What types of stainless steel bath tanks are there and how to install them

An integral attribute of any bathhouse is the provision of cold and hot water.

In the case of cold water, you can install a centralized water supply, but hot water needs to be heated directly in the bathhouse in a special tank. We will tell you later in the material which water container for the bathhouse is best to use for heating water, and how it can be installed. Of course, in a homemade bathhouse you can install gas or electric equipment for heating water, however, in the conditions of a summer cottage, unexpected troubles may arise that will hopelessly ruin your vacation, because it will not be possible to quickly fix the breakdowns.

There may be several options for materials used in a bath, and each of them has its own pros and cons.

Cast iron boilers have long been used in village baths, so they have stood the test of time.

The advantages of such containers:

- They are not subject to rust, so the water in them always remains clean and suitable for use.

- Cast iron does not conduct heat well, so the water in such a boiler stays hot for a very long time.

But among the disadvantages we can name the following points:

- Cast iron has a very high specific gravity, therefore such a boiler will be very heavy and will require the construction of a very strong base. In addition, it will be very difficult to install it yourself.

- Due to the advent of lighter and more accessible materials, cast iron products are now almost never produced, so purchasing such a boiler can be almost impossible.

- You will have to spend a lot of money to purchase a cast iron boiler.

What is the design

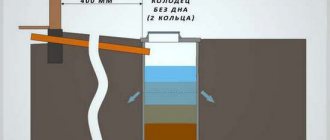

- Initially, a tank for heating water in a bathhouse was equipped with a heat exchanger - the design is quite simple. A special heating metal tank with a capacity of no more than 5 liters is built into the heart of the furnace, the firebox, or in an area with high temperatures. Which in turn is connected by pipes to the main tank in the next room; the tank can reach a volume of 120 liters.

Important: water must be poured into the system before using the sauna stove, otherwise if the stove is lit and water is then added, the water in the pipes may instantly boil and, as a result of a steam shock, the system will simply burst.

- The principle of operation is that from a large tank to a small one, cold water flows through the drive pipe, is heated in the small tank, which is called a heat exchanger, and returns through the outlet pipe to the main tank, already heated.

- If the drive and outlet pipes are positioned at the correct angle, then the water will successfully circulate by gravity thanks to natural physical laws. But in order to avoid the formation of air pockets in the system and ensure faster and more uniform heating of the water, the tank for the heat exchanger in the bathhouse is equipped with an electric pump for forced circulation of liquid in the system.

- The heat exchanger can be located directly next to the firebox itself, in which case it is installed at the stage of construction of the furnace inside the structure. Or it may have the so-called samovar operating principle, when a small tank is mounted around a metal chimney for a bathhouse directly next to the firebox.

- But regardless of the location of the tank, professionals prefer systems in which the liquid circulates freely, without additional pressure.

Schematic diagram of a samovar-type system.

Tanks in the bathhouse: features, types and correct installation

Since ancient times, the bathhouse in Rus' was valued much more than just a special place for cleansing the body. It was a whole ritual that was associated with the complete liberation of a person from excess spiritually and physically. It was largely thanks to the bathhouse with a birch broom that Rus' was famous for its red maidens and heroes. The bathhouse helped the Slavs to be healthy and strong, protected them from many diseases, and invigorated the body and spirit.

The popularity of bath procedures is not falling, it is only increasing every year. And this applies to the whole world. After all, the person who visited the bathhouse absorbs all the healing and health-improving power of the steam, and leaves from there in a great mood and rejuvenated.

What is a bathhouse without normal hot water? And to heat it, you don’t need a boiler at all, since there is a stove and a full-fledged fire in the stove. Well, the water will be heated through a special heat exchanger.

However, first you need to determine which tank for the bath will be better: remote, built-in or on a pipe, and what material it will be made of. In general, what exactly should it be so that at the time of using the bathhouse it definitely does not have to be changed to another tank.

You can, of course, find sauna stoves with a tank, but what to do when there is a stove, but no special container for heating? In this case, you can find special tanks for baths on the market or make them yourself, using a completely ordinary welding machine.

The water tank is a special welded structure, which is made from modern materials, equipped with an inlet for cold water and shut-off valves for hot water.

To choose the right tank for your bath, you should decide on the main parameters of the heater:

- type;

- material of manufacture;

- volume;

- installation method.

First, you need to provide for the principle of water intake, choose the appropriate size and installation method of the tank, so that in the future you do not spend an additional amount on re-equipping the equipment. The thickness of the walls of the structure depends on the size of the tank, which can range from 1 to 1.5 mm.

Next, you need to choose a method of heating the water - a stove or a built-in heating element. To decide which container will be more profitable to install, you need to take into account the total number of visitors for whom the bathhouse is designed.

If the bathhouse can accommodate no more than 2 people, then a device with a capacity of 50 liters is sufficient. For large companies, it is preferable to choose a tank with a capacity of 100 liters or more.

The material of manufacture and design features of the device should be taken into account when purchasing.

There are three types of water tank - built-in, remote or on a pipe. Moreover, each has positive and negative sides.

A built-in tank is a classic version of the design, installed on the bottom of a heating stove and combined at the top with the combustion chamber.

This ensures accelerated heating and maintenance of optimal water temperature for a long time.

