Wood concrete masonry

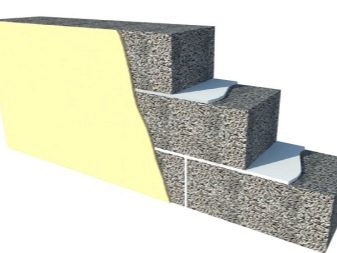

Arbolite blocks, purchased or made independently, have the correct geometry, so their laying is not very difficult.

Arbolite blocks, purchased or made independently, have the correct geometry, so their laying does not present any great difficulties. As a masonry mortar, ordinary cement-sand mortar is used in a ratio of 1:4 (cement m-400 and sand, respectively). It is recommended to make the consistency of the solution semi-liquid, since wood concrete actively absorbs moisture.

Laying is done in the usual way. First, the corners are raised with careful control of verticality, after which, according to the resulting seams, the threads are stretched along which the row masonry is made. If it is necessary to cut blocks, use an angle grinder (grinder) with a disc for concrete or, as an option, an electric or chainsaw. These same tools will help you make blocks of irregular geometry if the need arises.

Upon completion of the laying of the last row, to strengthen the building, it is recommended to make an armored belt, which significantly increases the strength of the structure and prevents possible horizontal movements of the walls. Another purpose of the armored belt is to carry the load of the roof or floors.

To make an armored belt, you need to install low (up to 10-15 cm) vertical formwork around the perimeter of the walls built with wood concrete, tie it with reinforcement and fill it with ordinary concrete. After the armored belt has stood for 1-2 weeks, the surface is isolated from moisture (similar to waterproofing between the foundation and the masonry), a mauerlat is laid around the perimeter, from which roofing work begins.

Wall masonry

Wood concrete walls can be erected in two ways:

- Wall made of arbolite blocks.

- Monolithic wall made of arbolite mortar.

The first method is quite simple. All you need to do is purchase the blocks and get to work. The laying is done in exactly the same way as laying ordinary bricks. There are just some nuances. Before installing the blocks, they need to be moistened, since wood concrete can draw liquid out of the binder composition, because it absorbs moisture well.

Cutting arbolite blocks

You need to start laying blocks from the corner. It is also important to ensure that the horizontal line is straight. For convenience, you can use a cord. Place two corner blocks perfectly level, stretch a rope along their edge, which will serve as a guide for even laying. Using the trowel handle, the blocks can be adjusted to the line by tapping them from above.

Arbolite mortar is poured into the formwork

To proceed according to the second method, you need to make your own wood concrete mortar and formwork. As a result, you should have monolithic walls. To make the solution, you need to prepare a trough with low sides where the mixing will take place. The procedure for making the solution is as follows:

- Sawdust and shavings are poured into the trough, which serve as filler.

- All this is poured with limestone milk, after which mineral additives are added.

- Then this mass must be mixed carefully. For this purpose, it is better to use a garden hoe rather than a shovel.

- Now you should add cement and mix the mixture thoroughly until smooth.

- Gradually add water, stirring the entire solution.

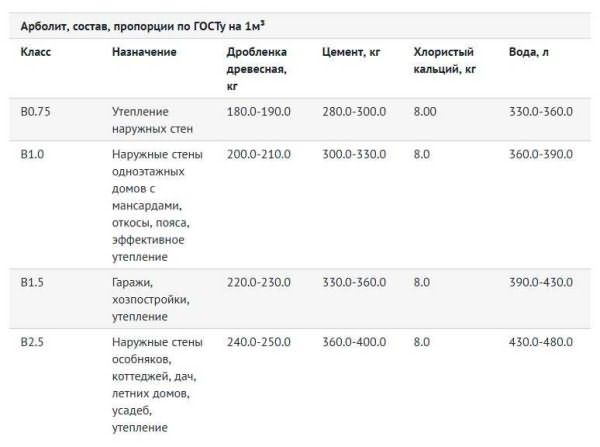

On average, to make 1 m3 of wood concrete, you will need:

- organic filler (sawdust from coniferous or hardwood) – 250–300 kg;

- Portland cement 300 grade – 250–300 kg;

- lime – 8–10 kg;

- calcium chloride (as a mineral supplement) – 6–8 kg;

- water – 350–400 l.

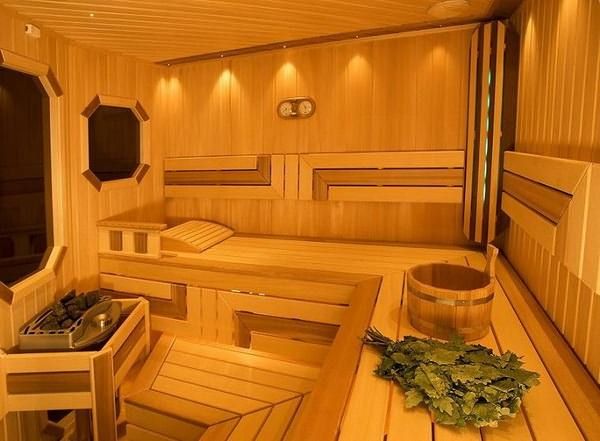

We invite you to read: Do-it-yourself sauna: what is it, benefits and harm

Slate flat

Care should be taken to install the formwork in advance. It is better to choose removable or sliding formwork, the height of which is 1–1.2 m. It is better when the formwork is made of asbestos-cement sheets (flat slate). The inside can be coated with limestone milk. It is important to securely secure the formwork that is installed on the foundation. To do this, use tie bolts with bars. The edges on top must be supported with jibs.

After everything is ready, the wood concrete solution can be poured. It is important not to fill the entire formwork to the brim. It is better to pour the mass in a layer of no more than 50 cm at a time. Then everything must be compacted and left to dry. If the temperature is 18–20ºC, the composition will harden in 2–3 days, and if the temperature is lower, it will harden in a week.

Once everything has frozen, the formwork is removed. It is important to do this carefully so as not to damage the composition, carefully removing bolts and boards. After this, the formwork is attached higher, to the finished wall, and the process is repeated until the wall reaches the desired height. Wood concrete is a hygroscopic material, so the walls need to be protected from dampness so that they do not collect moisture.

Wood concrete wall decoration

Design

In the process of creating a project, the composition and characteristics of the soil are determined in order to calculate the characteristics of the foundation in accordance with this information. Then the shape of the house, the thickness of the walls, the presence or absence of thermal insulation, the placement of windows and doors, as well as other necessary characteristics are established. In addition, during the process of creating a project, the quantity and type of building materials are determined.

For example, on the outskirts of the city of Sochi, a wall thickness of 20 centimeters makes it possible to do without thermal insulation, while in the Omsk area the smallest wall thickness, which allows one to do without the use of thermal insulation, is 50 centimeters.

A competently created project will save you from unnecessary consumption of materials and the possibility of rebuilding some areas or details during the construction of the house.

Projects of houses made of wood concrete with an area of 100 to 150 square meters. m can be one-story or two-story and have in its structure an attic, a garage and even a basement or ground floor.

How to choose a bathhouse project?

