Bathrooms, be it a washing room or a steam room, are characterized by a high amount of moisture.

However, most baths are made of wood, a material prone to rotting.

How to insulate the ceiling in a bathhouse so that you don’t have to change it in the near future, and your stay in the steam room is comfortable.

What material is best to choose for insulation and what is the insulation process?

First, briefly about what ceiling insulation provides

- Economical operation . Fast heating, due to reduced heat loss through the roof, allows you to reduce energy consumption (wood, coal, electricity, gas, etc.);

- Comfort for steamers . The absence of condensation that “pleasantly cools” people’s backs and the musty smell resulting from dampness;

- Durability of the structure . Prevents excess moisture, preventing the creation of a convenient bacteriological environment for the appearance of fungus, mold and wood rot.

Enough arguments? Then let's get down to business, and please pay attention to the next paragraph...

“When you have a bathhouse, just a bathhouse, you come, heat it, take a steam bath and leave, there is no need to insulate the roof. But if the attic or attic is used for storing clean linen, as a rest room, drying brooms and other household chores, then major insulation is necessary. Please note that we were talking about the roof. The ceiling must be insulated in any case. Many people confuse roof insulation with ceiling insulation.”

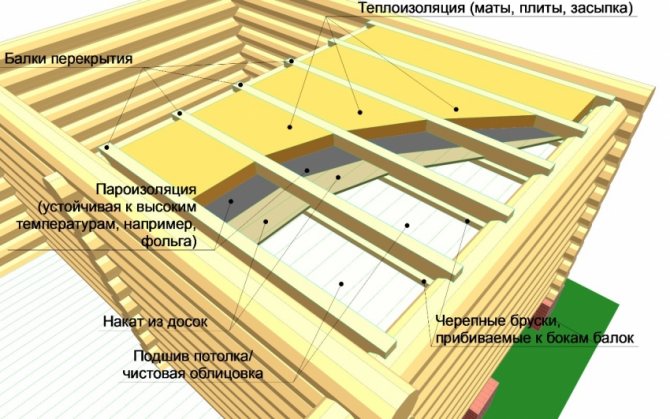

What types of ceilings are there in a bathhouse? Here are the main types - hemmed / floor / panel. Each option has its own design features. But the insulation process is almost the same. We will not consider this, since we have a different topic now.

So, materials. There are two main types of insulation for baths, which we roughly divide into natural (“old-fashioned”) and artificial (including those made on a natural basis with the addition of artificial substances).

Mineral wool installation methods

The counter-lattice is placed over the vapor barrier on all working surfaces.

We will consider baths with beam ceilings, since this is the most common design. It's rare to find a sauna with concrete ceilings. Let's divide the installation into two groups:

- walls;

- horizontal ceilings (ceiling and floor).

As we have already said, mineral wool for a sauna can be laid on the walls from the outside and from the inside. We have already looked at methods for external insulation of a house, so we will focus on internal work. Moreover, it is cheaper. To begin with, we select the cross-section of the bars for the future sheathing. The height of the beam should be such that the mineral wool lies flush, or even more. The pitch between the guides is three centimeters less than the width of the insulation. The bars are attached perpendicular to the floor.

Mineral wool is placed between the guides. Penofol is stapled on top of the sheathing with the foil inside. Vapor barrier tapes should not overlap; they are placed end to end. The joints must be glued with aluminum-coated tape to create a monolithic mirror. A horizontal counter-lattice is placed on top of the vapor barrier, which is then covered with clapboard.

Penofol on the walls, floor and ceiling must be combined to form a sealed protective layer, like in a thermos.

Insulating the ceiling in a bathhouse with mineral wool and the floor can be combined, since the technique is almost the same. In both cases, the insulation is placed on the rough covering:

- on the subfloor from the inside;

- on the rough ceiling - from the outside from the attic.

There are no tricks here, you just need to lay the required layer of mineral wool flat. Next comes the vapor barrier, which is always placed between the insulation and the heated room. Penofol is placed on the floor on top of mineral wool, the joints are sealed and a counter-lattice is filled for a final finish. With the ceiling, things are different, since not only the thermal insulation, but also the load-bearing beams need to be protected from moisture. Therefore, penofol is attached to the rough ceiling from the inside with the shiny side facing the middle of the room. All this is sealed and a counter-lattice is filled for further finishing.

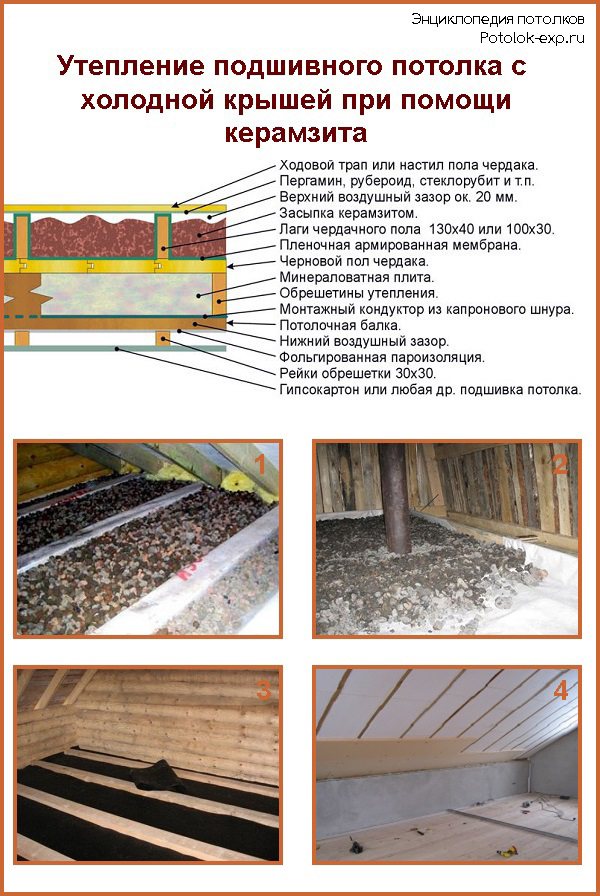

Insulation of the ceiling in a bathhouse with a cold roof, depending on the characteristics of the roof

The roof of a bathhouse can be represented by one of two types: with an attic space and without it. In the first case, the air layer itself creates a fairly effective barrier, which has a positive effect on the building’s ability to retain heat. But this does not mean that the presence of an attic completely eliminates the need for insulation work.

If the bathhouse does not have an attic or attic, then high-quality thermal insulation is an almost mandatory condition for the further use of the building for its intended purpose.

Regardless of what type of room you are faced with, the first and extremely important step is to provide a vapor barrier layer. Available materials such as aluminum foil, high-density cardboard, which is pre-impregnated with drying oil, or wax paper are perfect for this.

Before laying the thermal insulation layer, you should take care of the reliable vapor barrier of the bathhouse roof

Helpful advice! If work is being done to insulate the ceiling in a bathhouse where there is an attic space, then it is recommended to coat the ceiling boards on the roof side with a layer of clay about 2-3 cm.

Principles of thermal insulation

To obtain a high-quality result when insulating the ceiling in a bathhouse, you should pay attention to the roof structure, which is usually made in two versions: with and without an attic ceiling .

If insulation work will be carried out on the attic ceiling, then the elimination of cracks with an insulator should be carried out during the construction stage. Due to the presence of a fairly powerful ceiling structure, air flows will be securely locked inside the room. And although the ceiling, which includes an attic, is quite thick, insulation in this case must be carried out without fail. The same applies to buildings that do not have an attic, where it is usually easier for air to find its way out in the ceiling.