In this case, the bottom of the tank is in direct contact with an open fire, and liquid is drawn from the tank from above or through a built-in tap.

A remote tank is provided for a furnace equipped with a heat exchanger. Such a device is connected to a heat exchanger using copper pipes, so it can be installed in any room of the bathhouse - washing room or dressing room.

Among the advantages of a remote-type water tank are maintaining a high water heating temperature, reliability and practicality.

The principle of operation of the device is quite simple: cold water enters the heat exchanger, and the heated liquid is supplied back to the tank.

The design of the tank mounted on a pipe is quite relevant when the bathhouse is used throughout the day.

Such a device provides rapid heating of water to a comfortable temperature thanks to the thermal energy released through the chimney pipe.

The tank on a bath pipe is distinguished by its significant dimensions, high thermal capacity and efficiency. In addition, it is able to prevent carbon monoxide leakage during frequent firing of the sauna stove.

The most common version of the device is a samovar-type tank, equipped with a single or double fitting. These tanks vary in volume, size and design.

Steel, cast iron or stainless steel?

Stainless steel water tanks for baths can be a worthy alternative to expensive and heavy cast iron.

The advantages of stainless steel are:

- It is not subject to corrosion, which is why it got its name.

- Allows you to make an object of any shape and complexity. Therefore, from the huge assortment of commercially available products, you can choose the most suitable stainless steel bath tank for you.

- Variety of product designs. If desired, you can install a hanging tank in the bathhouse above the heater, place it near the firebox, or place it on the chimney pipe.

- The low cost of the material makes it accessible to a wide range of consumers.

A lot depends on the building material from which the tank was made - both the durability of the tank itself and the rate of heating and cooling of the water in it.

For a long time, the tank in the bathhouse was made exclusively of heavy cast iron - the water in it took a long time to heat up, and quite a lot of firewood was consumed, but the hot water was available until the evening and the whole family could wash all day. In addition, cast iron is not afraid of either high temperatures or corrosion. But its big drawback, of course, is obvious.

However, today stainless steel sauna tanks are becoming increasingly popular. There is no need to isolate moisture from it, its thermal conductivity is simply excellent, and the deformation rate due to very sharp temperature fluctuations is extremely small and cannot be compared with the qualities of ferrous metals.

The best brands for these tanks are 08X17 (430) and 8-12X18H10 (304), which are also used to create dishes. They are absolutely resistant to extreme temperatures, completely hygienic and cannot be deformed or corroded.

Such tanks are made for a bath from thin and durable stainless steel sheets, where special ball valves are installed to supply water. Caring for these tanks is extremely easy. Therefore, if you definitely do not want to spend your time on caring for water tanks in the bathhouse, feel free to choose this variety.

We suggest you familiarize yourself with Floor screed on a concrete base

Enameled tanks will completely save you from unpleasant rust. Their only drawback is possible chips, which can lead to corrosion. True, they can always be treated with special heat-resistant paint - if the tank itself is not inserted into the oven.

Heating circuit: from a stove or heating element?

Whether it is more profitable to heat a stove in order to heat the water or whether a heating element is much more effective in this regard depends only on exactly how many people in the future will simultaneously steam in the bathhouse and how quickly they will need hot water for washing. For example, a capacity of approximately 50 liters is sufficient for one person, and at least 70 liters for the whole company.

The ability of the tank to warm up quickly enough also depends on its walls - the thicker they are, the longer it will take to warm up and the more it will weigh. For a sauna tank with a volume of up to 50 liters this is 0.8-1 mm, for a larger one the walls are definitely not thinner than 1.5 mm.

Materials for making tanks

The type of material used to make the sauna tank determines the durability and reliability of the structure, the speed of heating and cooling of the liquid. Water heating devices are made of stainless steel, cast iron and metal.

The most popular material for the manufacture of tanks for heating water in a bathhouse is stainless steel. It is resistant to corrosion, fire, high humidity, deformation and damage.

In addition, stainless steel products have high thermal conductivity, hygiene and resistance to temperature changes.

The stainless steel tank can be presented in cylindrical and rectangular shape.

Proper care of stainless steel products guarantees efficient operation and a long service life.

Made of cast iron

Cast iron remains the traditional material for making water tanks. It has good performance characteristics - low thermal conductivity, resistance to corrosion, deformation, mold and overheating.

The disadvantages of cast iron products include their impressive weight and complexity of installation.

In cast iron tanks, water heats up slowly, but also cools down over a long period of time. Therefore, one volume is enough to satisfy hot water needs for the whole day.

Made of metal

The cheapest option is metal tanks, which are susceptible to corrosion, rotting and deformation. Such characteristics can negatively affect the quality of water and the durability of the product.

It is strictly forbidden to paint metal devices with moisture-resistant paint, which can release toxic substances when heated.

Less popular are enameled tanks, which are sensitive to mechanical damage. If there are chips in the enamel, such devices are not recommended. To protect the heaters from possible corrosion, their surface is treated with a special heat-resistant compound.

Stainless steel tanks of the remote type are considered the most practical and reliable. Such designs are distinguished by their attractive appearance and safe operation.