If you have firmly decided to use wood concrete, it is time to decide on the dimensions. Quite often, a bathhouse on a suburban site is built with a second residential floor, and in this case, the search for a suitable project has its own characteristic features. The total size of the building is selected according to how many people will use it at the same time. For the constant, systematic use of a bathhouse of this kind, it is necessary to build an almost complete suburban dwelling. In this case, it is also recommended to choose projects that allow, in addition to the steam room, to place on the ground floor a leisure room, a gym and some other utility rooms.

Since even when using lightweight wood concrete, the total mass of a two-story bathhouse is quite large, placing it on a lightweight columnar base is irrational.

As for heating, perhaps the best choice is heating with a double-circuit gas boiler. At the same time, on the ground floor, in order to maintain traditions and the necessary color, an ordinary heater stove is installed.

In places with a harsh climate, it is useful to place such water sources inside the bathhouse itself. For obvious reasons, it is worth placing a staircase leading to the second floor inside. Since it is difficult to place everything you need in a limited area, sometimes you have to turn to professionals to create an individual project.

Comparison of wood concrete with other materials

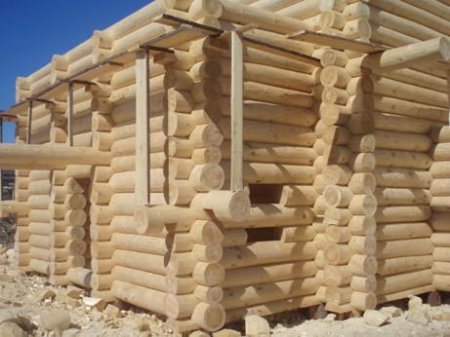

The first indicator is thermal conductivity. Everyone knows the basic requirement for a bath - it must be warm. According to this characteristic, it is from wood and wood concrete that the bathhouse will warm up very quickly, especially in the cold season. Therefore, projects for winter baths are ordered from this material, as well as from a log house. Brick, with its lowest thermal conductivity, takes too long to warm up and retains heat worse than others.

The second indicator is strength. Every bathhouse owner tries to do everything possible to make his structure as durable as possible. Of course, wood concrete, although inferior to brick structures, is several steps ahead of other materials, for example, wood.

The third indicator is moisture resistance. Taking into account the constant humidity in the bathhouse, it is better to choose a “breathable” material that will not rot and can retain its shape. In this case, wood concrete outperforms natural wood (saunas made of logs, timber, logs), since it is not subject to deformation due to its structure and physical properties, i.e. will not shrink or crack.

The fourth indicator is fire safety. According to this characteristic, the most reliable is brick (it does not burn at all), and the most dangerous is wood. But wood concrete is the “golden mean,” which also gives it an additional advantage.

It is necessary to insulate an arbolite wall with special ventilated gaps so that the arbolite can breathe.

The fifth indicator is biosecurity. In this case, wood concrete is much better than wood, because it is not chewed by pests, harmful microorganisms do not form mold on it, and it is resistant to rotting. According to this indicator, it is best to build baths from wood concrete, foam blocks and bricks.

The sixth, important indicator is cost. Construction using this material has a very competitive price, which is significantly lower than that of brick and natural wood. In addition, the lightness of wood concrete allows you to avoid the cost of constructing a massive foundation. In this case, a strip foundation is suitable, although depending on the terrain and soil conditions, this material may well be able to implement the bathhouse project prepared for you on screw piles.

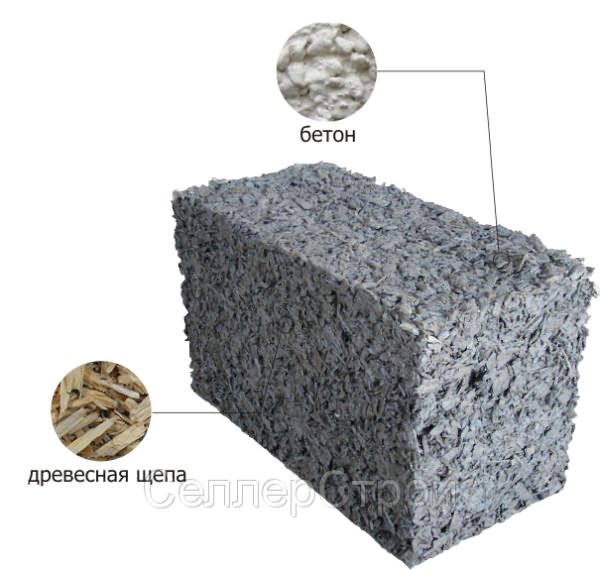

What is wood concrete

The name itself comes from the French word arbre, which means “tree”. It is also called “wood concrete” and is made from 3 main components:

- Filling in the form of crushed rice straw, flax, cotton stalks, pine needles, bark, but most often - wood chips (spruce, pine, beech), up to 25 cm in length and 1 cm in width.

- The binder is cement grade of at least M300.

- Stabilizers that regulate improved adhesion of components, as well as the degree of hardening of the material, its plasticity - additives of chemical origin, mainly aluminum sulfate, calcium chloride and nitrate, as well as liquid glass and so on.

The quality of the resulting material is regulated by established GOST or TU standards.

Features of wood concrete, is it possible to build a bathhouse from blocks

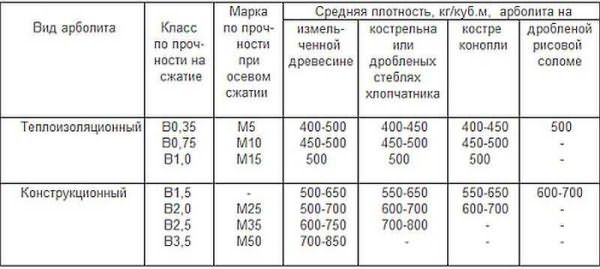

Manufacturers produce two types of wood concrete block products with different densities:

- thermal insulation – 400-500 kg/m3;

- structural - 550-800 kg/m3.

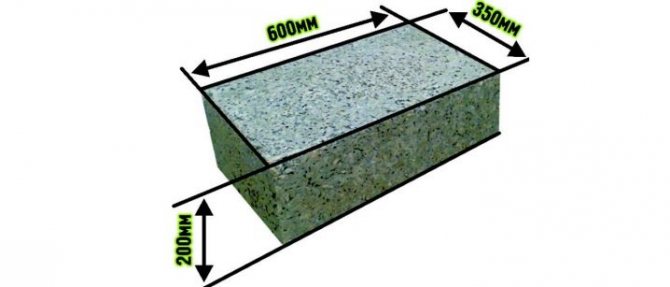

The density depends on the proportions of the mixture and the caliber of the chips. In factory-made structural arbolite blocks, its dimensions vary within strict limits: length - up to 25 mm, width - up to 10.