Nuances of insulating the ceiling in a two-tier bathhouse

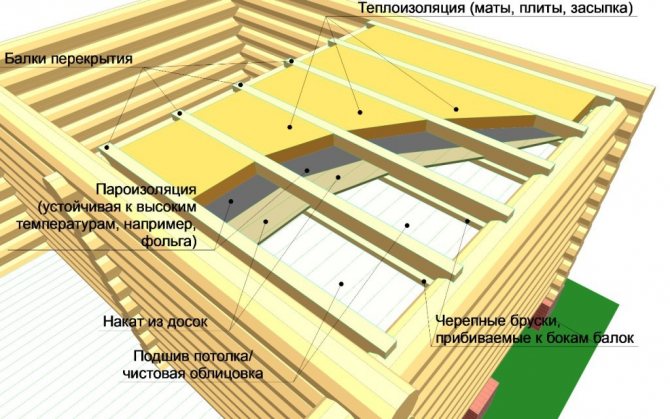

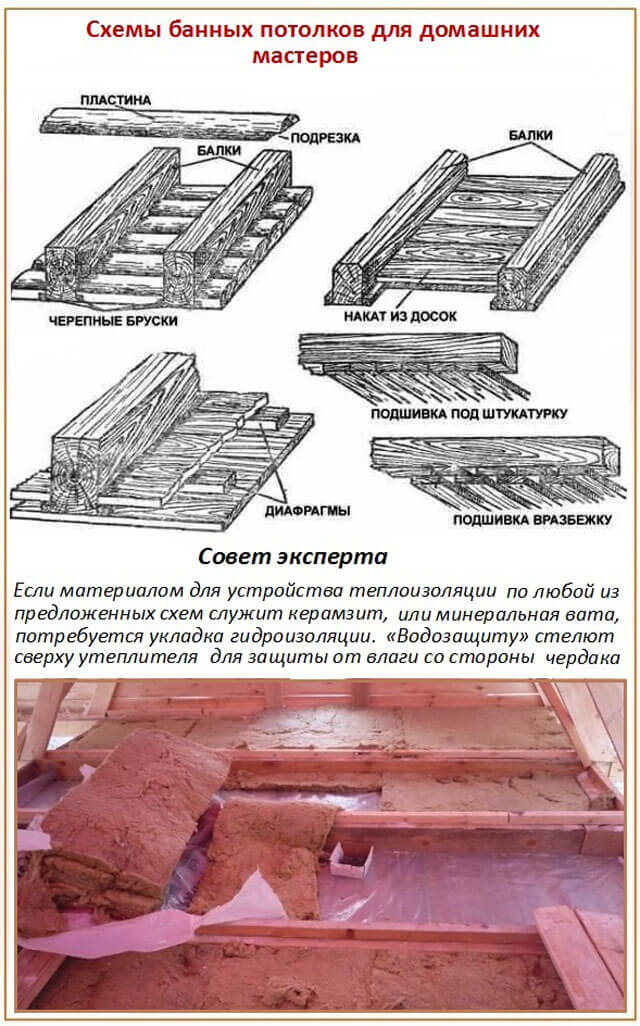

Bathroom ceiling insulation scheme

In accordance with the design features of the structure, baths can be divided into 2 large groups: those with an attic/attic floor and those without one. The standard scheme for insulating the ceiling in a bathhouse without an upper tier was presented above. The procedure for thermal insulation of the ceiling in a bathhouse with more than 1 floor deserves separate consideration.

The technology for constructing a bathhouse with an attic floor involves installing a ceiling structure that is much more powerful in its performance. An additional obstacle to the flowing warm air masses will be the space under the roof itself, as well as, to some extent, the roof structure itself.

In bathhouses that do not have an attic/attic tier, warm air masses encounter much fewer obstacles, and their strength is also noticeably lower. Despite this, ceiling structures both in bathhouses with an upper tier and in buildings without one need high-quality and competent insulation.

Examples of proper ceiling insulation in a bathhouse with an attic/attic are shown in the following image.

Examples of proper ceiling insulation in a bathhouse with an attic/attic

Important note! If the ceiling is made of logs, a sheathing is installed on the side of the bathhouse, the logs are covered with a vapor barrier, a 20-centimeter layer of sand is poured on top and then insulation is carried out according to the standard scheme. Skull boards can be mounted on top of logs.

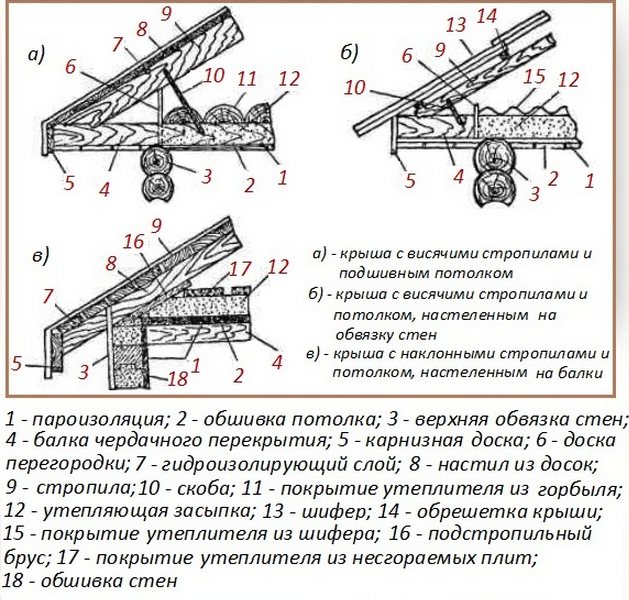

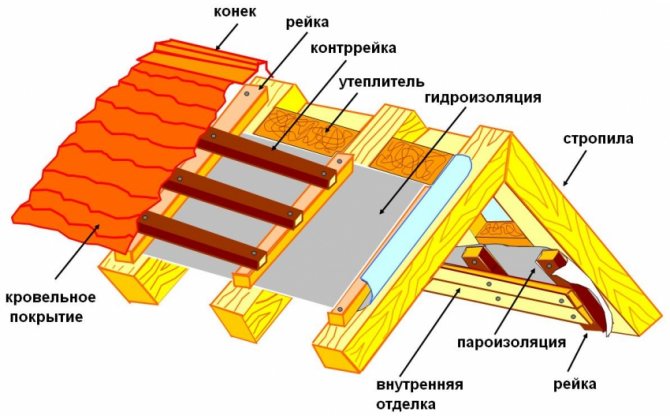

The design of the ceiling and roof of a bathhouse without an attic is as follows.

The design of the floor and roof of a bathhouse without an attic The structure of the floor and roof of a bathhouse without an attic

General scheme for insulating ceilings in baths and saunas

Up to a third of the heat from the red-hot arches of the chimney stove is transmitted through heat rays. Therefore, just like the walls, the ceiling of the steam room is covered with a reflective screen. The best material for this is aluminum foil and flexible roll sandwiches containing it as the base layer. From the side of the room, the reflector is covered with a decorative panel made of wooden paneling.

Bathroom ceiling insulation scheme

Being the “front line of defense”, foil materials perform several functions at once, in addition to reflective: they provide vapor barrier to the insulated ceiling in the bathhouse and eliminate gaps for convection heat loss. In order to maintain the air gap, the main insulation is located behind the reflective screen, which, unlike the wall equipment, is necessary for the ceiling of the bathhouse, regardless of the design of the roof and the under-roof space.

