What are the structural elements of the bathhouse determines the structure of the erected structure by its purpose. And it must be said that the structure of the bathhouse you build yourself will be individual in the case when all these elements are original.

But at the same time, they are always present, regardless of what materials the bathhouse was built from, and what the price of these materials is.

>

Photo of a classic bathhouse with all its structural elements

Insulation of walls in a frame bath

When building the walls of a frame bathhouse with your own hands, you should seriously think about how exactly you will insulate it. The fact is that each of the layers described above plays its own special role in the process of heat conservation, so there are nuances in the installation of each of them, which must be taken into account when carrying out finishing and construction work.

For example, frame walls, as well as insulation and vapor barrier of a bathhouse can be carried out in two different ways: inside and outside. The best option is a combination of these two methods, since in this case the wall will be protected both from the inside and from the outside. In the same case, when you live in a relatively warm area, it will be more complete to insulate your building from the inside.

From a technical point of view, installing insulation is not particularly difficult, since almost all types of modern heat insulators are produced ready-made, and all you have to do is install them in place using the instructions included with the insulation kit. If you use ancient insulation methods, for example, using shavings or slag, you will have to separately clarify how to insulate the walls in a frame bathhouse using them.

In addition, it is worth learning separately how to build the floor and walls of a frame bathhouse. The fact is that it is best to insulate the same floor during the construction of the building, rather than opening it up to carry out additional work on installing thermal insulation. Usually the floor is insulated with the same materials as the entire building, for example, mineral wool, but expanded clay can also be used for this, pouring it under the floor boards into the space between the joists.

Separately, it is worth mentioning this type of bath insulation as a warm floor. It is carried out by installing heating elements running on electricity, or using the energy given off by hot water. In this case, you will have to use a separate technology to equip the floor in your bathhouse, but as a result you will be able to regulate the heat level of your floor, and also provide the building with additional heating capabilities.

Before installing insulation in a frame bath, experienced builders recommend installing electrical wiring and other utilities.

The fact is that it is not recommended to open frame walls several times, as this negatively affects their durability. It will be optimal when you perform all the necessary operations just once, while hiding all the wires and pipelines in a non-flammable and moisture-proof box.

Structural elements of the bath

Foundation

Columnar foundation design

First of all, it refers to the load-bearing part of the entire bathhouse. Due to its location in the ground, it is exposed to moisture and can freeze, and therefore must be strong and resistant.

This means that when creating it, strict adherence to technology and the use of good quality materials is necessary.

- How deep the foundation is laid is determined by the type of soil. In clayey and loamy soils that swell when frozen, the foundation base is laid 20 cm lower than the freezing level. If the soils are sandy or gravelly, then the depth of the foundation depends on the freezing level. In this case, it is necessary to take into account the level of groundwater, but not less than 0.5 meters from the surface.

- According to their design, bathhouse foundations are divided into columnar and strip.

- To protect the foundation from rain and surface moisture, a blind area is required.

Wall construction

The best baths are those whose walls are made of logs or timber. These materials retain heat well and are capable of permeating air and water. Thanks to this, natural air exchange is observed in such baths, a pleasant smell and a comfortable atmosphere are preserved.

When constructing such walls, coniferous wood is used, and harvesting should take place in winter, with minimal sap flow. Well, the simplest and most convenient material for the construction of buildings is considered to be timber.

Timber for bath walls is the best material

Advice: It is best to build bathhouses from timber or logs in winter; in this case, when drying, the material already in the log house cracks less and is less prone to distortion, that is, it twists less.

When building bathhouse walls, lightweight bricks or stones with voids can be used. But in this case, additional insulation is necessary, but there are other advantages: durability and less fire hazard.

Walls made of gas silicate or foam concrete blocks retain heat well. But for such walls, both external and internal finishing is required, due to the high hygroscopicity of these materials.

Roof structure

The main characteristics of the roof should be strength, lightness and water resistance. There are flat, single- and gable roofs. For a bathhouse, gable roofs are more typical; in some cases, hips are added for beauty.

Advice: If constant strong winds prevail in your area, then you should make the roof as flat as possible, in case of large amounts of precipitation: snow in winter and rain in summer, make the slope steeper.

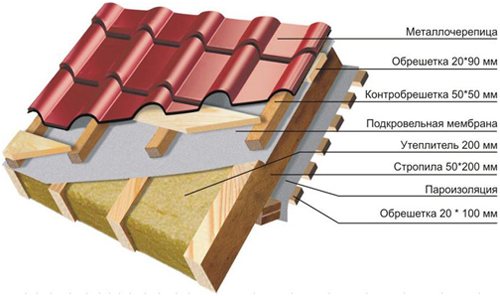

Structurally, the roof consists of rafters, a load-bearing part, moisture insulation, a thermal insulation layer, counter battens, sheathing and roofing material. Quite often, in the absence of an attic and if the attic space is well ventilated, waterproofing and insulation are not used.

Complete roof structure for metal tiles

The type of sheathing is determined by the type of roofing material. If you plan to use slate, metal tiles, ondulin or profiled sheets, then boards 25 mm thick, mounted at a certain distance from each other, are enough to arrange the sheathing. If natural tiles are used, then bars 50 mm thick are needed, and the distance between them is determined by the size of the material.

When installing a soft roof, the sheathing is made double, where edged boards with a thickness of 25 mm are nailed down as the first layer, and plywood with a thickness of 5 mm or more is laid in the second layer. Soft roofing material is laid on top.

Floor design

The design of the floor in the bathhouse is the initial stage of interior decoration. Before laying the floor, it is necessary to construct a drainage system and prepare the foundation for the stove. Only if the instructions for arranging drainage are followed, there will be no musty smell in the bathhouse and excess water will be drained away.