Quite a few experienced bath attendants recommend making containers from stainless steel. Most of its advantages were listed above and all of them indicate great convenience in using such material. But it’s worth considering that there are different grades of stainless steel, and not all of them are suitable for making a container with water in a bathhouse.

Craftsmen often use a stainless steel pipe. In this case, the container looks like a barrel. And this is a rather convenient option, because you don’t have to spend a lot of time calculating the size and connecting the sheets. To make such an iron barrel, you must complete the following steps:

- First you need to cut the required piece of pipe with a grinder.

- The cut areas of the pipe must be carefully processed. You can use a regular file for this. A drill with special attachments will help make the task easier and save a lot of time.

- Then you need to start installing the bottom and top lid of the container. Actually, for this you need to find a sheet of stainless steel. Typically the thickness of the top and bottom parts is greater than the walls of the tank itself. On the sheet you need to draw an even circle in accordance with the diameter of the pipe. The necessary circles are cut out and processed again. If a stove pipe will pass through the container, then additional holes are made in the lower and upper parts in accordance with the diameter of the pipe from the stove.

- The next stage of work is connecting the cut out parts with the main part of the future container. For this, a welding machine or soldering method is used (which is much more difficult and time-consuming). After joining, again you need to carefully process the welding seams. By the way, if necessary, and for convenience, it is not at all necessary to weld the upper part. It can be secured to the body with bolts or made in the form of a cover so that it can be removed. This is done when the container is not connected to the water supply and water is filled in manually.

- The next stage of work is the most painstaking. A tap and pipes must be installed on the container. To do this, the stainless steel needs to be drilled from the bottom and top in the places where the taps will be located. Sometimes the pipes are simply welded to the container so as not to make a special thread.

- Then work is carried out to install the container. They are described in more detail below.

Stainless steel tanks are actively used in baths, steam rooms, and saunas. We create high-quality tanks that will last for a long time. At the same time, we offer clients an individual approach, the opportunity to create products of any size.

The use of stainless steel tanks

A stainless steel tank is used to create a water heating system in a bathhouse. In this case, heating can be carried out in various ways - through a gas burner, boiler, central water supply. You can use a proven, albeit outdated, method: simply heat water on the stove. Almost any stove can be supplemented with a special hanging container. This is why you should use a stainless steel tank. We create a variety of tanks that have different volumes. In this case, not only stainless steel is used, but also other materials. The dimensions and configuration of the container can be either standard or non-standard.

We have been designing, manufacturing, and installing metal structures since 2005. During this time, we have accumulated enormous experience; we have designed, manufactured and installed thousands of metal structures of various kinds!

If we consider the characteristics of the metal that we use to create tanks, then the following material thickness can be used:

- 0.8mm,

- 1.0 mm,

- 1.5 mm,

- 2.0 mm,

- 3.0 mm.

Steel grades can be as follows:

- AISI 304 (08x18n10),

- AISI 321 (12x18n10t),

- AISI 430 (08x17),

- AISI 201 (12x15g9nd),

- AISI 409 (08x13).

Features of stainless steel

Tanks are created from a variety of materials, but stainless steel is recognized as the best solution. By displacement, such tanks can be:

- 20l,

- 30l,

- 50l,

- 100l,

- 200l.

Don’t be upset if you are not satisfied with this volume, we are ready to create containers of any size. Such products are perfect for both hot and cold water. The material is famous for its durability, resistance to physical influences, and corrosion. It is worth noting the small thickness of the walls, which affects the overall mass. Light weight is a huge advantage over analogues. Also, the low weight makes transportation and installation of the tank easier. There is no special load on the foundation.

Stainless steel itself is considered a plastic and aesthetic material, which makes it possible to create containers of any size. Therefore, you can be sure that our company will take into account all your wishes when ordering a tank.

About the advantages

It is necessary to consider the main advantages of such tanks:

- The material is not afraid of moisture, the products will last for as long as possible. Reliability and performance characteristics do not change when exposed to water. The bathhouse experiences high humidity conditions that are considered difficult for any other material.

- During use of the product, you will notice that it does not deform. Experts say that only minor deformation is possible.

- Excellent thermal conductivity ensures that the water in the container will heat up as quickly as possible. This fact will make it possible to significantly reduce water heating costs. Such tanks quickly release heat into the bathhouse. To eliminate this drawback, appropriate insulation can be used.

- Affordable price, our company strives to offer the most favorable conditions. Interest in stainless steel is increasing every year, making it more accessible.

Where to buy a tank?

If there is a need to select a stainless steel tank, then it is worth considering not only standard models; you can give preference to models that are created to order. You can always contact our company’s specialists who will help you choose the appropriate container. We use exclusively high-quality material that has proven itself on the positive side. Our material is highly reliable, has a long service life, and does not require additional maintenance.

Our company offers to create a variety of stainless steel products. These can be tanks of different shapes:

- oval,

- rectangular,

- square,

- with heating element.

We try to work as quickly as possible, providing orders on time. If you have any questions, you should contact our specialists directly. We will be happy to answer all your questions, help you place an order, and also choose the appropriate container parameters.

Tank reliability

In particular, it is worth highlighting the reliability of the products being created. Stainless steel prevents corrosion, so you can count on the product to last for a long time. Products such as bunkers are similar to tanks, only the latter are used to accumulate bulk substances. Making a tank may be required for a variety of projects.