In general, the sandwich diagram for insulating the ceiling in a bathhouse looks like this, if you list the layers from bottom to top:

- foil reflective screen with its own insulating layer;

- air gap;

- main insulation;

- waterproofing layer;

Between the infrared screen and the main insulation of the steam room ceiling, depending on the type of ceiling, there may be a boardwalk (1) or a concrete slab. In accordance with this, thermal insulation is considered external or internal. In particular, insulation of the ceiling in a bathhouse with a cold roof and concrete ceiling is carried out exclusively from the inside.

Artificial insulation

Artificial - mineral wool of various types, ecowool, sprayed insulation. Their advantage : excellent thermal insulation, fire resistance, moisture resistance and durability. Disadvantages : complete or partial “unnaturalness” and price.

The list of artificial insulation materials does not include polystyrene foam, penoplex and some others. But they are not considered the best for a bath. Why? They belong to the so-called “non-breathable insulation”, and in the bathhouse, as you know, it is always humid. This moisture will have a bad effect on wooden structures. I also do not recommend using “poured” foam concrete, which carries loads and does not tolerate humidity and temperature changes.

Mineral wool “effectively, quickly and honestly returns every ruble invested.” It is divided into glass, stone and slag. They differ in the thickness and length of the fibers, load resistance, hygroscopicity, fire resistance and thermal conductivity. We will exclude glass wool for the reason stated above. Let's look at the rest in more detail.

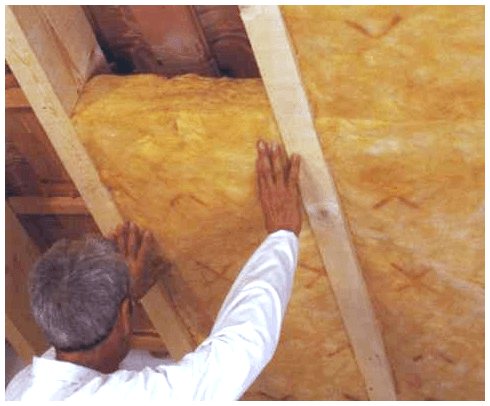

Ceiling insulation with mineral wool

Slag wool: The starting raw material is blast furnace slag.

Advantages:

- — good thermal conductivity;

- — ability to withstand temperatures up to 300°C;

- - light weight;

- — excellent sound insulation qualities;

- - not friendly with mold and fungal spores

- — the price is 2-4 times lower than that of basalt insulation (stone wool);

“And mineral wool is the most convenient insulation when arranging attics with irregular geometry and uneven surfaces.”

Minor cons:

- - tendency to shrink;

- — high hygroscopicity (ability to absorb moisture);

- — brittle and prickly fibers of long length (gloves, a respirator and special clothing are required when laying).

Stone (basalt ) wool: The initial raw material is melted rocks based on basalt.

Advantages:

- — perfectly accumulates heat;

- — ability to withstand high temperatures (up to 1000°C);

- — the dense structure of the fibers ensures resistance to shrinkage (in comparison with “soft” slag);

- - low hygroscopicity (again in comparison with slag wool);

- - not to the taste of rodents;

- - not friendly with mold and fungal spores;

- — short and thick fibers, do not require a respirator when working;

- - longer service life (compared to slag).

Flaws:

- - high price;

- - more expensive transportation;

- - low elasticity, which does not allow effective insulation of uneven surfaces.

Ecowool insulation

Ecowool for insulating a bath ceiling would be an excellent option. It does not rot, retains heat well, and perfectly “regulates” temperature and humidity conditions, which is very important for working in “harsh” conditions. Rodents do not like it, it is absolutely fireproof and affordable.

Perhaps there is one drawback - not everyone knows how to work with it. And not many people know what it is. For those who are interested in this material, welcome here.

Sprayed insulation - it can be called a new product on the construction market. This is something similar to polyurethane foam, for example, Polinor. True, a significant number of such cylinders will be needed to insulate the ceiling, but for small areas, it will do just fine. For larger volumes, there are industrial installations for spraying polyurethane foam. Here is a video showing this method, and here is an article with a full description of the entire insulation technology...

Do-it-yourself insulation of a bathhouse ceiling: advantages and disadvantages of mineral wool

Mineral wool is by far the most popular option among all. It is often used for insulation not only of bathhouses and garages, but also for residential buildings. In itself, it is a fibrous material that has excellent thermal insulation characteristics and can be presented in one of three types:

- glass wool;

- stone wool;

- slag wool.

But if the first option is familiar to almost everyone, then not everyone has seen the other two. Rock wool is a material made primarily from basalt, although it is sometimes made from other rock melts. Slag wool is very similar to cinder blocks, for the production of which blast furnace slag is used.

Mineral wool is characterized by significant resistance to high temperatures and also has excellent heat and sound insulation properties

In addition to the fact that mineral wool has low thermal conductivity, which allows it to be used for thermal insulation of ceilings and walls, it has another significant advantage. Unlike other materials, it cannot serve as a breeding ground for microorganisms: fungi, mold, small insects or rodents, which is very useful for summer cottages.

As for other characteristics, mineral wool is not prone to fire and does not react in any way to temperature changes: it does not deform or shrink. Light weight and convenient packaging (usually in the form of rolls or rectangular slabs) make it easy and convenient to work with the material, even alone.

Of course, this material also has disadvantages that one way or another will have to be taken into account:

- mineral wool can absorb moisture;

- it contains phenols, which can potentially pose a hazard to human health.

Insulation with mineral wool is necessarily accompanied by additional waterproofing of the surface

Both of these disadvantages can be neutralized during the installation process, providing the insulation with high-quality vapor and waterproofing, completely eliminating the risk of contact of mineral wool with air under the ceiling. This is especially true for warm and humid air, which is concentrated indoors.

Helpful advice! Despite the fact that, if all installation rules are followed, mineral wool does not pose a real threat to health, during its installation it is necessary to be careful and use protective equipment, since its small fibers can cause irritation to the skin and eyes.

Insulation of the ceiling in a bathhouse with expanded clay: features of use

Expanded clay is small-sized pebbles that consist of clay and have a porous structure. If we take into account all the factors, then expanded clay can be called the most suitable material for insulating the ceiling in a bathhouse. Of course, if the building has attic space and there is a possibility of using it.

Distinctive features of expanded clay as an insulation material are the high hydrophobicity of the material, as well as resistance to the development of microorganisms and fungi

The advantages of this choice can confidently include the following aspects:

- expanded clay is completely safe: it does not support combustion, is environmentally friendly and even in the event of a fire will not release hazardous substances into the atmosphere;

- over time, as well as under the influence of external factors, expanded clay does not deteriorate and does not decompose;

- the cost of the material is quite low;

- bacteria and fungi do not consider expanded clay an attractive environment for life.

In addition, expanded clay is superior to mineral wool in its ability to not absorb moisture. And although the need to equip steam and waterproofing layers remains, the risk of moisture accumulation inside the insulation layer is much less. It should also be noted that the service life of expanded clay is one of the longest when compared with other materials.

Expanded clay can be used to insulate both ceilings and floors

Is it worth it to insulate the ceiling from the inside with polystyrene foam?

At a certain period, foam plastic was the leader among thermal insulation materials, which were used to insulate not only bathhouses, but also residential buildings. But with the advent of alternative options, its significant shortcomings became noticeable. So, for example, in the event of a fire, polystyrene foam burns well, while also emitting toxic smoke that can harm human health.

In addition, polystyrene foam is not very resistant to external factors, collapsing under the influence of high temperatures, which is inevitable if it is used in a bathhouse.