To evaluate the quality of a wall made of wood concrete, it is worth comparing its characteristics with brick, wood and sawdust concrete. Table 1 provides reference data for each of the materials.

| Parameter | Arbolit | Ceramic brick | Wood | Sawdust concrete |

| Average density, kg/m3 | 600 | 1550 | 500 | 1100 |

| Compressive strength, MPa | 0,5-1,0 | 2,5-25 | 2,7-6,2 | 2-2,5 |

| Bending strength, MPa | 0,7-2,5 | 2,7-3,2 | 5,8-7,9 | 2-2,8 |

| Thermal conductivity, W/(m*оС) | 0,12 | 0,6-0,9 | 0,14 | 0,2-03 |

| Frost resistance, cycles | 25-50 | 25 | — | 50 |

| Water absorption,% | 40-85 | 12 | 30 | 60-80 |

| Fire resistance | does not support fire (0.75-1.5 h) | Incombustible | highly flammable | flame retardant |

| Biostability | Group V | bioresistant | is rotting | Group V |

Judging by the data in the table, the design and construction of a home bathhouse made of wood concrete is completely justified, since this composite material has properties that are important specifically for a bath house:

- minimal thermal conductivity - a 30-centimeter block of wood-concrete in this indicator can be compared with a brick wall 95 cm thick;

- environmental friendliness - when wood concrete is heated, no harmful substances are released;

- light weight - due to this, construction can be carried out on a low-cost lightweight foundation;

- high fire resistance;

- plasticity - it allows you to do without reinforcement when constructing small buildings.

Unlike wood, concrete filled with wood chips is not prone to rotting due to moisture absorption; it allows steam to pass through due to its porous structure. As reviews indicate, if the finishing is done correctly, the bathhouse will retain heat well, and condensation will not appear on the walls.

It is worth noting that a sawdust concrete bathhouse is more massive compared to an arbolite bathhouse - in order to retain heat, the walls must be 1.5 times thicker. If you neglect this requirement, heating costs will increase.

How to choose a wood concrete block

Due to the ease of manufacturing the block and the availability of its components, many privately produced wood concrete blocks have appeared on the market. Like foam concrete, wood concrete produced with violations of the production technology is often found, which is, accordingly, of poor quality and unsuitable for use.

How to identify high-quality wood concrete and not buy a fake?

Experts advise paying attention to indicators such as:

exfoliation index (heterogeneity). The block should not be divided into component parts. According to GOST, this figure should not exceed 10%;

lack of certificate. Arbolite blocks are subject to certification

By the way, pay attention to the authenticity of the certificate. Although, having documents is a dubious advantage, because

everything is sold and bought, including certificates of quality and conformity;

significant violations of the block geometry. They can be caused by two factors: either the presence of chips of different sizes, which is unacceptable, or poor-quality equipment or a violation of production technology;

color and foreign matter. Various shades of green and brown indicate that the block is not sufficiently dried at the manufacturing stage. Natural color is grey. Impurities can include soil, bark, twigs, straw, leaves, etc. Their presence in the composition is acceptable at a level of 5%. However, craftsmen consider such a block to be of poor quality and do not provide a guarantee for the work;

chips exceeding the permissible limits in size. Such wood chips are not completely saturated with chemical compounds, which ultimately affects the strength of the block (the adhesion of wood chips and cement is impaired);

using sawdust or small wood chips. This is also unacceptable, since the proper reinforcing bond is not provided. A block made from small chips is initially fragile. The manufacturer is trying to increase its strength characteristics by increasing the amount of cement in the composition. However, such an arbolite block has a higher thermal conductivity coefficient;

the volume of voids between the chips should not exceed 3%, visually the block should look “tightly packed”;

try to buy wood concrete blocks from the manufacturer or its official representative in the region with the possibility of on-site testing (test testing of selected samples from the batch).

Having familiarized yourself with the pros and cons of wood concrete, as well as recommendations for relative choice, you can be confident in the correctness of the decision made to build a house from wood concrete blocks.

Arbolite Construction of a house

Do-it-yourself house made of wood concrete blocks - step-by-step instructions for building a cottage from wood concrete, from the foundation to the roof. Laying walls,…

House made of foam blocks - pros and cons, advantages and disadvantages, criticism, opinions, discussion. What are the benefits of foam concrete houses and what are the downsides...

Advantages and disadvantages of foam blocks (strength, density, weight, environmental friendliness, geometry), how to choose the right foam block, how to determine the quality...

Masonry (aerated concrete, foam concrete) on foam in cylinders, polyurethane glue. Pros and cons of adhesive foams, manufacturers, installation technology of aerated concrete,…

Log houses have been built in Russia for a long time. There are several construction technologies, and each has its own advantages and disadvantages...

Baths

Peculiarities

The best and uncompetitive material for a bathhouse is, of course, wood. Any other options are its substitutes, which lack some properties. Arbolit is no exception.

Wood concrete consists of 75% wood and due to this its qualities are to some extent close to the properties of wood. In any case, this material is clearly better than brick or ordinary concrete. The fact is that if the temperature in the home is maintained constant, then the bathhouse is a room where heating is expected as quickly as possible, but only periodically.

That’s why wood is the best material: it provides quick heating, good thermal insulation and at the same time removes excess moisture from the bathhouse to the outside. The walls in a wooden bathhouse never “cry”.

Wood concrete does not have the latter property. The wood chips in its composition are crushed to such a state that the difference in the direction of the fibers does not matter. Therefore, wood concrete should be considered not as an analogue of wood, but as a stone building material with high vapor permeability.

Wood concrete bathhouse (photo)

Sequencing

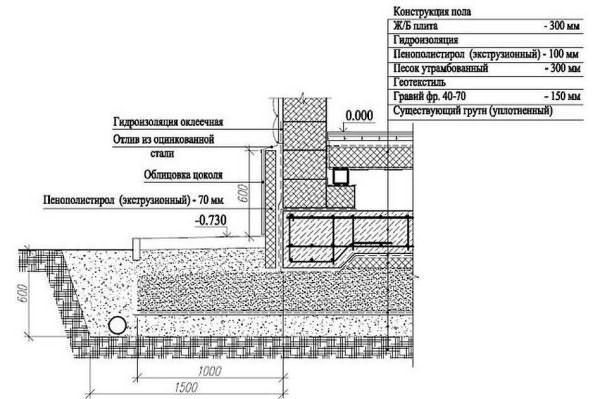

- The foundation for a bathhouse is usually made of a strip type, with a mandatory base of 50 cm above the ground.

- The masonry of the walls is the most common; for a bathhouse they suggest laying them in half a block, that is, laying the “brick” on an edge.

- But when finishing a bathhouse, a rather complex multi-layer “pie” is built. The point is that for both the home and the bathhouse it is important to observe the correct order of materials: its vapor permeability should increase from the inside to the outside.

- According to the characteristics, only wooden lining is suitable for external cladding.

The sequence of building a bathhouse from wood concrete with your own hands is as follows:

- Interior decoration with wood, in fact, there is already a violation here, since the vapor permeability of wood, of course, is higher, the ventilation gap is 1.5–2 cm, vapor barriers and insulation are basalt wool, since it is a non-combustible material.

- Then a wall made of wood concrete, a windproof film, again a ventilation gap of 2–5 cm and external finishing.