Corrosion resistance is the main advantage due to which the products have become so popular. You don’t have to worry that the tank will rust in the near future. It will serve you for a long time. Do not limit the scope of application only to bath rooms. In addition to a bath, such a tank is used as:

- Tanks for storing drinking water for production needs.

- Household tanks intended for cold and hot water.

- Tanks for fuel.

Our products are characterized as simple, reliable and high quality. Such stainless steel products have attractive external qualities. After all, there will be no corrosion not only inside the product, but also outside. In this case, the containers will not have to be treated with any protective compounds. No maintenance is a significant advantage. The shelf life of the container is not limited.

Do we choose for ourselves?

When choosing a tank for your own purposes, you should give preference to containers that are not overly large. Small containers are suitable for individuals. A large tank is in demand among manufacturing enterprises. At the same time, a large product must be especially durable. But with us you can order containers of any volume. When choosing, consider the following points:

- It is important to think about such things as contact with food or drinking water.

- Prioritize additional process load. Often a heated tank is installed in bathhouses.

- Fire safety is also important; the degree of fire danger directly depends on the storage of flammable and flammable liquids.

- When choosing, do not forget that the geometric shape of the product can vary significantly. Choose the option that makes the most sense.

- Features of fasteners, it is important that the fastenings are as reliable as possible.

- Pipeline equipment and fittings necessary for use.

About the tank design

Any container is produced only after the customer has explained exactly what he needs. You need to decide on the design. The procedure for creating a tank:

- Cutting stainless steel blanks.

- Preparing the workpiece for the assembly process. During this process, edge processing, folding where necessary, drilling, and creating the necessary holes are carried out.

- Additional structures are assembled, these could be chimney pipes, for example.

- Welding tank assembly.

- Complementing the design with the necessary fittings.

- Checking the strength and tightness of connections. If the container has a significant volume, then it should be checked more carefully. The same applies to those tanks that are created for fuel. They can be used in transport, therefore they require special tightness.

When purchasing products from us, you can be sure of their quality. We sell products from the best materials that have been carefully selected. At the same time, you will be pleased with the affordable cost of the products, due to which you can save a lot.

Metal structures made to measure from ! To place an order call! Or write to email - [email protected]

Selecting the optimal tank volume

To choose a water tank for a bath pipe, you need to:

- decide on the material from which it will be made;

- select the dimensions and capacity of the heat exchanger based on the dimensions of the furnace.

The heat exchanger for the pipe in the bath can be made from:

- cast iron This device is resistant to corrosion and high temperatures, but the water in it will heat up slowly. To warm up you will need a large amount of firewood. However, the liquid will also cool slowly. The disadvantage of a cast iron tank is its large mass, which greatly complicates the installation of equipment;

Stove with cast iron tank

- enameled steel. Such a tank will heat up quickly, but the enamel coating of the tank is not durable. It reacts strongly to high temperatures;

Oven with enameled tank

- stainless steel A stainless steel sauna tank on a pipe is the most popular. Stainless steel is resistant to high temperatures. It is not subject to deformation. It is light in weight. Easy to install and does not require careful maintenance.

Stainless steel tank

The tank volume must be selected according to two parameters:

- the number of people who take a steam bath at the same time. In order to wash, one person on average needs 10 liters of hot water. By increasing this figure by the number of washables and adding another 8–10 liters required to park a broom, you can obtain the required tank volume;

- size of the steam room and installed stove. If you install a small tank on a large stove in a small section of the steam room, the water will quickly heat up and boil away. With the opposite ratio (small stove, large steam room area and large tank), the water will heat up very slowly, which will lead to prolonged combustion and the consumption of a large amount of firewood.

An equally important task is to determine the appropriate tank volume. The calculation of this parameter should be carried out taking into account the rate of water consumption per adult for bathing procedures, which ranges from 18 to 26 liters of water.

For a family of 2 people, it is enough to purchase a 50-liter tank, for a holiday with a group of 4 to 6 people - a 100-liter tank.

Factory models of water heating devices are presented in a wide range of volumes - from 20 to 200 liters. Electric boilers also have different volumes - from 30 to 100 liters.

How to choose a stainless steel tank for a sauna? on the Nedvio website

Question from a reader of our portal: How to choose a stainless steel tank for a bathhouse?

Answer: When choosing a tank for storing water in a bathhouse, you need to be guided, first of all, by three criteria:

- What material will it be made of?

- What type of tank and capacity size is suitable for your steam room?

- What method of water heating will be used?

Let's look at them in more detail.

Tank material

The most popular material for bath tanks for heating water today is stainless steel. And this is due to the following reasons:

- Stainless steel does not corrode. This means that the water will be clean, free of rust;

- The seams of such containers are usually sealed with argon welding;

- Elevated temperature and humidity are severe tests for metal, however, even in such situations, bath tanks made of stainless steel can be used without time restrictions.

As a rule, steel bath tanks are made from stainless steel grades 08X17 (430) and 8-12X18H10 (304), which have properties such as increased heat resistance and resistance to deformation as a result of high temperatures.