For these reasons, we can conclude that polystyrene foam is far from the most suitable material for this purpose and it is better to give preference to another material that is more stable and suitable for its characteristics.

Many builders prefer to insulate the ceiling of bathhouses with penoplex foam with a thermal layer rather than polystyrene foam

Using ecowool as insulation for a bath

Another material that is popular among insulation materials and is often used for bathhouses and garages is ecowool. This fibrous material is made from cellulose, adding special impurities to it to provide protection against insects, bacteria and rodents. In addition, they make ecowool resistant to fire.

The advantages of this material include environmental friendliness, as well as low weight and the ability to fill even the smallest cracks and gaps, which is very convenient when it comes to working with a not too smooth surface. It does not emit any toxic substances so, like expanded clay, it is completely safe for human health.

But there is also a significant drawback: the effectiveness of using ecowool is directly related to the presence of ventilation, as well as a high-quality waterproofing layer, which is designed to remove moisture. This is due to the fact that ecowool itself is very prone to absorbing condensation, which negatively affects its thermal insulation characteristics.

Ecowool, as an environmentally friendly material, is used for insulation and insulation of walls, floors and ceilings

There are two ways to apply this heat insulator to walls, the so-called “dry” and “wet”. The main difference and at the same time complexity of the second option is the need to use special equipment for this, the rental of which will cause quite high prices for insulating the ceiling using this method.

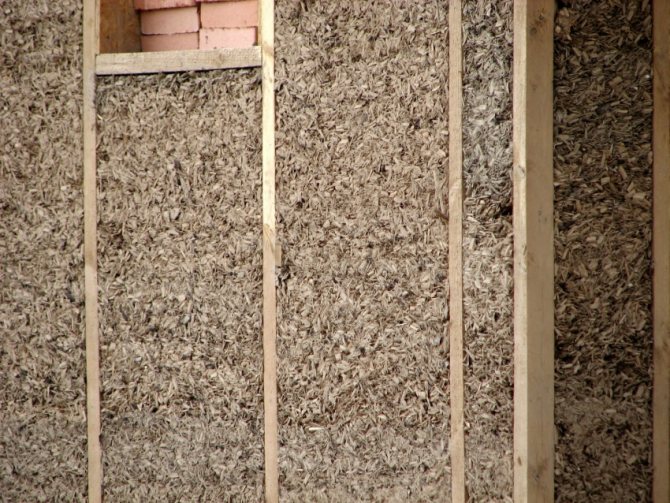

Insulating a bathhouse inside using a mixture of cement and sawdust

This method can confidently be called the oldest among all those described, since these materials were used for insulation long before thermal insulation materials such as polystyrene foam and mineral wool appeared on the market.

Interesting fact! Typically, cement and sawdust are used to create a suitable mixture. Although the option of replacing these components with clay and straw is quite acceptable.

First of all, prepare a dry mixture, which includes sawdust, lime and cement in a ratio of 10/1/1, respectively. After mixing all the dry ingredients, add 1.5 parts of water, pouring it in gradually and mixing thoroughly so that the solution is homogeneous. After this, all that remains is to place the mixture on the surface and level it to an even layer.

You can insulate a bathhouse from the inside using inexpensive materials such as cement and sawdust, mixing them in the correct proportions

Experts recommend using sawdust to create such a mixture, which has previously been dried for several months, or better yet, a whole year.

If all recommendations and technologies are followed, you can ultimately obtain high-quality, environmentally friendly material. Although we have to admit that in terms of thermal insulation characteristics it is still inferior to mineral wool and even expanded clay. So, perhaps, its only advantage is its low cost, which, however, entails quite a lot of hassle.

How to choose a material for insulating the ceiling in a bathhouse?

Construction organizations and individuals do not stop arguing for a day about what materials are best used to insulate the ceiling of a bathhouse and steam room from the inside.

Below we will look at materials for insulating the ceiling of a bathhouse and its walls from the inside.

Mineral wool

The material is made using limestone, basalt, dolomite and diabase.

In practice, it has been proven that products made from rocks and not from sawdust have the greatest resistance to high temperatures.

Necessary material properties that are necessary for insulating the ceiling with mineral wool:

- Fireproof mineral wool;

- The material is hygroscopic, i.e. a ceiling insulated with mineral wool perfectly absorbs moisture and dries quickly (the insulation does not rot or stink);

- Vata is famous for its durability. We used mineral wool once and that’s it, no maintenance or replacement of components in the future.

Mineral wool is used to insulate various buildings - and it does not matter whether it is residential or a room intended for other purposes.

You can treat the surface with mineral wool both inside and outside - the product is universal in its application.

Ecowool

The second most popular element for insulating ceilings and walls is ecowool, the closest “relative” of mineral wool.

Ecowool, unlike mineral wool insulation, contains natural components - thin wood fibers, which are the result of processing antiseptics and waste paper.

Most often, this type of wool is used to insulate the walls of residential buildings with your own hands. This material is also loved by professional builders.

For insulating the ceiling in a bathhouse and its walls, ecowool is also a good option.

Ecowool has the following positive properties:

- Despite the thinness of the fibers, it retains heat well;

- Cheaper compared to mineral wool due to simpler production technology.

Penoizol

Also, a material such as penoizol is suitable for insulating the ceiling and walls in a bathhouse.

The product is somewhat similar to polystyrene foam, but is the cheapest analogue of polystyrene foam; in domestic markets, penoizol is represented by a wide variety from various manufacturers.

Penoizol is in demand due to some features:

- The material is an excellent noise absorber;

- It has increased resistance to fire on a par with mineral wool;

- Thanks to its liquid structure, penoizol can fill even the most inaccessible places;

- Does not change its size when drying.

Expanded clay

Expanded clay is insulated less often than with previous names. At the same time, expanded clay insulation of ceilings, floors and walls is in high demand.

Expanded clay is best for insulating large buildings, i.e. The products have a decent weight when installed.

When insulating walls with expanded clay, you need to take care of waterproofing.

Penoplex

You can also insulate a bathhouse with penoplex.

Insulation with penoplex (or polystyrene foam) is excellent for do-it-yourself installation due to the low weight and shape of the blocks.

In addition, penoplex provides reliable thermal insulation for the ceiling and walls.

Other methods of thermal insulation of the ceiling in a steam room

The technology for performing thermal insulation using clay and mineral wool is as follows:

- For filing from below to the ceiling beams, an unedged board 5 cm thick is used.

- Outside, along the beams, a narrow board is attached using wood grouse. It is necessary to support the binder.

- Tongue-and-groove aspen boards are screwed to a fixed thin board; a ventilation gap must be left between them.

- Vapor barrier material is spread on the attic side.

- Then clay mixed with sawdust is laid in a 3 cm layer.

- Mineral wool is laid. You should take insulation with a density of 125 units and a width of 15 cm.

- To protect from the wind, a polypropylene film is laid.

- Finally, the attic floor is made from boards

If the bathhouse has a log floor, then the sheathing is first made, and then the sheathing is attached to it. Glassine is laid on top as a vapor barrier. Then sand is poured in a layer equal to 20 cm. The remaining actions depend on the wishes of the owner of the bathhouse.

To properly insulate a bathhouse, you need to know which insulation is best for a bathhouse on the ceiling, in what sequence the layers should be placed, as well as the features of insulating the ceiling in a steam room. The ceiling arrangement options described above can be changed depending on climatic conditions and personal preferences.