A lot depends on the quality of wood concrete, as numerous reviews from owners of bathhouses made of wood concrete on the forums state.

- If structural wood concrete with a high cement content is used for construction, then you cannot do without a vapor barrier and basalt insulation: the material’s properties are much closer to sawdust concrete, and such a bathhouse will take a long time to warm up.

- If thermal insulation with a large amount of wood chips is used, then the insulation layer can be omitted.

Compliance with fire safety rules in such a bathhouse is no different from a brick one, since wood concrete, unlike wood, is completely non-flammable.

Read below about how to make a garage from wood concrete with your own hands.

The owner of such a building will tell you about the features of building a bathhouse made of wood concrete in this video:

Basic principles of construction

Foundation

When building a bathhouse from wood concrete with your own hands, sometimes the base is made of an insulated slab equipped with stiffeners. The recommended thickness of such a slab is 3 cm. It is also necessary to provide insulation for the blind area. To prevent the foundation from getting wet, all liquid is drained from it through a drainage pipe. Both the features of the blind area and the use of the drainage system are taken into account when digging a pit.

Walls

The usual step-by-step instructions for building wood concrete baths often ignore the fact that they are built in the spring. More precisely, the professionals who compose such instructions forget this most obvious fact to them. If necessary, the blocks can be cut into the required parts using a circular saw. It is supplemented with a 33 cm disc. The openings must be strengthened.

Installation of windows and doors

For a bathhouse, it is recommended to choose wooden windows and doors. The thickness of the structure should be such that the dew point is inside the glass unit. If the required thickness exceeds 22 cm, you have to either increase the thermal protection or use triple glazing. Self-tapping screws and anchors in arbolite walls are almost always screwed in by hand. Tools are used only in isolated cases.

Be sure to evaluate the size of the opening and how it is located. If necessary, if the level shows the presence of excess, they are cut off and the surface will have to be sanded. That part of the block where chips are exposed that are not covered with a cement layer must be impregnated with a protective mixture. The best option for processing are natural oils.

The same applies when installing doors.

Plastering walls outside

In some cases, it is possible to finish only the seams with plaster, and leave the rest of the surface unfinished. In wet rooms, the entire volume is plastered. In dry rooms, all surfaces, except seams, are covered with clapboard. If plaster is nevertheless applied, careful preparation is not necessary - adhesion to the surface is ensured from the very beginning. But to extend the life of the structure, it is useful to use steel wire mesh.

Making the ceiling

The first thing to do is install the ceiling. The material must be treated with fire retardants. To fasten the beams, mounting plates made of selected metal are used.

Further:

- hemmed with boards;

- insulation is made with expanded clay or other material (most often basalt wool);

- form a vapor barrier;

- make hydraulic protection;

- install plank flooring.

Interior decoration

The material used to decorate the walls of the wood concrete bathhouse inside must be:

- strictly hygienic;

- perfectly tolerates heated air and contact with water;

- non-toxic;

- resistant to mechanical damage.

No insulation required. The steam barrier is installed only in the steam compartment. For its manufacture, foil material is used. A sheathing is placed above it with a gap for ventilation. The clapboard is already attached to this sheathing.

Finishing

As for finishing, there are no restrictions here. Materials can be selected to suit your taste. The only thing is that in regions with high humidity, it is better to treat the walls outside with waterproof material.

External

Finishing is so important for aesthetics, because a bathhouse made of untreated blocks looks ugly. In addition, the external design is also intended to protect the walls from moisture and other negative influences.

Experts recommend two preferred finishes for wood concrete baths: treating the surface with rough plaster, and then installing a ventilated façade; facing with lime mixture, as it has high vapor permeability.

Internal

Interior decoration may vary. The most important thing to consider when decorating is the moisture resistance of the material. Vapor barrier is installed only in the steam room. In some cases, only the seams can be sealed with plaster, and the rest of the surface can be left unfinished.

In damp rooms it is better to plaster. In dry rooms, all surfaces can be covered with boards. When applying plaster, surface preparation is not required, since adhesion to the surface is initially ensured.

We suggest you familiarize yourself with How to install a chimney stove in a bathhouse

You can build a bathhouse from wood concrete with your own hands. Using this favorite among many materials saves money, and any home craftsman can handle the job.

Construction of an arbolite bathhouse costs the same as a wooden structure. The only advantage is that in this case there are great possibilities for planning and finishing both outside and inside.

External

Finishing is so important for aesthetics, because a bathhouse made of untreated blocks looks ugly. In addition, the external design is also intended to protect the walls from moisture and other negative influences.

Internal

You can build a bathhouse from wood concrete with your own hands. Using this favorite among many materials saves money, and any home craftsman can handle the job.

Construction stages

When planning to build a house from wood concrete according to the chosen project, it is necessary to carefully study all stages of the construction process

Regardless of whether you plan to do everything yourself or with the involvement of specialists, it is important to familiarize yourself with general information about the main tasks

If a standard project is chosen, then it needs to be adapted to wood concrete. Almost any project is suitable for building a house from this material, you just need to finalize certain nuances.

What stages of work need to be worked out when adapting the project:

- Geodetic studies - check the depth of groundwater, choose the optimal type of foundation and determine other important points.

- Floors – wood concrete is strong enough to withstand both prefabricated reinforced concrete and wooden floors.

- Waterproofing must be made from materials suitable for wood concrete.

- Insulation is a frost-resistant material, so at this stage of work you can save money (not do it at all or to a minimum).

- Finishing is carried out using materials that are suitable for wood concrete and reliably protect it from negative influences.

Geodetic survey, selection or creation of a project. The choice of foundation is most often a strip or monolithic option. Wood concrete is lightweight and does not require a very strong base. Shallow tape will be an ideal choice and will reduce construction costs. If the groundwater lies high, it is better to make a columnar foundation or arrange a basement. Plinth - is installed above the foundation due to the fact that wood concrete is hygroscopic (absorbs water), the height of the plinth is 50 centimeters, it is well waterproofed. Wall masonry is made of wood concrete, with or without a frame. External walls are made from 30 centimeters thick, internal walls can be narrower. For masonry, special glue or cement mortar is used (but in this case, cold bridges may appear). During the laying process, the blocks are moistened with water or treated with moisture-retaining impregnation so that moisture from the solution is not absorbed into the material. If wood concrete is used as insulation, then it is placed between brick walls. Rafter system - can be of any configuration. But the edges of the roof should be 30-50 centimeters from the wall. Roof - an arbolite box can withstand any type of roof, so the roof can be made of slate, ceramic tiles, but the best choice is bituminous tiles

It is important to make the overhangs wide so that slanting rain cannot reach the wood concrete. Insulation – there is no need to insulate walls made of wood concrete, but it is advisable to conduct a heat audit of the house to find places where heat may be lost. Most often, heat is lost: in the floor due to its proximity to the ground (insulated with expanded clay or mineral wool), through the ceiling/roof (if there is a non-residential attic space, you need to insulate the ceiling, otherwise, insulate the roof), windows (all cracks are filled with polyurethane foam , seals or silicone sealants). Protecting walls from dampness is an important point that must be taken into account when performing exterior/interior decoration. Finishing work can be carried out immediately upon completion of construction, because wood concrete shows shrinkage at the level of 0.4%.