Selecting the type of tank depending on the method of heating water

At this stage, you need to determine how you will heat the water:

- via built-in heating element;

- or you will start heating the stove in the bathhouse.

After you have decided on this choice, you need to pay attention to the thickness of the tank wall, since its size determines how evenly the water in the container will be heated, as well as how long the water temperature will be maintained.

If you are going to heat the water in the storage tank with a stove, then its walls should be thicker than when heating water with a heating element, since they are exposed to higher temperatures. It should be borne in mind that the wall thickness affects the cost of the product and its weight.

Volume

To choose the correct tank volume, you need to estimate how many people will be steaming in your sauna at the same time. Another important factor is the volume of water that needs to be heated, as well as the time that may be spent on one or another method of heating the water to the desired temperature.

If you want to steam alone, then less than 50 liters of heated water is enough for one person. However, for the whole family or group of friends, you should install a tank for heating water in a bathhouse with a volume of more than 70 liters.

Installation method

Most stores offer models of sauna tanks that are attached to the stove chimney. The rest of the chimney is installed on the tank itself. In this case, the smoke passing through the pipe heats its walls, which in turn transfer heat to the water. Water is poured inside through the hole at the top and drained using the drain fitting.

There are also mounted tanks. They are attached directly to the wall of the oven and are heated with its help. At the same time, the tap of such containers is located very low, and this must be kept in mind.

To make it easier to choose a bath tank, it is advisable to consult with specialists. It is recommended to choose the volume of the product based on the number of washables and the size of the bath. So, to wash one person you will need approximately 8–10 liters of water, and the same number of liters are needed to steam brooms.

Buy a stainless steel tank

Did you find this article helpful? Please share it on social networks: Don't forget to bookmark the Nedvio website. We talk about construction, renovation, and country real estate in an interesting, useful and understandable way.

Regular metal

Steel tanks are never used in a bathhouse. When exposed to water, it instantly begins to rust, because it has no protection. It is impossible to apply a coating in the form of paint on the inside of the container, since during the heating process toxic substances that are unsafe for health will begin to be released into the water.

Thus, we can say with confidence that stainless steel sauna tanks are the best option for a number of reasons. Therefore, below we will take a closer look at the process of installing them.

We suggest you familiarize yourself with How to lay a vapor barrier on the ceiling which side

Maximum tank sizes

It all depends on the conditions that the customer specifies in his project. Height, width, volume of the tank, wall thickness, cost acceptable to the client - all this is taken into account when determining the maximum parameters of the product. Theoretically, our specialists can make a stainless steel container to order of any size.

Take advantage of the opportunity to manufacture stainless steel containers and tanks from a time-tested manufacturer - contact NAYADA. Call or fill out the form below and our specialists will contact you.

Method of heating water with a heating element or stove

What is more economical for heating water - heating a sauna stove or installing heating elements?

This is determined by the length of time visitors stay in the bathhouse during health procedures.

For example, if a tank of 35 to 60 liters is sufficient for a couple, then for a large company at least 120 liters are required.

At the same time, the rate of heating of water is affected by the thickness of the walls: for devices with a capacity of 50 liters - from 0.8 to 1 mm, for products over 100 liters - from 1 to 1.5 mm.

For a washing compartment with plumbing fixtures - a shower and a tap - it is recommended to install a closed-type hot water supply system: a heat exchanger is mounted in the stove, and a water tank is connected to it. For a small room, a design installed above the heating equipment is suitable.

Proper combination of a sauna stove and a water tank allows you to create a reliable and practical design that will provide not only quick heating of the premises, but also hot water supply. The selection of a suitable tank for heating water is carried out taking into account the design and operational features of the bathhouse.

Criterias of choice

The boiler power is selected depending on the area of the room

There is a large selection of sauna boilers on sale. It is difficult for a beginner to understand the features and differences of each type. The following criteria must be used:

- Heating area. The larger it is, the more powerful the boiler will be required. For baths, the thermal power value is 1.27. This means that to heat a room with an area of 30 sq.m. and ceiling heights up to 2.3 m will require 3.8 kW of energy every hour. In the absence of high-quality thermal insulation, this figure increases, as there will be heat losses. If you have a water heater, the value will also increase.

- Selecting the optimal type of fuel. In the case of a wood-burning sauna, you need to provide in advance a place where the wood will be stored. Raw material costs must also be taken into account.

- Material. Most often, boilers are made from different types of steel. The water heating tank is made of stainless steel for long-term operation. Cast iron boilers are not used in the bathhouse.

- Product design. Here we consider the presence of an external firebox and the ability to adjust the draft.

- Dimensions.

- Possibility of rational laying of stones. If a wood-burning sauna boiler is installed, it is important to provide space for placing the stone installation. Steam is released from the stones into the steam room when sprayed with water. When creating such a place, it is important to consider several factors. The larger the masonry volume, the more intensively the boiler works and retains heat longer. At the same time, more time is spent on heating. The second factor is the location of the basket in the boiler piping. It is necessary that the stones are heated in full and receive maximum heat.

The market offers models for each specific case. It is also possible to make sauna boilers to order according to the requirements stated by the buyer.

How to install a tank on a chimney pipe for a bathhouse

Chimneys must meet the following parameters:

- Resistance to soot, which can cause destruction of finishing materials.