Technology

Mineral wool must be insulated from water vapor . To do this, it must be covered with a vapor barrier, which must be sealed and waterproof. Today, foil is often used for vapor barrier, taped at the joints with aluminum tape. Among the new products on the construction market is foil insulation, a modern material made on a fiberglass base. In addition, glassine, membrane insulation or ordinary polyethylene film are often used.

The bath ceiling may be:

- hemmed;

- panel;

- flat.

If the ceiling is hemmed , that is, the boards are hemmed to the floor beams, insulation must be done from the attic side. 2 layers of vapor barrier (glassine, roofing material, etc.), a layer of mineral wool, and again a layer of vapor barrier are laid on the ceiling.

To make the vapor barrier airtight, the joints can be sealed with foil tape. Next, you can lay boards on the floor of the attic.

In the case of a panel ceiling , each panel is covered with a vapor barrier film, mineral wool is laid on it and covered with a vapor barrier. All this is covered with boards.

The easiest way to insulate a flat ceiling . The technology here will be the same as in the case of a false ceiling. To do this, a vapor barrier is rolled out on the boards from the attic side, then a layer of mineral wool 200-250 mm thick is placed on it and completely covered with a vapor barrier. Next, the floor is covered with boards.

You will find out what the depth of the foundation for a bathhouse should be by reading this article. And here is an article about stones for the sauna stove.

Features of the arrangement of vapor barrier and waterproofing layers

The presence of a vapor barrier layer is not a whim, but a real necessity. Especially when it comes to rooms such as a bathhouse, where hot air is an integral part of using the room for its intended purpose. Rising in the form of steam, moisture can have a destructive effect on the insulation and contribute to the formation of mold and mildew on the wooden elements of the bathhouse frame.

Scheme of insulation and insulation of a bathhouse roof

In order to avoid problems that may arise as a result of moisture accumulation on the ceiling and walls, special films and coating materials are used, for example, anti-condensation membranes. When choosing a suitable material, it is advisable to purchase one that has a foil layer.

Helpful advice! During the installation of a vapor barrier film, it is very important to pay attention to its integrity. It is necessary to prevent the occurrence of gaps, as this will greatly affect the technical characteristics of the coating.

To ensure waterproofing, special films are used, which can be purchased at hardware stores. Sometimes the most ordinary polyethylene of sufficient density or cheap roofing felt is used.

To protect the bath frame from moisture, it is recommended to use a waterproofing membrane, which can be mounted in contact with the insulation without losing its properties

New technologies for insulating the ceiling in a bathhouse

Modern technologies make it possible to insulate a bathhouse reliably and efficiently. Insulation should consist of several layers. Thus, the room will be protected from cold and moisture.

The choice of modern materials depends on their quality, which has a direct impact on the cost of the material.

The heat insulator should not emit harmful elements during heating and exposure to moisture

The first layer of insulation material serves for thermal and vapor insulation. The second is to protect the first layer from condensation. Insulation materials can be purchased in specialized stores or online.

The best modern insulation:

- Basalt fiber. It has low thermal conductivity. This is a fire-resistant, natural material that completely loses its positive qualities when exposed to moisture.

- Expanded clay. High-quality material that can retain heat for a long time. However, for its effectiveness, a large amount of this material is required. Also, expanded clay alone is not enough; it requires additional insulation.

One of the old methods of insulation, which is still used today because of its cheap cost, is clay mixed with sawdust. It takes a long time to prepare. The boards are coated with clay on the outside and inside. It is important to understand that each material has its own characteristics and characteristics. For example, when insulating with mineral wool, you should ensure that there is a hole in the insulation for air to penetrate.

Do-it-yourself insulation of a floor ceiling: step-by-step instructions

A deck ceiling is an excellent option for buildings that are used seasonally and have a small area. But in such a design there is not a lot of space for bulk insulation. In addition, such a ceiling is also not able to withstand a lot of weight. Therefore, the choice of material should be approached more responsibly.

In order to have enough space for laying insulation, the floor ceiling should be placed slightly lower than the height of the walls. And after that, you can begin step-by-step work according to the following instructions:

- First of all, it is necessary to lay a vapor barrier layer on the attic side. In this case, the side on which the foil is located should be facing down. The material is laid with an overlap of approximately 10-15 cm, and to ensure tightness, you also need to tape the joints with tape.

- The selected thermal insulation material is laid on top. In this case, mineral wool or expanded clay is best suited, since the floor ceiling is not intended for heavy loads.

- A layer of waterproofing material is placed on top, which can be roofing felt or polyethylene film. Laying must be done with an overlap, and the seams must be carefully taped.

- The final layer should consist of sheets of plywood or boards, which will provide reliable protection for the previous layers.

The flat ceiling is easy to use, particularly in terms of insulation. If necessary, layers of insulators can be replaced without much effort

This is a simple method that is relevant if you do not plan to spend too much money and time on it. If the area of the bathhouse is large enough or it is necessary to use the space under the roof for storage, then this option will not be very suitable due to its fragility. In this case, it is better to give preference to a false ceiling.

How to insulate a bathhouse ceiling: the best thermal insulation materials

During the heating process, the temperature and humidity in the room reaches extremely high levels. Therefore, special requirements are imposed on the building materials that are used in the process of arranging this room, namely, they must be resistant to such influences and not emit hazardous substances when heated.

In addition, it is not recommended that the weight of the insulation be too large. It is preferable to choose a lightweight material that is simple and convenient both in transportation and installation. And of course, we must not forget about such a characteristic as fire resistance, which is important for such a room as a bathhouse.

The modern market offers a wide variety of insulation and insulation materials for buildings, so it is quite easy to choose high-quality material based on their required characteristics and financial capabilities.

Do-it-yourself insulation of a bathhouse ceiling: advantages and disadvantages of mineral wool

Mineral wool is by far the most popular option among all. It is often used for insulation not only of bathhouses and garages, but also for residential buildings. In itself, it is a fibrous material that has excellent thermal insulation characteristics and can be presented in one of three types:

- glass wool;

- stone wool;

- slag wool.

But if the first option is familiar to almost everyone, then not everyone has seen the other two. Rock wool is a material made primarily from basalt, although it is sometimes made from other rock melts. Slag wool is very similar to cinder blocks, for the production of which blast furnace slag is used.

Mineral wool is characterized by significant resistance to high temperatures and also has excellent heat and sound insulation properties

In addition to the fact that mineral wool has low thermal conductivity, which allows it to be used for thermal insulation of ceilings and walls, it has another significant advantage. Unlike other materials, it cannot serve as a breeding ground for microorganisms: fungi, mold, small insects or rodents, which is very useful for summer cottages.

As for other characteristics, mineral wool is not prone to fire and does not react in any way to temperature changes: it does not deform or shrink. Light weight and convenient packaging (usually in the form of rolls or rectangular slabs) make it easy and convenient to work with the material, even alone.

Of course, this material also has disadvantages that one way or another will have to be taken into account:

- mineral wool can absorb moisture;

- it contains phenols, which can potentially pose a hazard to human health.

Insulation with mineral wool is necessarily accompanied by additional waterproofing of the surface

Both of these disadvantages can be neutralized during the installation process, providing the insulation with high-quality vapor and waterproofing, completely eliminating the risk of contact of mineral wool with air under the ceiling. This is especially true for warm and humid air, which is concentrated indoors.

Helpful advice! Despite the fact that, if all installation rules are followed, mineral wool does not pose a real threat to health, during its installation it is necessary to be careful and use protective equipment, since its small fibers can cause irritation to the skin and eyes.

