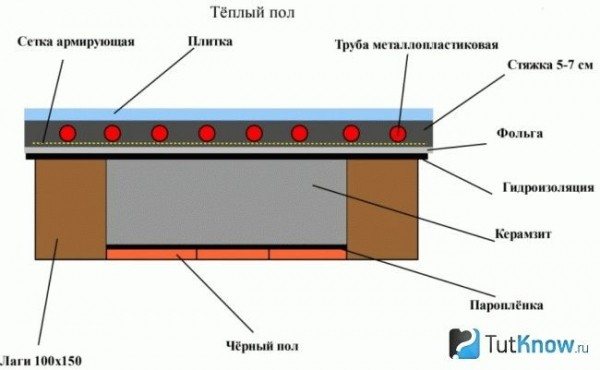

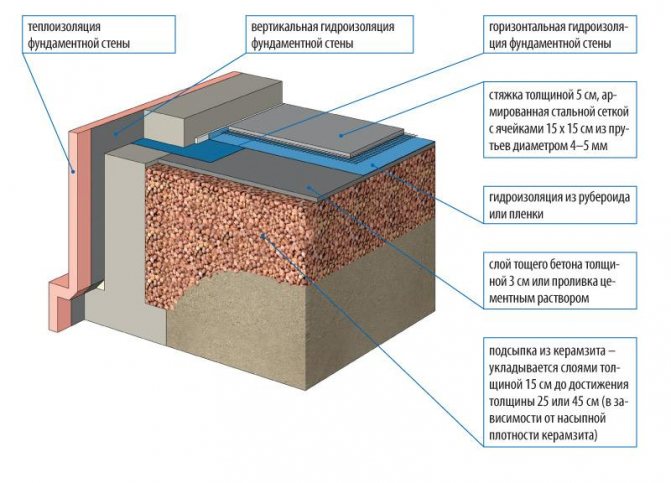

Insulating a floor with expanded clay under a screed requires a multi-stage process. When working with flooring in a bathhouse made of wood, an antiseptic composition is applied to the surface of the wood. After this, it is recommended to lay a layer of vapor barrier on the base (soil or concrete floor). To do this, you can use a special film, roofing felt and other materials with similar parameters. When working with baths, it is better to use film materials.

The next stage of floor insulation with expanded clay in a bathhouse is the installation of beacons. Using a building level, marks are applied to the walls to fix the horizontal level of the future coating. Beacons are installed in a similar way. They are necessary to level the expanded clay layer. To fix these “guides” you can use piles of concrete, asbestos, corners, as well as boards fixed with concrete mixture. You need to wait for them to harden.

It is important to achieve maximum evenness of the location of the beacons. The bathhouse requires a slight slope. It will ensure the movement of water towards the future drain hole.

The further procedure of insulating the floor with expanded clay in the bathhouse is accompanied by backfilling of granules. It is necessary to use at least 2 fractions of different sizes. Small granules will “wedge” large ones. This will prevent shrinkage and voids.

Expanded clay is poured evenly, taking into account the height of the beacons. The material is periodically compacted and distributed. There is an alternative technology, in which expanded clay is placed in bags, having previously created a hole in the fabric. The minimum layer thickness for a classic bath is higher than for most objects. It reaches 15 cm.

After insulating the floor with expanded clay, the material should be evenly distributed. For strength, it is poured with cement laitance. This procedure is carried out carefully, avoiding spreading of the granules under the influence of pressure. Impregnation provides additional protection from moisture (the mixture fills all voids on the surface of the grains). When using an alternative technology with packing in bags, filling with milk is ineffective.

At the last stage of insulating the floor with expanded clay, the screed is poured. Using GVL for a bathhouse is not suitable, so it is better to use a layer of concrete or self-leveling polymer floor.

To prevent subsidence and strengthen the structure, a reinforcing mesh is laid on the expanded clay. For optimal results, 3-4 cm of screed on top of the insulation is enough. Using the wet method takes time to harden.

You can use the floor after 2 weeks, but it is better to wait at least a month. During this time, the cement will become strong. A test with a glass jar (it should not fog up when placed upside down on a concrete floor) will help to accurately determine the readiness of the screed.

After this, a decorative coating made of moisture-resistant materials is applied.

How to insulate the ceiling in a bathhouse with expanded clay

The ceiling in the bathhouse should hold heat well. You can avoid heat loss from the attic by insulating it with expanded clay. It has been used as insulation for a long time, but has not lost its popularity.