- Compliance with fire safety requirements.

In this regard, modern buildings can only be equipped with those structures that fully comply with the presented requirements.

- Brick chimneys. Brick is a fire-resistant material with good heat transfer, which helps quickly heat the room and maintain temperature. But this material requires special skills for installation and needs regular cleaning. These characteristics make it impossible to install a water heating tank on a pipe. In this case, it is recommended to use an external model.

- Ceramic building elements can withstand strong heat, have a long service life, but are quite expensive.

- Asbestos cannot be used in chimney installations, as it does not tolerate sudden changes in temperature.

- Ferrous metal is not suitable for use in the required conditions, as it burns out quickly and weighs a lot.

- Stainless steel products are more resistant to temperature changes and have a more affordable price. Stainless steel chimneys are the most popular option. Due to low thermal conductivity, metal products heat up quickly and do not retain heat. This property is used to quickly heat water with minimal fuel consumption.

When building a bathhouse, it is worth thinking about the question of where the hot water for washing will come from. You can install a container with heating elements inside and heat the water with electricity. But why waste electricity if the bathhouse will still be heated in another way. In order to save money, it is advisable to install the tank on a bath pipe. Such a container will heat up as hot air passes through the pipe.

Tank mounted on a pipe

How to choose the right brand of stainless steel for a tank

When choosing a stainless steel tank, you need to pay attention to the grade of steel:

- If you need a tank for drinking water, the best choice would be AISI 304 or AISI 321 stainless steel. These grades contain nickel, which prevents the corrosion process, and in AISI 321, in addition to nickel, there is also titanium. Titanium is especially good when the water in the tank heats up, and since titanium prevents heat transfer, the result is less energy consumption and the water in the tank stays hot longer. Tanks made from these grades of stainless steel can be called “Eternal”, since the service life of these tanks with proper operation is practically unlimited and amounts to several decades. If you need a tank for drinking water, but the cost of a tank made from the stainless steel grades described above is high for you, you can order a tank from the AISI 430 brand. Of course, this brand is more budget-friendly, and the difference in the cost of tanks, other things being equal, reaches 25 %. This grade does not contain nickel, it is more susceptible to corrosion, and as a result, the service life is significantly lower than that of nickel-containing grades. But there is a little secret here: If your tank is constantly filled with water, then the corrosion process will be significantly slowed down, that is, it says that the welds of the tank are not exposed to wet contact with air, in other words, when you drain the water from the tank ( at natural consumption), the tank must either be refilled (the best option) or wiped dry (which is completely inconvenient, and in some cases unacceptable). By adhering to this rule, you can extend the life of your tank by more than one year.

- If you need a tank for bulk mixtures, without a doubt choose the AISI 430 stainless steel grade. The tank will not rust and will last a long time. By the way, almost all dishes (cutlery, ladles, pots, etc.), as well as decorative items in the interior, are made of AISI 430 brand.

- If you want to make a tank for stones in the sauna. AISI 430 steel grade is perfect. There will be no water in your tank, as a result, there will be no corrosion, and AISI 430 stainless steel itself, in addition to its low cost, has another undoubted advantage: heat resistance, it can withstand temperature fluctuations well, so feel free to choose this brand for a tank for stones in the sauna.

- A tank for chemical compounds or liquid compounds other than water. There is no clear answer here, but each brand has its own properties. For example, AISI 304 can be used for weak organic acids, but only at medium temperatures, or for strong inorganic acids, but only at very low concentrations and low temperatures. Suitable for food acids. It is strictly not recommended to use this brand for saline solutions. For formic, phosphoric and sulfuric acids, the AISI 316 brand is most suitable; this brand contains molybdenum and is very resistant to corrosion. The disadvantage is the high cost. If these acids need to be heated, then the smart solution would be to choose the AISI 316L brand; when using this brand, the container with the acid will easily withstand heating up to 300-350 degrees Celsius.

- If you need a tank on a pipe: AISI 430 steel grade is certainly suitable here. Often manufacturers, in order to even slightly reduce the cost of products, suggest using AISI 409 grade for the pipe and tank, but since the pipe usually has a very small metal thickness (from 0.5 mm to 1 mm), then the tank and pipe made of this brand will not last long and, as a result, you will still have to order either repairs or a new tank.

Peculiarities

The finished tank for the sauna stove is a separate elbow of the main chimney. Therefore, all work on its installation can be carried out independently.

There are two options for installing the tank:

- near the stove;

- on a pipe passing through the attic of the bathhouse.

Both options have the same installation scheme, however, in the latter case, the process of filling the tank with water is greatly simplified. Since the heat exchanger is not located in the steam compartment, a water tap connected to the pump can be connected to it. Therefore, it will be possible to supply water to the tank automatically.

Tank with water supply installed in the attic

Let us examine in more detail all the stages of installing the tank, when it is located directly above the exit of the chimney pipe from the stove.

First of all (if the bathhouse is not new) it is necessary to dismantle the old section of the chimney connecting the stove and passing through the ceiling.