Insulation of the ceiling in a bathhouse with expanded clay: features of use

Expanded clay is small-sized pebbles that consist of clay and have a porous structure. If we take into account all the factors, then expanded clay can be called the most suitable material for insulating the ceiling in a bathhouse. Of course, if the building has attic space and there is a possibility of using it.

Distinctive features of expanded clay as an insulation material are the high hydrophobicity of the material, as well as resistance to the development of microorganisms and fungi

The advantages of this choice can confidently include the following aspects:

- expanded clay is completely safe: it does not support combustion, is environmentally friendly and even in the event of a fire will not release hazardous substances into the atmosphere;

- over time, as well as under the influence of external factors, expanded clay does not deteriorate and does not decompose;

- the cost of the material is quite low;

- bacteria and fungi do not consider expanded clay an attractive environment for life.

In addition, expanded clay is superior to mineral wool in its ability to not absorb moisture. And although the need to equip steam and waterproofing layers remains, the risk of moisture accumulation inside the insulation layer is much less. It should also be noted that the service life of expanded clay is one of the longest when compared with other materials.

Expanded clay can be used to insulate both ceilings and floors

Is it worth it to insulate the ceiling from the inside with polystyrene foam?

At a certain period, foam plastic was the leader among thermal insulation materials, which were used to insulate not only bathhouses, but also residential buildings. But with the advent of alternative options, its significant shortcomings became noticeable. So, for example, in the event of a fire, polystyrene foam burns well, while also emitting toxic smoke that can harm human health.

In addition, polystyrene foam is not very resistant to external factors, collapsing under the influence of high temperatures, which is inevitable if it is used in a bathhouse.

For these reasons, we can conclude that polystyrene foam is far from the most suitable material for this purpose and it is better to give preference to another material that is more stable and suitable for its characteristics.

Many builders prefer to insulate the ceiling of bathhouses with penoplex foam with a thermal layer rather than polystyrene foam

Using ecowool as insulation for a bath

Another material that is popular among insulation materials and is often used for bathhouses and garages is ecowool. This fibrous material is made from cellulose, adding special impurities to it to provide protection against insects, bacteria and rodents. In addition, they make ecowool resistant to fire.

The advantages of this material include environmental friendliness, as well as low weight and the ability to fill even the smallest cracks and gaps, which is very convenient when it comes to working with a not too smooth surface. It does not emit any toxic substances so, like expanded clay, it is completely safe for human health.

But there is also a significant drawback: the effectiveness of using ecowool is directly related to the presence of ventilation, as well as a high-quality waterproofing layer, which is designed to remove moisture. This is due to the fact that ecowool itself is very prone to absorbing condensation, which negatively affects its thermal insulation characteristics.

Ecowool, as an environmentally friendly material, is used for insulation and insulation of walls, floors and ceilings

There are two ways to apply this heat insulator to walls, the so-called “dry” and “wet”. The main difference and at the same time complexity of the second option is the need to use special equipment for this, the rental of which will cause quite high prices for insulating the ceiling using this method.

Insulating a bathhouse inside using a mixture of cement and sawdust

This method can confidently be called the oldest among all those described, since these materials were used for insulation long before thermal insulation materials such as polystyrene foam and mineral wool appeared on the market.

Interesting fact! Typically, cement and sawdust are used to create a suitable mixture. Although the option of replacing these components with clay and straw is quite acceptable.

First of all, prepare a dry mixture, which includes sawdust, lime and cement in a ratio of 10/1/1, respectively. After mixing all the dry ingredients, add 1.5 parts of water, pouring it in gradually and mixing thoroughly so that the solution is homogeneous. After this, all that remains is to place the mixture on the surface and level it to an even layer.

You can insulate a bathhouse from the inside using inexpensive materials such as cement and sawdust, mixing them in the correct proportions

Experts recommend using sawdust to create such a mixture, which has previously been dried for several months, or better yet, a whole year.

If all recommendations and technologies are followed, you can ultimately obtain high-quality, environmentally friendly material. Although we have to admit that in terms of thermal insulation characteristics it is still inferior to mineral wool and even expanded clay. So, perhaps, its only advantage is its low cost, which, however, entails quite a lot of hassle.

Do-it-yourself insulation of a false ceiling: step-by-step instructions

The design of a suspended ceiling involves attaching to the upper part of the wall not the flooring itself, but support beams, for which a wooden beam or several boards spliced together are most often used. A ceiling is attached to the beams above and below, which also serves as the floor of the attic. Well, in the middle between the top and bottom layers a layer of thermal insulation material is laid, as well as hydro- and vapor barriers.

The installation process may differ slightly depending on which insulation was chosen, however, in general, the technology remains the same. If mineral wool is used for this purpose, the procedure is as follows:

- The first layer of waterproofing material is laid, which is attached to the upper surface of the beams using a furniture stapler. As in all other cases, the overlaps must be at least 10 cm, and the joints must be additionally glued;

Scheme of arrangement and insulation of a false ceiling

- boards or plywood are laid on top of the waterproofing, thus ensuring strength and reliability of the structure;

- mineral wool of suitable thickness is placed in the spaces between the beams based on the following standards: 150-180 mm for regions with a temperate climate, 200-250 mm for regions characterized by severe frosts. As with waterproofing material, the connection of two separate parts of the material must be overlapped;

- The vapor barrier film is attached to the floor beams from the bottom side. It is highly recommended that its edges be attached to the top of the walls. Since this is a very delicate material, it is important to work with it carefully, avoiding damage and tearing;

- perpendicular to the beams, wooden slats are attached on top of the vapor barrier material;

- The final stage is attaching the lining using self-tapping screws or nails to these slats.

This insulated ceiling is very durable and can withstand heavy loads, so the attic space can be used to create an attic or as storage for various accessories.

The final layer of bathhouse ceiling insulation is the installation of a vapor barrier film, which must be handled quite carefully

Laying thermal insulation

To properly insulate the ceiling of a bathhouse with your own hands, you need to nail a sheathing perpendicular to the floor beams, which will serve as support for thermal insulation (the ceiling sheathing will then be attached to it).

Insulation, the thickness of which should be at least 200-250 mm, is placed tightly, without tension, in the space between the beams on top of the vapor barrier. It is desirable that the distance between the beams be small, because that is when the mineral wool will lie without gaps and cracks.

It is worth noting that it should also not be crushed too much, since in this case it may lose some of its heat-protective properties.

The thermal insulation layer needs protection from moisture, which can reach it through the roof of the bathhouse. For this reason, such a procedure as insulating the ceiling of a bathhouse with your own hands must be completed by laying waterproofing. As such a waterproofing layer, it is quite possible to use thermal film or ordinary polyethylene. In order to ensure a good level of ventilation, free space must be left between the layers of thermal insulation and waterproofing.

Do-it-yourself insulation of the ceiling of a bathhouse without an attic: nuances of work

The technology for insulating a wooden or panel bath, in the case of a complete absence of an attic space, has some differences from those discussed earlier. In this case, it is necessary to secure the vapor barrier material, and then attach the insulation itself. The beam beam and the final layer - ceiling boards - are already attached to it.

Particular attention should be paid to the junction of the insulation and the pipe. First of all, this is necessary to ensure compliance with fire safety standards. The indentation provided for by the rules must be at least 200 mm. Naturally, you can’t just leave a hole, and therefore a simple box consisting of rafter legs is mounted. Its main role is the separation of insulation and pipes.

Helpful advice! The inside of the box can also be filled with thermal insulation material. True, it must be fire-resistant and not susceptible to high temperatures. For example, stone wool is suitable for this.