Expanded clay is a bulk building material made from clay by firing in special rotary kilns.

It is used not only as insulation, but also as a filler in the manufacture of lightweight concrete.

Thermal insulation qualities are due to its porous structure, which creates the effect of a thermos. Expanded clay is produced in different fractions: from sand (1.5–5 mm) to crushed stone 40 mm. The most popular granule size is 10–20 mm. This is what is most often used when insulating the ceiling.

Expanded clay has a number of positive properties:

- Resistant to cold. Withstands up to 25 cycles of freezing and complete defrosting.

- Not flammable.

- Biologically inactive.

- Easy to use.

- Light weight (1 m³ = 250 kg).

- Low thermal conductivity – 0.12–0.15 W/m².

- Low cost.

At the same time, it also has negative qualities:

Carrying out work

Insulating the ceiling does not mean just pouring a layer of expanded clay. There are a number of nuances in this task that must be taken into account to obtain the desired result.

It should be remembered that insulation with expanded clay makes the structure heavier. Therefore, you will need to take care of the reliable fastening of the ceiling boards and, if necessary, strengthen them.

Before starting work, you need to prepare moisture and vapor barrier materials. The following options are valid:

Insulating a bathhouse begins with laying moisture-proofing materials. The simplest option is to apply clay coating to the ceiling boards. The thickness of such a vapor barrier should be 1.5–2 cm. The use of this insulation requires great physical effort and time. The coating takes at least 3 weeks to dry. Therefore, crumpled clay is used for the same purposes. Waterproofing is laid on the coating layer, the role of which is polyethylene film or roofing felt. The width of the material should be 10–15 cm greater than the distance between the floor beams. If the moisture barrier is laid overlapping, then the seams are glued with bitumen mastic or tape.

Expanded clay is poured between the beams, directly onto the prepared insulating material. Heat-saving properties are fully ensured when the insulation thickness is more than 10 cm. The recommended value is 14–16 cm. Expanded clay is poured into an even layer and leveled. For compaction purposes, material fractions of different sizes are used. Special attention is paid to the completeness of the backfill around the rafters, chimney and walls. The quality of laying the material directly affects heat loss. To prevent convection currents from occurring in the expanded clay layer, it is recommended to fill the insulating material with ordinary dry sand on top, having previously covered the expanded clay layer with agrofibre. It prevents sand from spilling out and does not create a “greenhouse effect.” Layer thickness – 3–5 cm.

Work on insulating the ceiling of a wooden house is almost no different from the technology described above. There is no need to install a vapor barrier here. Only waterproofing is used. If the house is two-story, then lighter materials are used for the ceiling of the first floor or it is not insulated at all.

Checking completed work

After this, you need to ensure the quality of the insulation made. To do this, the bathhouse is heated and all sources of cold air (doors, ventilation, etc.) are closed. After warming up the room, the temperature is measured and the time is recorded. If it decreases quickly, then the insulation work was performed poorly. Then the reasons for the temperature drop are identified and eliminated. After this, the check is repeated. In a good sauna, the heat lasts up to 4 hours.

Periodically it is necessary to inspect the attic space for damage to the roof covering and moisture leaks. Such inspections are also necessary during heavy precipitation.

The ingress of water into the expanded clay layer significantly reduces its heat-saving qualities. Therefore, all leaks must be eliminated.

Insulating the ceiling alone will not solve the problems of maintaining heat in the room. Expanded clay is an almost ideal heat insulator, but only the integrated use of energy-saving technologies and materials will make your creation a truly Russian bathhouse.

Insulating the ceiling with expanded clay is one way to avoid heat leaks from the attic.

Bathroom insulation with expanded clay

To maintain a stable temperature in the bathhouse and minimize heat loss, special attention must be paid to the thermal insulation of the structure. It is important to take care not only of insulating the walls, but also the floor and ceiling. For these purposes, various synthetic and natural materials are used. Of the latter, expanded clay is the most popular.

Types of expanded clay

Expanded clay is represented by round granules with a porous structure made of baked clay.

. Available in grain sizes from 0.1 to 10 mm. It is used as a filler in mortars and as a backfill when insulating bathhouse ceilings up to 50 mm thick. Price - from 150 rubles per bag.

Features of bathhouse thermal insulation with expanded clay

Expanded clay is a natural material, which means it is environmentally friendly. However, environmental friendliness is not the only advantage of this heat insulator. It is very popular when insulating a bath due to its many advantages, such as:

- Cheap

. Compared to most synthetic insulation materials, expanded clay has a low cost.