Attention: For optimal drainage, the floor in the steam room and washing room should be located at a slight slope.

Most often, the floor in the bathhouse is made of wood, and according to its design, it can be leaky or non-leaky.

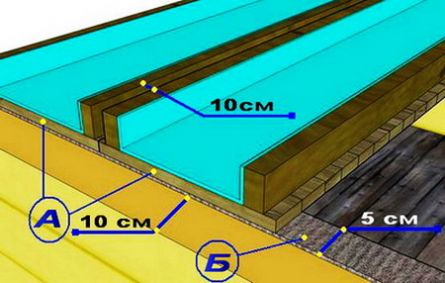

When laying boards on logs that rest on the foundation, as well as posts in the middle, and the boards are mounted solidly, a leak-proof floor is obtained. At the same time, subfloors are installed, and the space under the finished floor is insulated. The floor surface has a slope in one direction or towards the center of the room.

Installation of non-leaking floor

To repair a leaking floor, it is necessary that the soil absorbs water well, or appropriate measures must be taken. A layer of soil is removed, up to about half a meter, and crushed stone or expanded clay is poured.

Fill with concrete, and the surface of the concrete should have a slope towards the water receiver. After that, carefully polished boards are laid on the logs, leaving gaps of about 1-2 cm between them.

This is what a leaky bathhouse floor looks like

No tilting is required in the waiting room and rest room. Therefore, it is laid with tongue-and-groove floorboards, with subfloors and insulation underneath. Non-slip tiles can also be laid.

Ceiling design

Structurally, the bathhouse ceiling consists of beams, suspended ceiling boards, rolled sheathing, insulation and vapor barrier.

There are suspended, floor and panel ceilings.

- False ceiling.

When erecting the walls of the bathhouse, ceiling beams are laid. During the finishing process from below, they are sheathed with some finishing material, most often clapboard.

A layer of vapor barrier is laid on top of the lining, then a layer of insulation, and again a vapor barrier. It is possible to cover the top with some kind of boards, or unedged ones.

Installation of false ceiling

- Flat ceiling.

Most often, such a ceiling is made in small, 2-3 meters wide, rooms. The finishing material is laid directly on the top frame of walls and partitions. A vapor barrier is spread over this material, then insulation, and again a vapor barrier.

Attention: To prevent the insulation from falling out at the edges, special protective edges are constructed around the perimeter of the room.

Expanded clay on top of a floor ceiling

- Panel ceiling.

Special shields are assembled in advance, with a width of one meter and a length equal to the length of the room. A box made of boards, covered both at the top and bottom. Inside is a sandwich of two layers of vapor barrier and insulation. Then the ceiling is assembled from such panels.

Advice: since the assembled shields are quite heavy, it is worth assembling them directly at the top

.

Installation of a panel ceiling at the top

Choosing insulation for frame walls

The effectiveness of insulation of frame buildings directly depends on the choice of the type of insulation material. Moreover, any heat insulator in a bathhouse must be able to withstand high temperatures and significant levels of humidity. It is also imperative to pay attention to the fact that the material used as insulation does not release toxic substances when heated. It is especially important to comply with the listed conditions when selecting material for the internal insulation of a bathhouse, since it is this material that will come into contact with the human body during the process of bathing procedures for you and your guests.

Modern insulation materials can be natural or artificial. Artificial ones are most common due to their high technical characteristics and low cost. Natural, environmentally friendly ones can be used in the process of insulating a traditional Russian bath or Finnish sauna.

As for specific types of insulation, the following are presented on the construction market:

- Mineral wool boards. They are made from fine fibers formed from molten rocks or the metallurgical industry. The air voids formed during the weaving of fibers during the formation of this material perfectly retain heat, which gives such slabs excellent thermal insulation properties. In addition, they do not burn and do not emit toxic substances when heated, and are also not afraid of high humidity.

- Reed slabs. This type of insulation is absolutely environmentally friendly and also has excellent heat-insulating qualities. Its thickness is 15 cm, which is simply ideal for the construction of frame walls. It is installed in a manner similar to the installation of mineral wool insulation, so you can use it to insulate your bathhouse yourself. However, this material burns, so it is necessary to pay special attention to its anti-feather impregnation.

- Gypsum-sawdust mixture. This type of insulation is good because you can very easily make it yourself; all you need to do is mix 10 parts of well-dried sawdust with 1 part of cement or gypsum. As a result, you will end up with good thermal insulation material at a very low price.

- Polymer-based materials. These are polystyrene foam, polyurethane foam and the like. They have the following advantages: low cost, ease of installation and processing, light weight, excellent thermal insulation qualities and absolute immunity to moisture. However, they burn well, are sensitive to high temperatures, and can emit unpleasant odors during the heating process. In connection with this, they are recommended to be used only in places where there are no high temperatures, namely in the dressing room, sink, rest room.

The choice of a specific type of insulation material directly depends on several factors, the main one of which is the climate in the area where you are going to build a frame bathhouse. In addition, it is also worth considering the type of heating you are going to use. For example, gas heating allows you to regulate the level of heating of the air in the bathhouse quite subtly; therefore, synthetic insulation materials can be used to insulate most rooms in the bathhouse. A wood-burning heater usually gets hot during operation, so it is better not to use materials that are unstable to high temperatures near it.

In the same case, when you cannot independently choose insulation for your bathhouse, you should seek advice on this from an experienced specialist. He will help you choose the necessary material, and also tell you some of the subtleties of installing it on a frame wall.