Before laying layers of insulation and insulation, it is recommended to treat the wooden ceiling with special means to eliminate the possibility of the development of harmful bacteria and fungi

Another important task that faces the owner who is insulating the ceiling of a bathhouse without an attic is to completely eliminate the risk of condensation. Therefore, all vapor and waterproofing materials must be of high quality and attached in strict accordance with the rules and regulations.

Why is it necessary to insulate the ceiling in a bathhouse: structural features

A bathhouse is a room that is periodically heated for the purpose of taking health procedures. A special microclimate is formed inside the room, characterized by high temperature and humidity. Of course, this cannot but have an impact on those building materials that have to be exposed to such influence.

Arranging a bathhouse requires special attention in terms of hydro-, steam- and thermal insulation

In addition, one has to take into account the costs associated with the use of this or that amount of fuel. If a building is prone to cooling quickly, large amounts of fuel will be required to maintain the appropriate temperature. And given the fact that, according to the laws of physics, warm air is lighter than cold air, it is the roof of the bathhouse that requires insulation, through which significant heat loss occurs.

But on the way to erecting a barrier to retain warm air indoors, there is one more aspect that all bathhouse owners should pay special attention to. High humidity becomes a source of large amounts of condensation, which, if the roof is not insulated correctly, can accumulate. This often causes the destruction of wooden elements of the structure.

Interesting fact ! High humidity is a favorable environment for the growth and development of various microorganisms: fungi, mold and bacteria. Ill-conceived vapor and heat insulation can cause them to appear and multiply.

Materials for insulation and insulation of the bathhouse are selected depending on the type and size of the building

How to insulate concrete floors

If you are completely confused by the wide range and do not understand what material to use, then take the advice of experienced builders. For example, with concrete floors it is recommended to use expanded clay.

No special preliminary preparation is required. For convenience, timber slats can be attached to the base of the roof. This will make it easier to check the uniformity of expanded clay distribution. Although this condition is advisory in nature.

So, pour expanded clay (30 cm thick) over the entire surface. An ordinary garden rake will help distribute the granules evenly. If the attic space will be used in the future and a floor is provided, then expanded clay is laid level.

If all the backfill is leveled, you need to lay the GIP. Durable polyethylene is quite suitable. It is distributed with an overlap of 10-15 cm. Scotch tape is glued to the joints.

If you want to make a floor, then planks are laid on the beams.

This is a fairly cheap and easy-to-follow method that will help you insulate the ceiling in a bathhouse with your own hands. But because it is cheap, it does not become less effective.

Insulation from the room side

It is also necessary to consider how to insulate the ceiling in a bathhouse with mineral wool from the inside. With this method of thermal insulation, it is better to use stone wool. Before insulation, waterproofing material is laid on the floor beams from the attic side. A plank covering is laid on top of it.

After this, the insulation of the ceiling with mineral wool will be carried out indoors. The heat insulator is placed between the beams. If their width is not enough, additional slats are attached. The distance between the beams should be 3-4 cm greater than the width of the insulation boards. This is necessary so that the panels are spaced.

How to insulate the ceiling with mineral wool in an already built bathhouse? To do this, you need to attach guides to the ceiling. The first step is to mark using a building level. Mark the lines along which the guides will be installed. The distance between the slats is adjusted to the dimensions of the insulation boards so that the material is tightly fixed between the guides.

The wooden frame is fixed with self-tapping screws every 50-60 cm. Metal slats are attached to special hangers. With their help, you can adjust the distance to the ceiling and fix the insulation, which does not hold tightly, with bent parts.

When the work on laying mineral wool is completed, vapor barrier work begins. The instructions for its installation provide for a sealed coating. To do this, the fabrics must overlap and the joints must be taped. Then wooden slats are attached to the beams on top of it. Decorative lining will be screwed to them.

Only the correct fulfillment of all conditions will ensure high-quality thermal insulation of the room. However, if you have doubts about how to insulate the ceiling in a bathhouse with your own hands, or are not confident in your skills, it is better to seek help from professionals.

How to insulate the ceiling in a bathhouse from the outside

How to insulate the ceiling in a bathhouse from the outside - the main task of insulating the ceiling from the outside is to create a “thermos” effect. The heat that is pumped inside the bath should not escape outside.

To solve this issue, traditional modern materials are used: expanded clay, mineral wool and others in combination with waterproofing barriers.

Very often, professionals use the “layer cake” insulation method. To do this, the bathhouse ceiling is lined with blocks about 6 centimeters thick.

Then a layer of vapor barrier (aluminum foil or cardboard) is laid. And the final stage is insulation with expanded clay, sand, mineral wool or clay with sawdust.

How do you insulate the ceiling in a bathhouse?

If you analyze the market for modern materials that can be used to insulate the ceiling surface of a bathhouse, you can find a large number of options there. Moreover, environmentally friendly materials .

These are considered to be sand, shavings, earth and sawdust used in the form of a mixture with a clay solution. Thanks to the development of new technologies, new materials are now available to consumers - expanded clay and mineral-based insulation.

It is advisable to avoid using polystyrene foam as a thermal insulation material. The reason for this is due to its high fire hazard and toxicity. Also, using a combination of wood and plastic when constructing a ceiling does not seem to be the best solution.

To finish the ceiling of log baths, boards are most often used, the minimum thickness of which should be 6 cm . They are used in combination with aluminum foil fixed to the surface of the boards, which increases the energy-saving effect. After this, they begin to create a layer based on clay with sawdust and mineral wool.

During work, it is necessary to maintain the required distance by which the materials used must be removed from the pipe. The optimal step is considered to be 20 cm. To fulfill this requirement, it is necessary to make a box based on the rafters, the internal space of which, as well as the area between it and the pipe, is filled with stone wool.

The quality of the work performed on thermal insulation and vapor barrier of the bathhouse ceiling can be greatly influenced by the design of the ceiling.

A similar bathhouse element can be made in the following options: floor-mounted, panel-mounted.

Insulation of a suspended ceiling

A special feature of such a ceiling is the presence in its design of a supporting frame made on the basis of beams .

- The installation of these beams is carried out in a special way, and additionally the lining must be done with edged boards;

- The space formed by the vapor barrier and waterproofing layers is filled with insulation;

- Next, they begin sewing up the ceiling structure, using boards for this.

For the design under consideration, the most preferable option is a thermal insulation device based on expanded clay. This option is most suitable for bath buildings that include an attic space.

Insulation of a flat ceiling

To make such a structure, boards are used that are laid on the walls. You should be especially careful when choosing boards, which should have a minimum width of 5 cm.

When the ceiling is ready, they begin to attach a vapor barrier layer to it. Next, they proceed to installing slabs based on mineral insulation. Having decided to create such a ceiling structure, the owner will incur minimal costs for its manufacture, and he will also need less time and effort to install it. But at the same time, such a ceiling also has a serious disadvantage, which is that this design can only be used for small baths that have an attic.

Insulation of panel ceiling

The procedure for installing a panel vault in a bathhouse involves the use of special shields. The main elements are load-bearing bars, internal lining, as well as a vapor barrier layer and a heat and waterproofing layer . Mineral wool is used as insulation for such structures.

Thermal insulation installation technology involves filling the space between the panels with a material that has moisture-proof and heat-saving properties. As such, you can use felt with a foil pad. The main difficulties when installing a panel structure are related to the weight of the panels, which is why one person may not be able to complete the work.

According to experienced bathhouse owners, among all designs, the panel option is the most preferable. The fact is that even against the backdrop of high manufacturing costs, it is characterized by amazing strength, high convenience and long service life.