Exterior finishing usually involves plastering. The consumption of plaster when working with wood concrete can be one and a half to two times more in comparison with finishing a concrete wall. The layer will be smooth and durable even without the use of reinforcing mesh.

Suitable types of plaster for finishing a house made of wood concrete:

- Limestone – requires additional treatment (primer, putty).

- Cement – for a standard block, a layer 2 centimeters thick is enough.

- Decorative - compositions based on acrylic, lime, latex are suitable.

Sheathing is most often done with the installation of a ventilation gap in the form of a wooden sheathing.

Which exterior finish is suitable for wood concrete:

- Clapboard, block house, imitation timber - housing decorated with such materials looks like a wooden house.

- Facing brick - the house will be no different from a brick one.

- Vinyl siding - there are a huge number of options, the material is practical, non-flammable, and attaches well directly to the wall.

Interior finishing is most often carried out in the format of plastering or cladding with sheets of plasterboard on the frame. Then the walls can be covered with cardboard or painted.

It can be finished with clapboard, which is mounted on the sheathing, which acts as a ventilation gap and allows you to effectively hide all communications.

Monolithic wood concrete

The use of monolithic construction is another way to create a high-quality bathhouse made of wood concrete. Such construction of walls is carried out by pouring wood concrete mortar into the formwork, which recreates the outlines of the future shape of the wall. It can be assembled from plywood, wooden boards, metal sheets or polymer-coated wooden mesh.

In the case of wood concrete, the strength of the formwork may be less than compared to traditional concrete, since the density of the filled mass is much lower. Therefore, in some cases, a board one inch (25mm) thick is sufficient to make it. The main thing is compliance with the dimensions and strict verticality of the formwork in relation to the foundation.

As reinforcement, for additional structural rigidity, you can use a plank frame installed in increments of up to one and a half meters. This will create the necessary expansion joint and evenly distribute shrinkage loads when humidity changes. The reinforcement board should be pre-treated with a special compound that prevents rotting.

Arbolit pros and cons

Our time is characterized not only by an abundance of construction technologies, but also by a large selection of materials that can be used to build houses for permanent residence. Several decades ago, private developers had to make a choice between two materials. They chose between brick and wood. Depending on their financial capabilities, they purchased the most suitable material.

Given the current reality, the choice is incredibly huge. In addition to wood, developers can choose foam blocks or opt for aerated concrete. In addition, houses can also be built from expanded clay-based materials.

Recently, a material such as wood concrete has begun to gain popularity. We will consider the pros and cons of this material.

Arbolit composition

Advantages of wood concrete

So, wood concrete, also known as sawdust concrete (chip concrete) or wood concrete. Blocks made from it are inexpensive and at the same time have a wide range of performance characteristics. Many people who want to build an eco-friendly home choose this material. Despite the fact that wood concrete blocks mostly consist of wood chips, they nevertheless delight with their reliability and durability.

Textured wood concrete

The properties of this material largely determine the situation where many developers give preference to it. By building a house from this material, you can get a reliable structure that will not have any impact on health and will not be expensive. Many people do not like the gray appearance of such buildings. However, this problem can be easily solved if the finishing work of the facade walls is carried out using modern materials, which are offered in a wide range in construction stores.

Textured wood concrete

It is necessary to understand that none of the building materials currently offered is without drawbacks. Although wood concrete blocks have many advantages, this unique material also has disadvantages. If you are seriously considering wood concrete as a material for building your new home, then, of course, you should learn about the main disadvantages of this material.

Disadvantages of wood concrete. Disadvantages of the material

One of its main disadvantages is that it does not tolerate moisture. Therefore, when constructing a structure, the walls of rooms in which high humidity will be present must be made of another more moisture-resistant material, but not wood concrete.

The thing is that this material is made from wood chips, and everyone knows that wood does not tolerate moisture well. Therefore, it is worth abandoning the idea of using this material in rooms with high humidity. If you neglect this recommendation and, for example, make walls from this material in the bathroom, then you will encounter certain problems. The material will absorb moisture, and ultimately this will lead to its performance characteristics being noticeably reduced. As a result, the service life of the structure will be significantly reduced.

However, we note that it is possible to eliminate this drawback. To do this, you can finish walls made of arbolite blocks using modern finishing materials. An excellent option would be to use plaster.

Another disadvantage that you should be aware of is that wood concrete blocks have poor resistance to gases with an aggressive environment.

In addition, this building material has other disadvantages. The basement of the house, which is built from arbolite blocks, must be additionally finished. The main goal of this work is to achieve maximum dryness. In this case, you can ensure a long service life of the structure.

We should not forget that arbolite blocks are 90% wood. For this reason, it is necessary to regularly monitor the condition of the base. In winter, it is necessary to regularly inspect it and ensure effective drainage of water, and also ensure that there is no snow near the base.

Another disadvantage of the material is that such blocks do not have ideal geometry. However, we note that this drawback does not have any effect on the speed of construction work. But it is still necessary when doing masonry to make a choice in favor of a mortar based on cement and sand. In this case, the unevenness of the blocks used during construction will be leveled out due to the mortar.

This is interesting: Construction of a house from arbolite blocks

Arbolite bathhouse: technologies, materials, proportions + video and photo report

Choosing a building material for a bathhouse is not easy. It is necessary that it retains heat well, a high degree of vapor conductivity is desirable, and at the same time it should not accumulate moisture. I also want it to be natural and easy to use. Oddly enough, such material exists, and it is relatively inexpensive - a bathhouse made of wood concrete is considered a budget building. At the same time, the performance characteristics of the material are more than good.

Finishing inside and outside - any

What is wood concrete and its types

Wood concrete is one of the varieties of lightweight concrete, the filler of which is wood chips and/or other crushed organic aggregates. The binder is high-quality cement of a grade not lower than M400, but better than M500.

All characteristics of wood concrete, the requirements for it, are described in GOST 19222-84 and SN 549-82, the production technology is described in detail in the book by I. Kh. Nanazashvili “Arbolite - an effective building material.”

There is another building material based on wood waste - sawdust concrete. It is often confused with wood concrete. But this is a completely different building material, with different characteristics and qualities, and has a different composition (you can use sawdust rather than wood chips, and sand is also present as part of the filler).

Types of wood concrete and its application

Depending on the density, sawdust concrete can be:

- structural density from 500 kg/m3 to 800 kg/m3;

- thermal insulation - its density is up to 500 kg/m3.

Like any type of concrete building blocks, wood concrete blocks are graded for density and strength. The most popular brands and their main characteristics are shown in the table below.

Wood concrete strength grades and scope of application

For the construction of houses of 1.5 floors and above, wood concrete with a density of at least 600 kg/m3 is used. For one-story baths under a light roof, you can use a density of 500 kg/m3.