Dismantling an old chimney

Next you need to do this:

- Install a piece of pipe at a height of 8 - 10 cm to the outlet from the stove. Thus, the tank will be hung on the pipe, and not installed on the stove. This piece of chimney is also necessary to form the most durable and airtight fastening of the tank. Pipe connections are made using special crimp clamps;

- if the tank pipe does not match the diameter of the chimney. then the installed segment is mounted with an adapter;

- the tank is installed so that it does not reach the top of the chimney by 20 - 25 cm;

- if necessary, an adapter to the main chimney pipe is installed at the top in the same way. If an adapter is not needed, then the top of the tank pipe is connected to the rest of the chimney with a piece of pipe of suitable size;

- The tank is additionally attached to the walls or ceiling of the steam room of the bathhouse.

Installation diagram for a tank with a volume of 80 l

Although today there are a variety of water heating devices, a regular tank for hot water in a bathhouse remains relevant. A rather significant advantage of this device is the significant savings on heating water from gas or from electrical appliances. Also, one of the positive aspects of a hot water tank in a steam room is that it increases the level of humidity in the air.

The main thing before buying a tank is not to miscalculate its volume. Some important rules will help you approach the choice of a tank correctly for its subsequent reliable and long-term operation. In particular, it is worth considering that one person in the bath will need from 20 to 25 liters of hot water. Therefore, if the steam room of the bath is small and designed for two people, then a standard fifty-liter container will be enough. And in the case when the area of the bathhouse allows a whole company to relax in it, then a hundred-liter tank is indispensable.

How to install and connect correctly?

During the process of installing and connecting a tank in a bathhouse, one of the main priorities is deciding how the water in the tank will be heated. The water in the tank can be heated either from the heat of the stove in the steam room, or using a heating element. The main factor here is the number of people visiting the steam room and their need for hot water. The thickness of the tank will also affect the rate at which the water heats up.

Connection diagrams for the water tank may vary. If there is running water in the premises, it is necessary to use a closed water supply system. For this purpose, it is most advisable to use a stove that has a coil, which, in turn, will be connected to a water reservoir and heat the liquid.

You need to connect according to the following instructions:

- The tank itself should be installed in the steam room and connected to the pipes using a coil.

- To achieve good circulation, it is worth connecting the upper part of the tank with the upper outlet of the coil, and the lower part of the tank, respectively, with the lower one. For this reason, cold water will enter from below, and hot water will be discharged from above.

- At the point where cold water will enter the tank, a safety and check valve is used.

- Then you need to set the threshold pressure for the valves at which they will operate. The drawings are presented below.

Thanks to this principle of operation, the liquid in the container will be heated using a coil. And after it is used, the tank will be filled with cold water again.

So, how to properly install a tank in a bathhouse? If the water in the washing room comes from a tap, under pressure, you need a closed water supply system. The most ideal option for this is considered to be a stove with a coil inside, and a tank will be connected to it. However, the following method can be implemented: the tank will be suspended on the stove itself.

A properly connected sauna tank will look like this in a sauna: the water in the register heats up and rises into the tank, where it gradually cools down and soon drops down into the register. This is how circulation occurs, and in order to improve it somewhat, it is better to take water from the return line - although this is not very convenient, since in this case you will have to wait a long time until the tank heats up normally.

But you can use water as soon as the stove is heated. However, it is more thoughtful and effective if a full-fledged ability to switch water intake from direct to return is thought out - this is much more convenient. If the entrance and exit to the tank is made from below, then the circulation will be somewhat slower.

We suggest you familiarize yourself with How to ventilate the floor in a bathhouse

And the diagram of such a process itself will look like this:

- The tank is mounted in the steam room, precisely under the shelves, and is connected by pipes to the stove coil.

- In the tank, for stable circulation, the upper outlet is connected to the upper outlet of the coil, and the lower one is connected to the bottom. Hot water will be discharged from above, and cold water will be discharged from below.

- A safety and check valve is installed at the cold water inlet - it is also called a blast valve.

- The automatic firing pressure of the explosive is set.

This whole structure will work in this way: the filled tank will be heated through the coil, and when warm water is consumed, it will automatically be filled through the cold water supply. As the cold water heats up, if it is not used yet, this pressure will constantly increase, and when it reaches its critical point, an explosive will automatically go off, releasing all the pressure.

If you do everything correctly, then the hot water in the bathhouse will be in the amount needed - and at a pressure that will be convenient for washing after the steam room.

Finally, you should remember that the most important thing when installing and using the tank is to follow all the installation features described in the instructions for the tank. In addition, you need to adhere to safety measures when creating a tank yourself. If you follow the operating instructions, the sauna tank will serve you flawlessly and for a long time.

Operating rules

In order for the tank to serve for a long time, it is required:

- install the tank following the recommendations described above;

- Fill the heat exchanger until the stove is fired. An empty tank may become deformed when exposed to high temperatures, which will lead to the need to replace it;

- during the cold season, do not leave water in the tank. This can also lead to its deformation;

- Rinse the container with water several times a year. To completely clean the tank, you can use specialized products that remove scale and other harmful substances. Topper 3031 descaler is ideal;

Tank descaling agent

- The drain tap must be used with extreme caution. It is not recommended to allow children into this process, as they may suffer injuries and burns.