How to insulate a bathhouse ceiling inexpensively

The most economical, but labor-intensive option for insulating the ceiling in a bathhouse is the use of sawdust, clay and sand. Roofing felt or isolon is laid in the attic with an overlap of at least 10 centimeters.

Then a thick layer of sawdust of at least 20 centimeters is poured, and the top is insulated with earth or clay. It is better to take sawdust from carpentry, as the shavings are drier and lighter.

The downside is that thermal insulation solely depends on the density and thickness of the insulation layer.

The use of mineral wool is also considered one of the inexpensive ways to insulate the ceiling.

The presence of an attic is not necessary. The main thing is the presence of floor beams on which the material can be attached.

Thus, we can conclude that not all insulation methods are expensive and require special training. Subject to the availability of high-quality material, as well as compliance with technological recommendations, you can be sure that the necessary heat in the premises will be maintained.

The need to use a vapor barrier

Insulating a bathhouse ceiling with your own hands should begin with choosing a vapor barrier, which is necessary to ensure that the thermal insulation layer performs its functions for as long as possible. Of the many types of vapor barriers for baths, it is best to choose foil insulation - a glass-fabric-based material covered with a layer of aluminum foil. Such a vapor barrier will not only protect the mineral wool from getting wet and losing its heat-retaining properties, but will also act as a heat reflector, which will reduce the cost of maintaining the desired temperature several times.

Laying foil insulation or other vapor barrier materials of your choice (for example, membrane vapor barrier or foil insulation) must be done with an overlap of at least five centimeters. Having secured the foil insulation with a construction stapler, the seams must be additionally taped to prevent the slightest cracks or holes for the passage of steam. Only in the case of complete tightness, insulating the ceiling in a bathhouse with mineral wool with your own hands will provide you with the desired result.

Expert advice

We went through popular YouTube channels, where they talk about baths authoritatively, knowledgeably, by people whose opinions we ourselves listen to. But the only problem is that they talk about a lot of things, but for some reason the problem of insulating ceilings, as well as the choice of materials, does not attract everyone’s attention.

Therefore, don’t blame me, the example of expert advice on ceiling insulation will be the video below, made - we simply couldn’t find anything more significant.

But what’s interesting is that you won’t hear standard descriptions in it. On the contrary, the authors of the video turn to the experience of previous generations and offer the most budget-friendly, simplest option for organizing both the ceiling itself and its insulation - this is a completely simple floor ceiling, insulated... with sawdust and clay. It couldn't be simpler.

You don’t even need to bother with the lining - you can make the flooring boards into a finished ceiling if you plan and sand them first.

Of course, any opinion will be controversial, and you have the right to question it or not consider it an expert.

***

Now that it is already clear why a ceiling without insulation is a waste of heat, all that remains is to wish every owner that in any weather his bathhouse will warm up properly and keep warm for the second day.

Advantages of mineral wool for insulation in a bathhouse

Mineral wool practically does not conduct heat, it is safe and environmentally friendly, and at the same time it allows you to isolate the room from extraneous sounds. Another advantage of mineral wool is that insects and rodents do not grow in it, it does not rot, and is not susceptible to mold.

Mineral wool as insulation in a bathhouse can easily withstand mechanical loads and is durable. This insulation material is fireproof, easy to install and has a long service life. When laying it, it should not be compacted or crushed, as this affects the quality of thermal insulation. All possible evaporation of water should be excluded, as this leads to a deterioration in the beneficial properties of mineral wool.

Video - We insulate the ceiling in a bathhouse with a cold roof using mineral wool

The process of insulating the shed ceiling of a bathhouse with a cold roof looks a little different when expanded clay or a cement-sawdust mixture is used. Let's present this in the form of step-by-step instructions.

Ceiling insulation scheme with expanded clay

- A rough flooring made of boards is laid on the floor beams below. The gaps between them must be treated with sealant or coated with a mixture of clay (or concrete) and sawdust.

- A vapor barrier film is laid on the flooring both from the steam room side and from the roof side, and not only the boardwalk should be covered, but also the beams themselves.

- Expanded clay is poured into the resulting boxes or ecowool is laid.

- Roofing felt or other waterproofing material is laid over the insulation overlapping and secured to the beams using a construction stapler.

- Boards or plywood are laid over the waterproofing to form the attic floor.

- The lining is laid underneath on the rough boards.

Insulation of a false ceiling with expanded clay

If you use a mixture of clay and sawdust to insulate the ceiling, then it is advisable to put a layer of mineral wool on top of the frozen mixture or fill it with expanded clay - this will improve the thermal insulation performance.

Important! The optimal layer thickness of a mixture of clay and sawdust for using a bathhouse in the warm season is 50 mm. If you plan to steam in it in winter, then you will need to make a layer of insulation of at least 150 mm.

What materials are good for insulating a bathhouse ceiling?

Technical felt

Technical felt

Technical felt is an excellent natural insulation material, which, unfortunately, is not sold on the construction markets. It can only be purchased from manufacturers. Coarse wool felt with a thickness of 30 mm and a density of 0.32 g/sq.cm is suitable for insulation. Actually insulation is 1 sq. meter of technical felt would cost 10 times more if the ceiling were insulated with basalt wool or polystyrene foam (which cannot be done at all).

Natural technical cork

Black cork agglomerate

Natural technical cork or black cork agglomerate (but not cork coverings), produced only in Portugal.

Sheets have dimensions 915*610*10-50 mm or 1000*500*10-100 mm. Cork is not hygroscopic and is not susceptible to rotting or mold. It is lightweight and easy to install. Withstands temperatures from -180 to +115 degrees, with an average density of 90 – 135 kg/cu. This is perhaps one of the most expensive methods of ceiling insulation;

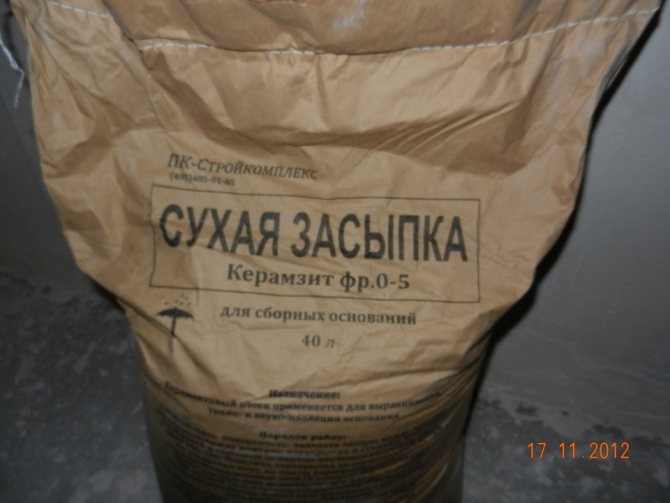

Expanded clay sand

Expanded clay sand (dry expanded clay backfill)

Expanded clay sand (dry expanded clay backfill)

Expanded clay sand is one of the best options for insulating the ceiling in a bathhouse. Insulating the ceiling with expanded clay is not at all difficult. For high-quality thermal insulation, you need to take expanded clay sand with a fraction of 1 to 5 mm from a trusted manufacturer.

You can verify the quality of expanded clay by performing a visual analysis. The granules must be in the declared sizes, “chocolate” color without visible deviations.

The insulation layer must be at least 80 mm. Expanded clay is not a hygroscopic material, but moisture that gets into the pores will evaporate for a long time and create excessive parkiness in the attic. Therefore, expanded clay must be well protected from steam penetration using a properly made vapor barrier;