Also, for the construction of baths, an important characteristic of a building material is thermal conductivity. In this sense, wood concrete has very good indicators: it has even better indicators than aerated concrete and foam concrete. Can also be used as insulation.

Thermal conductivity, as is known, depends on density: the denser the block, the better it conducts heat (see table).

Thermal conductivity of wood concrete of different densities

Another important point when building baths is water absorption and hygroscopicity. Here it is worth understanding that these are two different characteristics. Water absorption (moisture absorption) is the ability of a material to absorb water (in a liquid state). If you place a wood concrete block in water, it can absorb 40-80% of its mass.

Hygroscopicity is the ability of a material to absorb vaporous moisture from the environment. So, the hygroscopicity of wood concrete is assessed as “very low”. That is, it does not accumulate steam in itself.

If we translate this into practical terms, this means approximately the following: if you protect the wood concrete from direct contact with water, there will be no problems with humidity in the building. This means that there must be good waterproofing of the foundation and the facade must be protected from precipitation - external finishing must be done. Any finishing is suitable - from plaster to cladding with any material.

Comparison of building materials by thermal conductivity

In practice, many wood concrete baths stand without finishing the outer walls for years - 5-7 years - and no problems with moisture or damage to the integrity of the blocks are observed. But this is subject to the use of high-quality blocks of the declared density and strength.

Composition of wood concrete and materials for it

As already mentioned, the binder in wood concrete is cement, and the filler is wood chips or other organic fillers. But the flail is very poorly coated with cement paste and, as a result, the strength of the material is low. To improve adhesion, chemical additives are needed - they are also a necessary component. And the fourth component is water. Now for each component in more detail.

Wood concrete composition

Aggregate

The filler for sawdust concrete can be various organic components:

- Sawdust or chips of coniferous species - spruce, pine, fir. These breeds are the best. When using larch chips, the amount of chemical additives doubles.

- Hardwood sawdust - birch, beech, aspen, poplar.

- Bonfire hemp, flax.

- Cotton stalks, rice straw.

All these components must be broken down into fragments of a certain size. The brome and stems are cut into fragments no longer than 40 mm. In this raw material, the admixture of tow and tow should not exceed 5%. The presence of rot or mold, the presence of pieces or fragments of clay, soil, sand, etc. must not be allowed. In winter, there should be no snow or ice in the raw materials.

The best filler is crushed wood waste. The wood is crushed into small pointed fragments no larger than 40*10*50 mm. The optimal size with which the strongest blocks are obtained was established experimentally: length 25 mm, thickness 3-5 mm.

Wood concrete chips must have certain dimensions

Such chips can be obtained by crushing technological chips (they are wider) using hammer mills or crushers. Waste can be processed using chippers that have the ability to adjust the size of the chips (not all models). The best wood chips for wood concrete are obtained from rotary knife crushers and shredders. But this equipment is expensive and is not suitable for private use - only for production.

Wood shavings rarely meet these criteria. The only more or less suitable option is waste from calibrating machines, and then those that are specially configured and the waste has a thickness of no more than 4-5 mm (usually the chips are thicker).

Cement

The binder for wood concrete must be high-grade. According to GOST recommendations, the following can be used:

- quick-hardening and ordinary Portland cement;

- Portland cement white or colored;

- sulfate-resistant cement.

The cement must be of good quality

Brand - not lower than M500. According to the recommendations of the standard, it is permissible to use M 400, but it is worth remembering that in fact the brand is 40-50 units lower than declared. This must be taken into account when drawing up proportions (increase the amount of cement).

Chemical additives

As already mentioned, special components are needed to improve the adhesion of cement and wood chips. The same GOST recommends:

- liquid glass;

- calcium chloride;

- alumina sulfate;

- lime.

Most often, liquid glass and lime are used, a popular combination of calcium chloride and liquid glass (in equal parts), as well as a combination of alumina and lime (also 1:1). The total amount of chemical additives is within 2-4% of the volume. Before use, the additives are diluted in water, stirred and added in this form to the mixture of sawdust and cement. Once again: additives are introduced only in a solution state.

One of the most popular supplements

Water

The composition of the water can be any that can be used for drinking - tap water, from wells, boreholes, even rivers and lakes. The main requirements are for temperature. As is known, for the normal hardening process, cement requires a temperature of +20°C. And the water must be filled with warm water, with a temperature not lower than +15°C. It’s up to you to decide how to solve the problem—heat it up or dial it in advance to warm it up, but you shouldn’t pour in cold water, otherwise the wood concrete will not gain the required strength.

Wood concrete proportions

If you decide to prepare wood concrete blocks yourself or build walls from a monolith, you will need proportions. They are given in tables, only the exact ratio is determined on the spot experimentally.

Arbolite proportions depending on strength class

Components required for the production of 1 cube of wood concrete, depending on the brand

Fine aggregate requires more cement and the amount of water depends on the moisture content of the same aggregate. So, when receiving a new batch of woodchips/sawdust, you have to adjust the proportions in one direction or another.

It is worth mentioning that forced-type concrete mixers are used in production, since gravity mixers do not mix the mixture well. However, people also work with traditional forced mixers, it is simply desirable that the inclination of the pear be adjusted within a wide range: moisten the sawdust with water, turning the pear almost “lying”, then pour cement into the wet ones and knead for another 5 minutes. After kneading, the composition must be laid in 15 -20 minutes, otherwise it loses its plasticity.

Arbolite construction technologies

Actually, there are two technologies: from ready-made blocks with brick-type masonry and monolithic walls. But monolithic technology has two varieties: you can cast walls from wood concrete of structural density without a frame, or you can assemble a frame (wooden or metal), and fill the gaps between the posts with wood concrete, but of a lower density with better thermal insulation characteristics.

If we approach it from the point of view of reliability, then monolithic technologies are better - they do not have cold bridges and there are no problems with seams. If we talk about cost, then the price of arbomonolith is not as low as many people think. The main snag is mainly in the “extraction” of wood concrete chips. Even if you find a source, the price will most likely not be very low. Next are the costs of hired workers. It is possible to do it with one hand, but it is very difficult: the process is highly labor intensive:

- bring sawdust, cement;

- knead;

- unload the solution into the cart;

- deliver to the place of installation;

- pour into formwork;

- compact;

And then - first. On the scale of a small bathhouse, one person can handle it, but it will be very difficult physically, and construction will progress slowly. If you require high or medium speed, you must have two or more assistants. If the assistants are hired, they will have to be paid. As a result, the cost per cubic meter of laid wood concrete, even with your active participation, will be almost the same as when laying blocks (sometimes even more, depending on the amount of payment). So decide for yourself.