Tanks installed on a pipe that removes combustion products are optimal solutions for bathhouses used in country houses. No electricity is required to heat water. This process occurs automatically when the sauna stove is fired. You can purchase a heat exchanger ready-made (the average cost of a product is 5,000 rubles) or make it yourself from any container (the process is lengthy, but all problems can be solved). However, such a heat exchanger requires constant monitoring of compliance with operating rules and timely cleaning.

- Choosing pipes and organizing drip irrigation with your own hands

- How to make a greenhouse from profile pipes with your own hands

- How to make a gazebo from profile pipes with your own hands

- Selection and installation of shut-off valves for water supply

- How to test pipeline shut-off valves

- How to insulate a water pipe: insulation options

- What and how to hide heating system pipes

- What pipe diameter to choose for heating: calculation technology

- Soldering iron for polypropylene pipes

- 5 ways to connect a cast iron pipe to a plastic one

Why is it better to buy stainless steel tanks:

- No centralized water supply is required (water can be filled either in buckets through the top removable lid, or using fittings built into the tank using a hose and pump).

- Our tanks are welded from stainless food steel with a thickness of 1 mm, which gives the tank strength, protecting the tank itself from damage and at the same time leaving it light enough for transportation and subsequent installation.

- One of the most important advantages of a stainless steel tank is that the water in such a tank does not deteriorate over time (does not bloom, does not smell, etc.).

- Stainless steel tanks are anti-corrosion resistant; the service life of such tanks is much longer than that of tanks made from other materials.

- The water in stainless steel tanks, in addition to the electric heating that these tanks have, is perfectly heated by the sun's rays, which will allow you to save on electricity on sunny days.

- Aesthetic beauty is an undoubted advantage of this product.

Useful tips

Many bathhouse owners need to paint their water tank. Moreover, if this is a handmade product, then you definitely need to give it a beautiful and presentable look. To begin with, before painting, it is recommended to thoroughly clean the surface of the container, both inside and outside.

To do this, you can use various abrasives. The surface must also be degreased to ensure good adhesion of the surface and paint during subsequent painting. If you are using an old container, there will likely be rust residues in it. This can be dealt with using a metal brush or an electric drill with a special attachment. A drill will help save time, effort and remove rust more thoroughly.

Immediately before painting, you need to ensure that the surface of the tank is completely dry and apply a primer. For painting, you must prepare a respirator and rubber gloves in advance for safety reasons. For the process itself, you can take brushes or a sprayer.

Currently, manufacturers offer a wide range of different paints for any surface. Many paints also contain substances that help protect the container from corrosion. Therefore, painting the tank provides it with additional protection and increases its service life. Specifically for a bath, it is better to choose paint with heat-resistant properties.

For cold water, a storage tank is often used, which pumps water inside using a pump principle. When the tank is completely filled, the pump turns off automatically. It is important to note that such structures create noise during operation. Therefore, for a comfortable stay, it is not recommended to install storage tanks in the steam room. Moreover, high humidity can harm such a system.

An extremely important factor for the tank is the correct water outlet equipment. You should pay special attention to it and choose pipes from high-quality material so that they do not leak. Otherwise, the water will drain constantly and will not have time to heat up well.

It is best to make a small partition between the stove and the metal tank. You can use asbestos sheet. This will prevent the walls of the tank from being damaged by the high temperature from the stove, which will significantly extend the service life of the metal.

If the weight of the stove and tank is large, then you first need to prepare a special foundation. It is usually done when the weight of the structure exceeds 600 kg. Cement mortar is not used for laying stoves. Sand and clay are used instead. The clay is soaked in water and then sand is added to it.

So, various models of water tanks in the bathhouse were discussed above. Each design has its own advantages and disadvantages. Therefore, the choice of design depends on the individual preferences of the bathhouse owner. To correctly select a container of water for the bathhouse, you need to decide on the design and volume of the tank. They can be built-in, remote and samovar on a pipe. Popular materials include cast iron and stainless steel. It is quite possible to make a container yourself without putting in a lot of effort and spending time and money.

To learn how to make a remote water tank, see the following video.

Built-in tank, remote tank or tank on a pipe?

Bath tanks come in various types. The most famous are built-in, remote and on a pipe. Each of them has its own advantages and disadvantages. Compare and evaluate which one is right for your bath.

Once upon a time, water tanks for the bath were always built into the stove - so that the entire lower part of the boiler was in the upper part of the firebox - the hottest. In this case, the bottom of the tank is in direct contact with the stove fire. Water from this container can either be drawn directly or removed through a special built-in tap.

Thanks to the excellent ability to install a special heat exchanger in the oven, the tank does not need to be tied to a specific place - it can even be installed in a washing room. According to all known laws of physics, cold water will fall into the heat exchanger, and hot water will rise back.

Sauna tank on a pipe

Of course, it also happens that the sauna is used not for a couple of hours at all, but for the whole day - for example, when washing, but time has already passed since the fire. Then the best option is a sauna tank on a pipe, where the water will be constantly heated to the required temperature. This is on the pipe through which smoke comes out of the furnace - and its temperature can reach 500 degrees. Such tanks can be quite large, since the heating area of the pipe is very large, and the water will heat up evenly and quickly.

There is also another advantage of this design - in this bathhouse, smoke leakage through a crack in the pipe is absolutely impossible, since the tank in this case serves as a full-fledged fuse.