As for the disadvantages of using the material, among them we can highlight the labor-intensive process of thermal insulation. In addition, when using expanded clay to insulate a bathhouse, it is necessary to pay special attention to vapor and waterproofing.

Bathhouse insulation technology with expanded clay

Instructions for insulating a bathhouse ceiling with expanded clay

When calculating the amount of material for thermal insulation of the ceiling in the bathhouse, keep in mind that the layer should be 20 cm or more. Insulation is carried out from the attic side. If desired, you can mix expanded clay in the form of sand and gravel. This will make the backfill as dense as possible.

Features of floor insulation in a bathhouse with expanded clay

The thermal insulation of the flooring in the steam room must be taken care of at the stage of its construction or major repairs. It is also important to take into account the maximum permissible load when calculating the layer thickness.

- We spread the waterproofing bitumen material on the concrete covering with an overlap of 10 cm. The overlap on the walls should be about 15 cm.

If you decide to insulate with expanded clay over the ground in a bathhouse, then its layer will be significantly thicker (about 30-35 cm), which will raise the height of the floor. This must be taken into account at the stage of designing the height of the walls of the bathhouse.

Specifics of insulating bath walls with expanded clay

Bulk materials can only be used for thermal insulation of brick walls of buildings. This process must be thought through during construction.

Effective thermal insulation of a bathhouse with expanded clay can be done with your own hands, if you take into account all the nuances of this process. The material is hygroscopic, and therefore the insulation of surfaces must also be carried out reliably. By adhering to general recommendations and instructions, you can easily insulate a steam room with an environmentally friendly and durable heat insulator.

Environmental friendliness, durability and low cost are the main advantages of expanded clay, which allow it to be used for insulating steam rooms. However, due to the hygroscopicity of the material, during the thermal insulation process it is necessary

Organization of floor insulation in a bathhouse with expanded clay

The main task that becomes paramount when carrying out work on the construction and arrangement of a steam room is the maximum reduction of heat loss from the room. Otherwise, certain difficulties may arise in heating the room to the desired temperature, since it will cool down faster than required. This will entail an increase in heating costs. The pleasure of spending time in such a steam room becomes rather doubtful. It is better to think about solving the issue of insulation at the stage of building a bathhouse. This approach will be logical and competent.

Expert opinion

Konstantin Alexandrovich

There is an opinion that the procedure of floor insulation is not mandatory, it is only an extra expenditure of effort and money. This point of view is fundamentally wrong. An uninsulated floor can in many cases become a source of significant heat loss. Even if the ceiling and walls are thoroughly insulated. In fact, a high-quality insulated floor can extend the life of a bathhouse and increase the degree of comfort in it.

In the old days, bathhouse floor insulation was done using natural materials such as hemp, flax, jute and even moss. It is easy to notice that these days the choice of highly effective insulation materials produced using the most advanced techniques is very large. And the use of materials such as moss can be a catalyst for the development of mold and fungal infections of wood.

How to insulate a ceiling with expanded clay

The issue of a structure’s ability to accumulate heat always remains relevant for owners of their own homes. The amount of heating costs and living comfort directly depends on it. That is why it is difficult to do without high-quality insulation.

As a rule, everyone tries to insulate the walls, forgetting about other parts of the structure, but this cannot be done. Up to 15% of the heat passes through the ceiling alone. Many people in this matter resort to using foam boards for insulation, but there are excellent alternative options. Next, let's look at why attics are often insulated with expanded clay and what are the features of using this material.

Advantages and disadvantages

List of positive features when using expanded clay as ceiling insulation:

Expanded clay also has low sound and thermal conductivity, but the material also has some disadvantages:

Having considered the positive aspects of the material, the negative ones seem completely insignificant.

Features of insulation with expanded clay

Before carrying out the insulation process in a private house, it is necessary to conduct a detailed analysis of the entire structure: walls, floors and ceilings. Only if there is a complete understanding of the characteristics of the thermal resistance of all materials from which the construction of a house, bathhouse or other structure is made, it is possible to achieve high thermal efficiency of the building using insulation materials.

Insulation of the ceiling of a bathhouse or in a private house is considered effective if its thickness is in the range of 20–40 cm.

Also, when choosing expanded clay as a ceiling insulation, you need to take into account some features of its use:

When insulating a bathhouse made of wood or frame slabs, expanded clay must be completely protected from moisture. To do this, waterproofing material is laid on both sides (bottom and top).