Construction of a bathhouse from wood concrete in photo

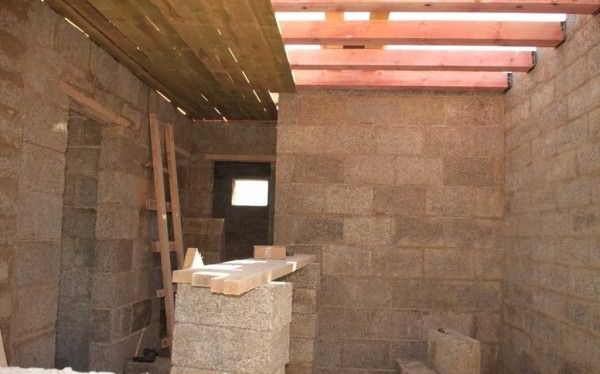

Wood concrete for the bath was chosen after much thought and study of different materials. I liked the combination of low thermal conductivity and good vapor permeability in this material. That is, heating with the correct wall thickness will require little time and there will be no problems maintaining normal humidity. The naturalness of the material also played an important role - almost all components are of organic origin (with the exception of a small amount of chemical additives). This is an important factor for baths and homes.

First, we decided to build a bathhouse-guest house, gain experience, and then start building a house (also made of wood concrete). The bathhouse has a 6*8 plan, a metal roof, an attic without insulation.

Layout of a bathhouse made of wood concrete

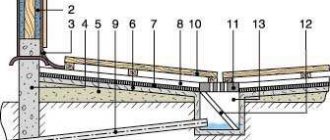

The foundation chosen for the bathhouse is an insulated monolithic slab with stiffeners. The thickness of the slab is 30 mm; an insulated blind area is also planned. To drain groundwater, a drainage pipe is laid around the perimeter.

Sectional view of the foundation for a bathhouse made of wood concrete

The strength of this foundation is clearly excessive, but we do not exclude the possibility that we will later want to complete the second floor.

A pit was dug under the foundation, taking into account the blind area and the installation of a drainage system. All layers are laid according to the scheme, everything is compacted layer by layer, formwork is installed, two reinforcement belts are connected.

The foundation is ready to be poured

When installing a slab, it is important not to forget about communications - lay pipes for sewerage, electrical input, etc. Concrete was ordered at the factory, as a large volume is required at once. Even during the pouring process, we process the concrete with a submersible vibrator. It “sits down” right before your eyes, becomes more fluid, filling all the voids.

Processing concrete with a vibrator

After pouring, there is almost no need to even level the surface. From vibration it is almost mirror-like. Cover with film. leave it.

In a couple of days, wood concrete blocks are delivered. The game is good - all the edges are even, there is almost no fighting. We unload them next to the foundation. We cover the blocks and foundation and leave them to winter.

These are wood concrete blocks

Cover and leave for the winter

We begin construction in the spring. The walls are erected quickly - the blocks are large, the geometry is normal. If necessary, the blocks were sawed with a circular saw with a 330 mm disc.

The process of constructing walls from wood concrete

The box is ready

The openings are secured

The outside walls were not plastered, only the seams were plastered. Some rooms - wet - were completely plastered; in dry ones, the seams were also only plastered, and then the lining was filled.

We begin the installation of the overlap. First, we treated all the lumber with fire retardants. The beams were attached to metal mounting plates.

Beams were attached to mounting plates

Then they hemmed it with a board.

Beam system top view

A vapor barrier (overlapping, taped), basalt wool 150 mm thick (100+50), waterproofing (vapor-permeable membrane) is laid on the backing. From above, all this is covered with a flooring made of boards. You can install a roof.

Flooring on top

The roof is gable, the attic is cold. The rafters were fastened with nails, the joints were reinforced with corners and mounting plates.

Rafter system

Nodes are closer

Next, the sheathing was filled, a windproof membrane was laid, and then metal tiles were laid.

The sheathing is ready

All that remains is to install the wind board, make ebbs and decorate the overhangs

The base was covered with polystyrene foam. Next is a series of walls. The perimeter was sheathed with wind protection - Isoplat 12 mm thick.

The base was first coated with bitumen mastic, then polystyrene foam was secured

The walls were sheathed with wind protection

Next is the sheathing and siding along it. At first I wanted a block house, but its regular maintenance is not pleasing.

Lathing and siding

This is what a wood concrete bath looks like with exterior finishing

Based on the results of use, we can say that the material is really good. And it’s convenient to attach to it, without problems, and warm. In the summer the house (until we build the house we will use it as a living room) is cool, in the winter it maintains the temperature very well. With the standard finishing of the steam room, the steam holds well, but the stove is not bad either (Feringer).

The blocks left after construction are simply lying in stacks, uncovered (almost 2 years already). There are no visible changes.

Video on the topic

baniwood.ru>

Advantages and disadvantages

Due to its structure and characteristics, wood concrete (wood concrete) is endowed with both a number of positive qualities and some flaws.

In general, there cannot be a building material consisting of only advantages, otherwise it would be used everywhere, and the rest would be undeservedly forgotten. The advantages of wood concrete as a building material are obvious.

Thus, a block made of wood concrete has many advantages.

The disadvantages of wood concrete blocks include some nuances.

The manufacturer's ability to profit from the cement used in the production of blocks. In this case, the building material sharply loses its strength, thus, this minus eliminates some of the previously presented advantages. Similarly, a disadvantage that can nullify a number of advantages is the permissibility of changes by the manufacturer in the fraction of wood particles in the structure. It follows from this that it is likely that products will be produced with too large a fraction of wood chips or, on the contrary, the main share of the wood component may be sawdust

Both options have a great influence on the quality characteristics of the finished block and, consequently, the structure built from it. Wood concrete, due to the wood in its structure, is capable of absorbing water in significant volumes, which is why close attention must be paid to protecting wood concrete structures from water penetration. Another drawback is the frequent errors in the geometry of wood-concrete blocks; they, as a rule, are not very strong, but can lead to excessive consumption of masonry cement mortar. And it increases the thermal conductivity of the rebuilt wall, which is also difficult to call an advantage.

Having analyzed all the advantages and disadvantages of wood-concrete blocks, we can draw the appropriate conclusions.

Building materials should be used with caution for buildings with a high level of air humidity inside. Before purchasing, it is imperative to check the material and make sure of its quality characteristics.

It is necessary to evaluate the size and interweaving of wood particles located in the structure, check the absence of excessive formation of hardened cement mortar or components of products that are not tightly coupled to each other

Before purchasing, it is imperative to check the material and make sure of its quality characteristics. It is necessary to evaluate the size and interweaving of wood particles located in the structure, to check the absence of excessive formation of hardened cement mortar or components of products that are not tightly coupled with each other.

Arbolite bathhouse as an alternative to a wooden frame

To build a bathhouse in a garden plot, commonly available natural building materials are used. The most widely used materials at present are burnt bricks and natural wood in the form of rounded logs or wooden beams. However, recently a relatively new building material called wood concrete has appeared on the market for products for individual development.

Construction of a bathhouse from wood concrete.

Advantages and disadvantages of wood concrete

In this article we will try to understand what wood concrete is, what it is made of, and what it is used for. Find out its main properties and characteristics, similarities and differences in relation to other building materials, identify its positive and negative aspects. And finally, understand how reliable and efficient wood concrete baths are, and whether it is advisable to use this material for private construction (find out here how to make a sauna stove from a metal pipe or brick).

Blocks drying after production.

What is wood concrete

Arbolite is a building block made of lightweight concrete. It uses Portland cement M500 as a binder, and organic materials in the form of wood shavings, wood chips, sawdust, waste from hemp and flax production are used as filler.

In addition, it also contains various auxiliary substances, the action of which is aimed at increasing the strength, durability and water resistance of this material, for example, slaked lime, an aqueous solution of liquid glass, mineralizing additives, etc.

The wood filler is kept in the open air for a long time (several months), and then, before being added to the solution, it is subjected to chemical and antiseptic treatment. This is done in order to prevent the oxidation of sugars and the decomposition of organic substances that make up wood and plant fibers.

Plastered surface on the front side of the block.

The prepared solution is poured into molds in several layers, compacted using vibrators, and after hardening and drying, a building block is formed, completely ready for use. The technological instructions recommend the standard dimensions of such a block are 600x300x240 mm, however, other options are possible.

The weight of a wood concrete block is significantly less than the weight of an equivalent concrete block, which makes it possible to build a bathhouse with your own hands without much difficulty.

Wood concrete block.

Wood concrete versus brick

In order to understand how appropriate it is to use wood concrete for the construction of a bathhouse, we present some comparative characteristics of this material with the properties of baked brick.

- Mechanical strength. According to this indicator, brick, as a monolithic material, occupies a leading position, but the wood concrete block is only slightly inferior to it.

- Resistance against pests, rot and mold. Brick is still in first place, since its dense structure and lack of organic matter completely excludes the development of microorganisms and its consumption by rodents. However, in a wood-concrete block, all organic particles are enclosed in a concrete shell, which also makes it inaccessible to pests and destructive microorganisms (see also the article “Fungus in the bathhouse - folk and modern methods of control”).

- Moisture resistance. Neither material loses its strength in conditions of high humidity, however, they should still avoid constant contact with water.

- Thermal insulating properties. This indicator is very important for a bathhouse, and the wood concrete block, due to its porous structure and low thermal conductivity of the filler, is a much better thermal insulator than brick.

- Fire safety is also an important characteristic of bathhouse material. Brick, of course, occupies a leading position, however, a wood-concrete block can withstand exposure to an open flame for 1.5 hours, without loss of mechanical strength.

- Moisture and vapor permeability, or ventilating property, is the ability of a material to conduct through itself and remove excess moisture from the room. Thanks to the organic base with a capillary structure, the wood concrete block can freely pass moisture through itself and evaporate it out.

Making blocks.

Advice! To prevent open water from entering the wall or roof slopes, it is recommended to extend at least 0.5 m beyond the outer dimension of the wall.

Properties and advantages of wood concrete

Having considered this problem, experts came to the conclusion that the best solution to such shortcomings would be to use other materials for the construction of walls. And such material was invented back in the distant 50s of the twentieth century. It consists of crushed wood chips used as a base and a cement mixture, which serves as a fastening agent. The material was given the name Arbolit. Depending on the proportions of the components, blocks made from it acquire strength comparable to foam concrete or shell rocks, but at the same time have a number of advantages. If mineral reinforcing components were also used in manufacturing, the material acquires additional resistance to destruction.

- Firstly, due to the high content of wood in the blocks, houses built from wood concrete are distinguished by excellent sound insulation. Moreover, the walls acquire this property even without finishing. When the house is plastered and interior finishing work is done, the soundproofing properties increase further.

- Secondly, the wood contained in the walls perfectly retains heat inside the house and prevents the penetration of cold from outside. With a wall made of wood concrete having a thickness of 30 cm, the thermal protection is comparable to walls made of brick and having a thickness of at least one meter.

Along with the positive aspects, the wood content also introduces certain restrictions. In particular, the outer part of the walls must be plastered and insulated, since due to their structure the blocks have increased airflow and absorb a lot of moisture. Otherwise, reviews about a house made of wood concrete, people living in cold regions, are inclined to the idea of building their homes from this material.

Most owners of houses built from wood blocks have chosen this particular material due to not only its thermal protection and sound insulation, but also its environmental friendliness. In the process of making briquettes, no substances that can harm human health are used, and this is a fundamental factor for many.

In addition, it is also important that, despite the high wood content, the blocks are absolutely fireproof. If a wood block is thrown into a fire, it will not catch fire, even after lying in the fire for about half an hour, which means that a wall made of it resists fire in the same way as brick or other similar materials

Another question that initially worries future owners of wood concrete homes is how susceptible the walls are to attacks by insects and other parasites that usually live in wood. To dispel fears, it is enough to say that wood-concrete is classified by experts into group 5 in terms of biostability. This means that thanks to special treatment, the appearance of any microorganisms inside the walls is completely excluded. Not only insects do not grow in the walls, but also mold or any other fungal microorganisms.

This is interesting: How to plaster walls with gypsum plaster

Making molds for wood concrete blocks

If you are planning to build a bathhouse with your own hands, then you can make the blocks yourself. For this you will need: a concrete mixer, wood chips or sawdust up to five millimeters thick and no more than twenty-five millimeters long, grade 400 or 500 cement, liquid glass, water and molds for blocks. You should also make sure that you have a chemical reagent to neutralize the sugar contained in the wood. Typically, calcium chloride or aluminum sulfate are used for these purposes.

If it is not possible to obtain the specified reagents, it is recommended to keep the wood filler in the open air for three or four months.

Before the actual production of wood concrete, crushed wood pulp should be added to water, mixed thoroughly and kept in lime mortar for about three hours. This will completely neutralize the remaining sugar in the wood. Then the prepared mass is mixed with cement until smooth.

You can make your own molds from wooden boxes with a removable bottom. If you are planning a more serious production, the molds can be welded from sheet metal. Experienced experts advise covering the inner walls with linoleum, thick plastic film or other similar material to make it easier to remove finished products. When the required number of wood concrete blocks is ready, you can begin building the foundation.

The construction of a bathhouse is always accompanied by a search for suitable building materials for the walls and foundation. You can, of course, build a frame from oak timber, but in this case a wooden bathhouse will cost the same as a small one-story house. Building a bathhouse is no more difficult than building a house or garage, but it is important not to go wrong with the materials for construction. Therefore, it is better to build a bathhouse from materials for which there are reliable reviews about their quality and practical application.

This is the first question to which you have to look for an answer when calculating estimates and clarifying the costs of a future bathhouse. Not every material is suitable for building a bathhouse; I would not want to spend already limited funds on absolutely unsuccessful and unsuitable building materials.

You can build a bathhouse relatively inexpensively if you use affordable materials, the options of which, oddly enough, are not many:

- Wooden pressed plate;

- Red clay brick;

- Cinder block or expanded clay foam blocks;

- Foam concrete blocks;

- Arbolite blocks;

For your information! Casting walls in formwork from concrete mixtures, natural stone, rubble, gypsum stone, everyone's favorite sand-lime brick - all these reliable and durable materials are not suitable.

They are cold as ice, and do not get along well with hot water vapor.

An exception to the above list may be gas-filled foam concrete material, but such material has a small flaw, which is worth talking about below.